Leaderboard

Popular Content

Showing content with the highest reputation on 02/27/20 in Posts

-

14 points

-

13 points

-

Made a start modifying the 4-link mounts. As you can see they originally hang quite a bit lower than the sill. New mount all welded up. Should be heaps strong enough! Cleaned up a bit. 17mm socket just fits through the channel to tighten/loosen the bolt. Might swap to Allen head screws, as the paint/underseal mightn't leave enough clearance. The lower arm is nice and level now. Next was to do the upper arm mounts. This is it all done coming through the floor under the rear seat. The seat just doesn't fit, but should be an easy fix by bending one of the wire spring things a little. Top arm angle looking much better. The arms should intersect pretty close to where I guessed the instant centre of the car will be. Just have the other side upper mount to finish off. Sent a bunch of stuff of to be zinc plated. Some didn't turn out as shiny as I'd liked, but not all of it's that visible and I think I'll get the engine and gearbox mounts powder coated any way.11 points

-

We've set ourselves the goal of having this run under it's own steam before Christmas, only time will tell if that's realistic. 21 head studs and 35 years of rain, not a great combo. We had the engine crane hooked to the head almost lifting the front wheels off the ground before she shifted! Minimal bore damage from what I can see. The valves aren't pretty, but what is on this so far. We'll keep tearing this down and drop the bare block to the reconditioners for closer inspection and start a parts hunt.7 points

-

All very painless. Lots of rust converter poured down the pillars and copper sprays for days Soz I remembered about pictures as I finished with the black zinc Fluked the rail, even the chrome clips on6 points

-

Door fits Opens without hitting anything Closes without hitting anything Is parallel with B pillar Is parallel with sill opening Sits flush everywhere All it took was totally reshaping the guard. Some spots were way out. The rear mounts had been welded on crooked. Added about 5mm in some places and skimmed a mm off in others Need to add a little at the A pillar, and probably add a little to the A pillar bottom edge itself. That lower bend/angle was different on the B pillar,door,and guard. At least it closes now FFS5 points

