All Activity

- Past hour

-

2026 McKenzie Moped melee. 27/2-2/3 2026.

RUNAMUCK replied to RUNAMUCK's topic in South Island Region

The longest gap between fuel stops is 156kms. In 2024, I did the whole trip without running out. (Unlike this year, when I ran out twice) -

No idea sorry mate. I know i polished the fucking thing at least 5 times during my apprenticeship though.

-

Daves new school holden shambles. (Is this project oldschool yet?)

Muncie replied to Muncie's topic in Other Projects

Well just learned if you blow an intercooler pipe off after the MAF turbo moves so much air through the system the injectors go max duty cycle and foul the plugs near instantly...... I rolled 1.5ks home and made it up drive and couldn't push brakes hard enough to not go into fence so handbrake to rescue! I may need to extend some pipework so I can get everything pushed in nice again, pretty sure I rushed the installation of the maf too maybe left a clamp loose. Goes great though!- 742 replies

-

- 1

-

- Today

-

Fuck did i have some issues getting it running. On the plus side I now know what every single wire on the ecu plug does, and that it's properly connected and working, as well as 90% of the entire cars looms. One i got the thing to actually run i thought the sensible thing to do would be take it for a drive. It's still running like a dog but I drove it anyway. Fuck it's choice, even though I've only driven it 10ks in a fucking cyclone I can already feel how amazing the thing is. I'M HAVING A BEER WHO'S WITH ME!!!!!!

-

2026 McKenzie Moped melee. 27/2-2/3 2026.

WankBankA100 replied to RUNAMUCK's topic in South Island Region

What's the distance between fuel stops on this gig? -

Do you know if they were the same company as the west island?

-

Ordered tyres for this. As its mainly going to be on road, I decided against knobblie s as wet white lines are not a good mix with knobblies. I have a pair of shinko 402s coming. Although its a dirt bike, these tyres will be good on road.

-

No worries. regarding the gearbox comment, was more meaning it is actually a g54 not something else with a different ratio. If you are certain its correct, then all good. just that it doesnt seem that 'short' in the ratio.

-

Thanks heaps for sacrificing some of your time to do the calcs for me @440bbm. I really appreciate it. I took the gearbox ratios straight out of my HiAce workshop manual, but that doesn't necessarliy mean that the detail is correct. I think your ideal of fitting a cheapie tacho is a good one, so I'll start working on that and will report back with some figures. Thanks again. Thanks also to @CUL8R for the links to the calculators.

- Yesterday

-

Yep nz made savage. Old boss had a 16ish foot one with a 115 yammie. Went hard as a ski boat.

-

Iwanttobeamole's Mates Mk1 Cortina - 4AGZE - Forgotten Princess.

yoeddynz replied to anglia4's topic in Project Discussion

Bookmarked! I loved my little 4agze aw11 back in the 90s so looking forward to seeing more on this. Also - that little blue thing with the engine in the correct place. Tell us more please. -

I havent torn off the floor but I assume it's all glass with ply/timber stringers. It says it is a Savage 350. It may be a NZ brand as it looks very similar to a Savage Bosun which every man and his dog owned in Straya but there are differences.

-

I have this nifty little Johnny in the wings which I quite like. Came from a one owner Barry who mentioned that he used the shit out of it but only in fresh water which seems to be true looking under the cover. Both barrels have 90+psi so I'm calling it good.

-

sweet boat! solid glass? what make?

-

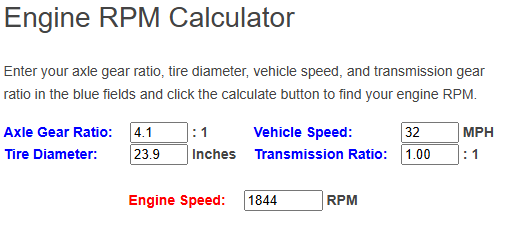

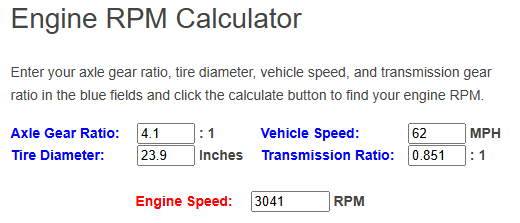

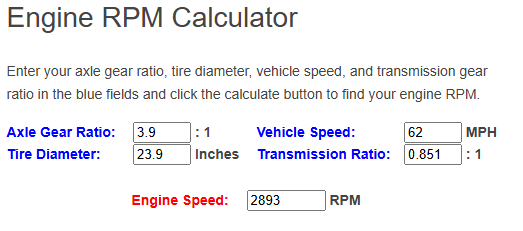

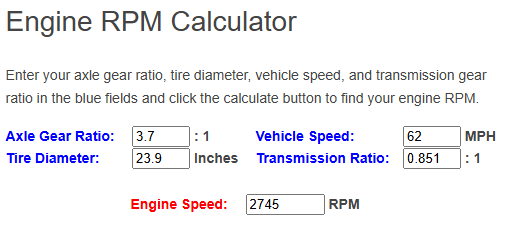

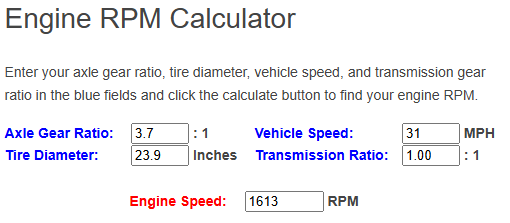

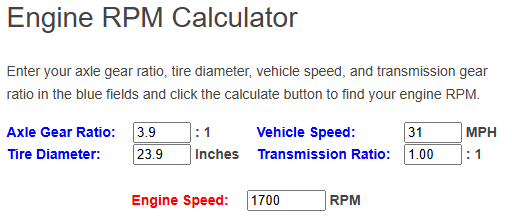

OK, sweet. Doesn't matter that you don't have an RPM counter, just makes it harder to verify the change to what you want with actual numbers. What gear do you use for around town at 50kms and obviously you're in 5th for 100. Here is your current setup. I have used 4th gear @ 50kph : 5th gear @100kph: So if we go to a 3.9 final drive ratio: 50 kph in 4th: 100kph in 5th: So if we go to 3.7 final drive ratio: 50 kph in 4th: 100kph in 5th: OK. There you can see the differences at nominal speeds. But what about 1st gear you say? I'm not going to do a @Roman spec graph for you which would be alot easier for your veiwing pleasure but the basics are this: 1st gear, 4.1 Final drive: 8kph = 1132 rpm 16kph = 2264 rpm 1st gear, 3.9 Final drive: 8kph = 1077 rpm 16kph =2154 rpm 1st gear, 3.7 Final drive: 8kph =1022 rpm 16kph =2043 rpm This would be easier, if I did an RPM to kph speed for you to see easier but because I'm lazy and cbf starting again, you can think about this the long way around it. But as it seems: 1st gear @ 20/21kph is the roughly similar revs at 100 kph with 4.1 ratio (2943 rpm ) 1st gear @ 20/21kph is 2800rpm with 3.9 ratio 1st gear @ 20/21kph is 2656rpm with 3.7 ratio Alot of funny numbers there. What I would do at this point, would be a cheap shitty RPM gauge that you can put in temporarily to see whats what. I question that you may be feeling like the revs are higher than you think which is not uncommon when you're sitting on top of the motor, not behind a firewall and alot further forward ( quieter ). The average becomes around 150 RPM in any gear in 0.2 change of final drive ratio. This also doesn't allow for wanting to change gears at different speeds with those without knowing what your RPM is in any gear/speed. Feels like dropping to a 3.9 may not be enough, but someone with more experience with your motor may be able to answer is the 3.7 going to make the motor suffer from torque. I'm almost about to question are yoou sure the gearbox is correct as the numbers don't look scary bad. TL;Dr - Not that certain I have actually answered anything or helped.