-

5 points

-

5 points

-

5 points

-

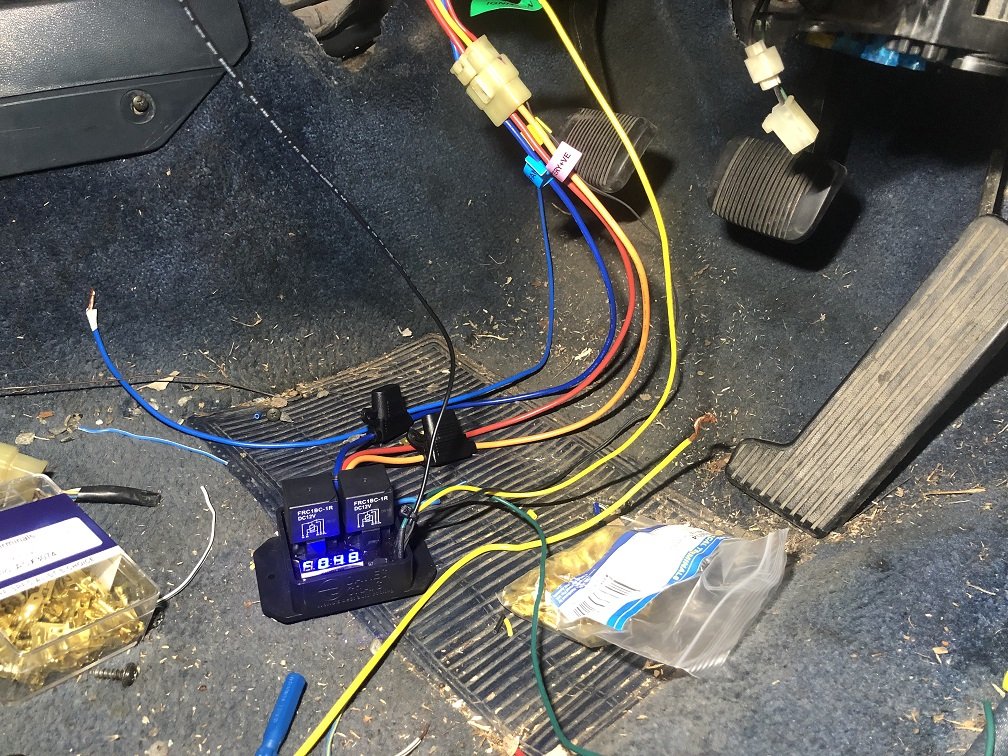

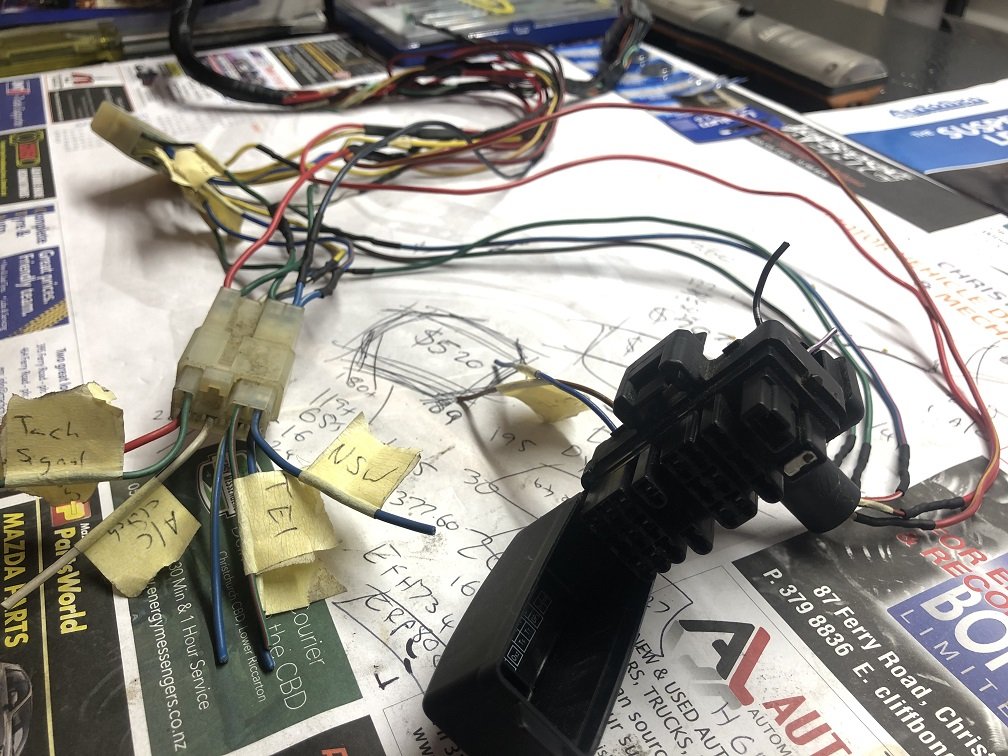

Next up is the fan controller. I got a 2 speed controller from Davies Craig, if the temp doesn't drop enough after 10 seconds of the first fan it kicks in the second fan. Also has an A/C trigger for when I get to that. I've seen a few of these mounted under bonnet but it isn't advertised as water resistant so I wired it up under the dash. That way I can have radiator temp while driving if needed. Once I mocked up length it's all been tucked under the guard with the rest of the loom. The early 1uz doesn't have a Te2 pin on the under bonnet diagnostic connector to trigger live data output, but it does have one on the ECU. I've gone and wired in a standard Toyota connector under the dash with Te2 for live data with the hope of getting a Toyobd1 Bluetooth dongle at some stage. They are hand made by a cool Canadian bloke so take some time to become available. Next up is Tach. Keen to keep the stock look inside so I swapped in the guts of a RX60 4cyl Cressida tach hoping that would give me an accurate reading. It did for about 5 minutes but then died. Swapping in the original 6cyl tach did the same thing. Maybe they didn't like the trigger signal from the ignition module? The newer style of tach from a 90's Corolla has the same bolt spacing for the card. I just needed to drill out the needle 0.5mm and fit a needle stop, the newer style has no internal limit to rotation other than the clock spring. Beautiful. I quite like the font on these older dashes the more I look at them. Next up is sorting the check engine light and possibly stealing a speed signal off the rear of the cluster for the ECU to avoid a pesky fault code.5 points

-

Ok so it was the swing arm that was bent. Got a second hand one and banged it in for a test fit, sat perfect! Stripped off all the old paint and surface rust then brushed on some rust converter to kill all the rust in the corners. Here is as it sits now. Next is stripping again back to bare metal and hit it with the etch prime then in the 2k black. Easy.4 points

-

Re water pump, I glue the gasket to the pump with a very light smear if rtv, then fit it and pull the bolts up tight from there. Give the o ring and where it sits a good dose of rubber grease and put it together.4 points

-

With the steering column out I quickly pulled the side cover off the steering box and a nice mixture of brown sludge, water and a little bit of oil came out. Nice ! No wonder the steering was almost seized. I'll strip the box at some stage to see if it can be saved as I'm planning to keep all of the original mechanicals intact in case someone ever wants to put it back to original. So with the column and steering box out of the way I was able to cut all of the riv nuts holding the outer edge of the hacked cover plate. I then carefully lifted the cover plate a little bit at a time whilst cutting through the Rhino line with a Stanley knife until I had gone all the way around. The final result doesn't look too bad.4 points

-

Umm... People say strange things? https://youtu.be/VXRBjEnpMwY https://youtu.be/-MEn4SMv-4s4 points

-

Filled about 50 holes in the engine and removed all the brackets I no longer need. Laser cutting a sheet of all the filler pieces made it way quicker and easier! Where the chassis rail kicks up at the firewall is a known place where cracks can form. There was already one about 8mm long on the passengers side. Made some gussets and welded them in. Found some previous repairs around the rear hatch on the body. I think they just ground out the rust spots here and then bogged it up. Cut out and welded new steel in there. Another one here, this time just a piece of steel brazed over the top of the rust holes. Fixed! As well as a few more bits around the seal. Picked up a pair off TA22 Celica fender mirrors from YAJ, that you can kinda see. I think they look good, but hard to tell when half the cars missing. Bought a Estima F series diff. Stripped in right down, cut off all the brackets and then noticed one of the housing tubes was very bent! One end was out by at least 10mm. Had a go at straightening it, wrapped some chain around the tube and some big u-channel, and then used a bottle jack and heat to push it out. Came out pretty good, close enough to then shorten it. Drew up a jig that held it all square and inline. Shortened it by 105mm a side, so it's the same dimensions drum to drum as the factory diff. Bought some MRP adjustable 4-link arms off @Cdarust Got a Altezza Torsen LSD head to swap in. Made some upper and lower brackets for the diff. Borrowed @oftensideways rotisserie. Going to raise the rear 4-link body mounts up. About 50mm higher for the lower mount, which should make the lower arm level and somewhere between 50-100mm higher on the top arm. The angles are currently far too much and I've gone this far so may as well, will be good to get rid of the lower body mounts as they're the lowest part of the car. It shouldn't effect the rear seat too much either.4 points

-

The old pics in your build thread don’t work. Can you put up a pic of the whole car so we know what all the people are talking about in your hidden camera vids?3 points

-

If you have new seals, put them in. Put rubber grease on the inner lip.2 points

-

My first thought was to try to uncover the heads of the bolts with a die grinder. Instant fail. Gotta tell you that Rhino liner is pretty tough stuff. Sticks like the proverbial. Looked underneath and discovered that the bolts fix into riv nuts, so thought okay if I can cut the riv nuts off with an angle grinder I should be able t punch whats left of the bolts out from below. Only problem is that the steering box is in the way so you can only get to one of the riv nuts. At this point I was getting pretty desperate and figured the easiest way forward would be to hack the cover plate to get the steering column and box out and then take to the riv nuts once the box was out of the way. With the steering and gear shift columns in place surrounded by the floor mounted clutch and brake pedals there isn't much space so I carefully drilled a whole lot of little pilot holes around the edge of the cover plate then followed up with a larger drill bit to overlap the holes. With the holes drilled all the way around and a straight line cut across with my tin snips it was easy enough to pull the remains of the cover plate out. Not one of my proudest moments, but needs must and I reminded myself that I'll need to fabricate a modified cover plate anyway as the HiAce steering and gearshift columns are much further apart than the Thames ones. The remains of the cover plate captured for posterity.2 points