-

Cool bike, I like how the carb slide looks bigger then the piston...

-

Gibbon’s 1971 GT6 bothering - comment here

VitesseEFI replied to VitesseEFI's topic in Project Discussion

Nice pile of clean parts you have there! The chassis pic of the rear wishbone mount looks a bit like it’s had a minor shunt at some point and the wheel’s been hit with the force passed back to dent the chassis. Fairly typical Triumph injury but yours is a very light example. Double skinned at that point a some anti-crush structure. I have a much worse example in my carport that came with my GT6. Had 15mm of shims which was using all the bolt. Decided not to use that one! shifter mod looks decent. Interested to see how you mount it in the car. I struggled with the body on! -

OMC 4 LYF Y'ALL!

-

Well..... I wandered back out to get the garage to stir the porridge and but then got a bit carried away. The ultrasonic cleaner also heats so decided to try and unstick the piston in the caliper after it had been which I did successfully with some compressed air. Inside was gross, Also took to the master to see if I could get the circlip that retains the piston out. it's basically impossible to do without destroying the circlip but c'est la vie as the spainyards would say. As it turns out... it's a bit of a mess. I did buy a replacement master piston but for reasons I could never possibly understand the two sizes available were 14mm and 5/8th of three barley corns (ripe and dried laid end to end) I bought the 14mm. The old piston was not 14mm. Sooo. I've decided to bench the old master and grab a Chinese one for now. Maybe I'll revisit it later, but for not we're looking for progress not perfection. More... less soon.

-

Presents? thingsorganisedneatly So checked off the order and it all appears to be here. I decided to look into the front brakes. They do not look neato. A bit more disassembly of the master Turns out the ultrasonic cleaner really likes to mess with my phone camera, but this is what under the reservoir looked like. The brown stuff is dried brake fluid and it came out like very shitty cocaine. And the caliper Into the porridge they go! Side quest has progressed. I got the carbs cleaned up on the GSX500e and it now runs very nicely on all four cylinders at all revs. Still doesn't like a cold start very much but it's.. better. Booked for VTNZ to get certified on Monday so.. fingers crossed that exhaust isn't too loud. More soon.

-

For the purposes of getting the thing road legal I'm quite glad to report that it is in fact a muffler. Still sounds awesome though. I'll get a vid this weekend.

-

This is a good calculator to help you out; https://spicerparts.com/calculators/transmission-ratio-rpm-calculator https://tremec.com/aftermarket/resources/gear-ratio-calculator/

-

Gonna try and get a plate on friday. Wish me luck!!

-

Thanks heaps for the reply @440bbm and also for the offer of assistance. I have looked at a few of those online calculators, but the biggest issue that I have is that I'm not running a tacho in the van, so I've got absolutely no idea what revs I'm actually doing. What I was hoping to do was to work out the optimum ratio by using my gearbox ratios as a guide. So at the moment 1st gear has a ratio of 3.928 and it's hardly worth using with my current 4.1 ratio diff. The van comfortably pulls off in 2nd gear which has a ratio of 2.333. So to my simple way of thinking if I could find a diff ratio that would effectively turn my 1st gear into 2nd and so on that would be ideal. Sadly maths is not my strong point and I couldn't find an online calculator that could work this out for me. My gearbox is a Toyota G54 (5 speed) with the following ratios: 1st - 3.928, 2nd - 2.333, 3rd - 1,451, 4th - 1.000, 5th - 0.851. My rear tyres are 225/50/15 which works out at an overall wheel diameter of 606mm if the online calculator that I found is to be believed. Any guidance that you can provide would be greatly appreciated.

-

Dropped frame and bars to a powder coater ..