-

Thats a cool shot on the beach there Rusti. pretty amazed that you would put the wrong hood on your 2022 dodgy wofed electric car tho WHO WOULD DRIVE THAT2 points

-

After morning smoko I thought I would crack into the next step of the "proof of concept" so I headed into the back garden to retrieve my mock-up 4Y motor out of the back of my second Toyota donor van. Loaded the motor onto my trusty wheel barrow and moved it under the back carport so that it is out of the weather. Grabbed the loose Toyota gearbox at the same time. First order of business was to take some measurements to see if the mighty 4Y will fit in the puny Thames engine box. Results of prelim measurements are as follows: Mighty 4Y - 510 mm wide at widest point. 670mm long from back of block to front of viscous fan. Thames - 505 mm wide at widest point. 654 mm long from back of block to front of fixed fan blades. So from the look of the width I should just be able to squeeze in the 4Y. From a length perspective I suspect that I may need to ditch the viscous fan on the 4Y if I'm going to retain the original Thames radiator. Nothing that an electric fan can't fix if this comes to pass. I still need to take some comparison measurements of the two gearboxes but I'll do that tomorrow.2 points

-

2 points

-

2 points

-

Cab off and away last night for wood rot repair. We are thinking of not painting the cab until after it's re-registered so the chassis tag & WOF sticker etc are undisturbed to make the process as smooth as possible. Now that it's short enough it can fit in the garage and we can hoist the engine out & get the chassis cleaned up. Keen to do some laps in its current state!2 points

-

I got lucky enough to be able to spend a whole night in the shed on Friday. So I kept welding until the pipe was finished... It was a massive effort. Severely underestimated. It was race day on Sunday, so I took both pipes along to back-to-back test them. I knew vibration was still going to be a big issue so was gonna run each pipe in one session and then ride an FXR for the rest of the day. The new pipe was good, the power band is a little wider and smoother, from ~9000rpm to about 11,700rpm, and I can tell its got a wee bit more power because now I get it to top gear before the end of the straight. Unfortunately it only got about 3 laps into the test before I could hear it getting louder, and as I pulled into the pits it got VERY loud. The vibrations had made the bolts come loose in the past, so I had tie wired them (loctite and spring washers wasn't doing it). Being tie wired, rather than rattling out, they have vibrated and pulled and stripped all the threads out of the barrel Time to balance that crank! I'm happy that the pipe has made a gain though. Now I'm going to do some research about nozzles to increase the stinger size and deal with its length.1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

Have rediscovered a bit of love for this the past few weeks. It's odd revisiting your previous work, I guess I was in a rush to get it running but there have always been numerous untidy things that have annoyed me about the car, so it's quite nice to make some improvement. The main source of annoyance was the wiring and the way it was run/cable tied all over the place, so I recovered the whole loom and rerouted most of it. This turned out to be a good move as there is still a lot of oil coating everything after the filter explosion disaster. The cable routing is better, will never be perfect but it is a lot more tidy. Before And after I also decided to follow some good advice from the discussion thread and got a Davies Craig EWP and controller. It may be slightly overkill for this application but I will be happy if the car runs at a reasonable temperature and I can eliminate the mechanical pump - this will probably require some fabrication as you cannot remove the impeller from the factory pump but I think I can get that sorted. Also wired the controller up and made a hinged bracket so the display can be folded up under the dash. Simple but does the job. Sensors aren't plugged in obviously, as I have no cylinder head. Will tidy the rest of the wiring once the pump and radiator are back in. Have been saving up for a new cylinder head, will probably source one from the UK. Going to be an expensive day but likely cheaper than buying a second hand head here then having it crack tested and built up etc. Time for a beer one thinks.... Cheers1 point

-

The last piece of the puzzle to date has been the engine itself. My search for that elusive horsepower led me down the rabbit hole of port timing. I raised the barrel 1.5mm Raised the exhaust port roof 6.6mm (+ the 1.5mm) Lowered the floor of the inlet port 10mm Cut the inlet side of the piston skirt 10mm This theoretically results in port timings of 195°Ex/128°Tr/185°In, however I haven't checked it with a degree wheel yet. Originals were 155.5°Ex/118°Tr (didn't bother to measure inlet because of the reeds). As well as taking the 1.5mm back from the top of the barrel, I machined the head about 1.1mm and used a thinner gasket to get from 17.5cc to 13.7cc (8:1CR to 10:1CR - Uncorrected) This gave me a squish band of about 1.8mm, which is about 0.8mm higher than I would like it to be. These engines have a bizarre piston port/reed inlet system that suzuki trialled in the 70's. Basically it just ends up being shit at both. So I've blocked up the reed port and massively adjusted the piston port to make it a piston port engine only. Comparison of before and after inlet port sizing: Have you ever seen someone precision machining their piston with an angle grinder? You have now!1 point

-

1 point

-

Cheers all for attending. Yeah sorry was late notice posting details, but the date is always the same 3rd sunday of January. (kumeu weekend). next new year meet will be 17th Jan 2021, put it in your calendar? Check the facebook link in first post, theres some pics in there already. Also looking to do an autumn meet this year, end of march or easter weekend. This page is usually updated first once i organise a meet ----> http://jap-olds.nz/1 point

-

Tomorrow! Weather is mint. Theres a bunch of cafes across from the entrance at 'the goodside' so park up and grab a bite/drink. See yas there!1 point

-

Another plug not often mentioned in conversions is the oxygen sensor check plug. usually found near firewall on exhaust side. it's a 2pin plug that connects to vf pin of ecu and e1 wire. Its not critical to the engine running but keeping it means you can diagnose a faulty oxy sensor. or even shorten wires back to near the ecu under dash where it could still be accessed.1 point

-

Ah sweet theres quite a few wires that may need to be integrated into the dash from the engine loom and that cluster diagram shows what connects where. Assuming with the 3au gone you'll be replacing the original engine loom that has oil pressure switch, water temp sensor and coil wire to tacho? Also adding in the check engine light and speed sensor from dash to ecu (gains 500rpm on the limiter at speed, well it did on a 20v anyway). Theres a plug near the ecu plugs on the engine loom that connects to the dash wiring, and all those things listed above and possibly the STA and COR might part of that bunch of wires. Sorry been a while since i did one. Does your main relay show on it somewhere a printed diagram of the internals and the pin numbers? From that you can tell which wires are the switch part and which wires are for the coil (coil inside the relay).1 point

-

Download and print out the matching pinout for your ecu (post it here too so we know what you're referring to). do the same for the ae92 ecu loom if possible. Could work it out from the pinout, but without knowing how it works it'll confuse ya. getting hold of a toyota yellow book workshop manual for the ae9 would be great, so you can understand the electrical systems. The alt wiring size should be fine unless youre running a big sound system or electric power steer, then the current draw increases heaps and youd want a bigger batt and alt anyway. the extra draw from a fuel pump and injectors arent huge. You'll be splicing out the alt wiring anyway as its on the other side of the engine. Also you're going from an external regulator to an internal. you can use the existing wiring but will need to change the lengths to suit the new position. could always upgrade the big white alt wire to the B terminal if you find the ae9 wire is bigger than the ae85. its in the ae9 engine loom anyways so youll prob end up using whats there and make it connect to the existing 85 alt loom or run it direct to battery, where ever that may be. If the new alt has a sense wire, then you may find it needs to be added in. external regs dont usually have it. its one of the 3 wires in the alt 3pin plug (not the charge lamp or ig wires) ant it also connects to the battery. Yeah you could just connect it to the big B terminal but youll get a lower charge voltage under load. i havent personally done ae92 loom yet, but if its anything like ae101/111 youll have extra stuff to deal with like a starter relay, which if wired correctly also connects to the STA pin of the ecu. The diagnostic plug has a few extra wirings in it but i cant imagine youd ever notice a weight difference by removing it. you can check things like if the oxy sensor is faulty without having to tap into a wire somewhere or the back of the ecu.. its right there on the firewall etc.1 point

-

What a slack guy! I've been pretty busy over Christmas, but got a chance to put a few hours into this lately. We finished pulling the nose to bits and sent the panels away for a bit of love. Next step is getting the body off so I can fit this thing in my garage and crane out the engine. The radiator really fought us coming out, it's away getting a re-core priced up. And the rear brakes are also getting rebuilt. Once that's done we should be able to push it by hand, prob for the first time in 20 years!1 point

-

Heads up. The usual late notice but, this is happening More details in thread once confirmed. https://www.facebook.com/events/215537258907263/ Date: Sunday 22nd January 2017. 11am - 2pm. (starts thinning out by 1pm usually) Where: University Ave, Massey Uni Campus, Auckland. lower tier carpark outside 'the ferguson' bar. Cruise meetup points at the usual places Greenlate McD's and Westgate outside ASB 10.15am, depart 10.30ish. Someone in attendance gather those there and make call to depart. For previous meet galleries and FB posts.. www.jap-olds.nz1 point

-

fixed! apparently can't change a private event to public. lesson learnt.1 point

-

1g-eu manual says: Use API grade SC, SD, SE, SF or better and recommended viscosity oil. Gives a chart for recommended viscosity vs atmospheric temperture. mega frozen balls to 10'C use 5W-30. but dont. -22'C up to 30'C you could use 10-30W. 10W-40, 10W-50 starts at -22'C ish up above 38'C 15W-40, 20W-40, 20W-50 starts at -12'C ish up above 38'C. seems 15W-40 is about the sweet spot for NZ temps. oil pressure (warm) at idle speed .. more than 0.3kg/cm2 4.3psi 29kPa at 3000rpm ... 2.5 - 5.0 kg/cm2 36 - 71psi 245 - 490kPa says when bleeding lifters, dont pull them apart. gives leak down test specs.. 20kg takes 2 -7 seconds/1mm after the first 2mm.1 point

-

naw, got the hots for david eh! yeah defo do an autumn meet Ed. It usually has to conflict with another event that time of year tho. also been suggested to do a premeet and cruise to caffeine n classics. kinda makes sense since they've taken every 4th sunday off the available dates. might have to start a pole on it1 point

-

Massey Uni Albany confirmed. lower tier carpark outside The Ferguson bar (gymnasium building). left at the uni round about and first left into parking area. Cruise: If people want to cruise together to the event. The usual spots to meet are 10.15am at Greenlane Mc'D's carpark or westgate shopping center outside the ASB. leaving 10.30am which is dictated on the day by the people in attendance. (Gather yourselves together and make the call). Cheers1 point

-

just awaiting confirmation of massey uni parking. facebook event page added https://www.facebook.com/events/175110509512814/ share share share!1 point

-

2015 Autumn Japanese and Oldschool Car meet When: late march? Where: possibly an east auckland reserve? I'm not posting deets here coz I cant edit later . So any conflicting events on 29th march? speak up now! last'ish weekend for daylight savings. Looking into proposed venues.. one being Omana Park, Maraetai. Want BBQ feed. who can assist? Discuss1 point

-

1 point

-

So yeah.. DATE: 28th March 11am- 2ish WHERE: Omana Park invite / share https://www.facebook.com/events/930230393684275/ https://www.google.com/maps/place/Omana+Regional+Park/@-36.8813806,175.0183402,15z/data=!4m2!3m1!1s0x6d72b5d87103d699:0xf00ef62249ccdb0?hl=en1 point

-

hit up alex user alfeinted as he may have a few tt141 wagon bits. he's in takanini. I may have some engine bits. Do you know why the pistons/rings scraped?? did you reuse the original pistons and rings.. or new rings? did they go back in the same bores and were the ring gaps checked? Im no engine builder... but pistons scraping like that may suggest not enough piston/bore clearance which wouldn't be a problem if bores were honed and original pistons fitted. which would suggest ring fitment wrong or ring lands cracked.. but unusual for all four to fail at once? also advancing the ignition would make it run hotter?1 point

-

true that. how many going to REunioin that would otherwise come along? Didn't wanna do it on easter weekend as too many peeps away. could bring it forward a week but i wont be there unless its in afternoon.1 point

-

prob too far out of your way.. my old man has his own wood workshop at Waiuku. He setup what was the franklin mens shed so the stuff on facebook is doable. Not sure if he's running evening classes anymore but i could ask? https://www.facebook.com/pages/West-Franklin-Community-Mens-Shed-aka-Arts-Man-Cave-/4046903562542751 point

This leaderboard is set to Auckland/GMT+12:00