-

Posts

11,673 -

Joined

-

Last visited

-

Days Won

2

Content Type

Forums

Downloads

Events

Gallery

Everything posted by flyingbrick

-

Good morning mate. Wow, have not been here for some time So dunno if you follow the two wheel stuff but the timeline was like. I buy a 525 KTM with the goal of getting it road legal I find out It cant be made road legal in NZ as its a SA import with no papers I buy a road legal 530 KTM with the agreement (with wife) that I sell the 525. I find a bloke that will swap both the 525 and the 530 for a Hayabusa. Wife is like, "fuck you, thats not how this was going down, you had 4k for a bike not 8k, we need that money" I hurriedly sell LS/car parts in an attempt to raise the 4k that i'd have otherwise made by selling a bike. It works. She's kinda happy but not really. I get a hayabusa. tldr I sold most of my really cool shit, but dont regret it. The ute (And beetle) are definitely on my mind and get thought about a few times each week. When things return to normal (And im not living in the shed) I'll be finishing off the last of the rust repairs and putting the kitset of parts together. No idea on what the engine will be but the allure of an LS has kinda been lost now that I have something fast.

-

Wow had no idea they were still assembling cars here in 98. When did that end?

-

Kinda. The laser comes out of my japseye

-

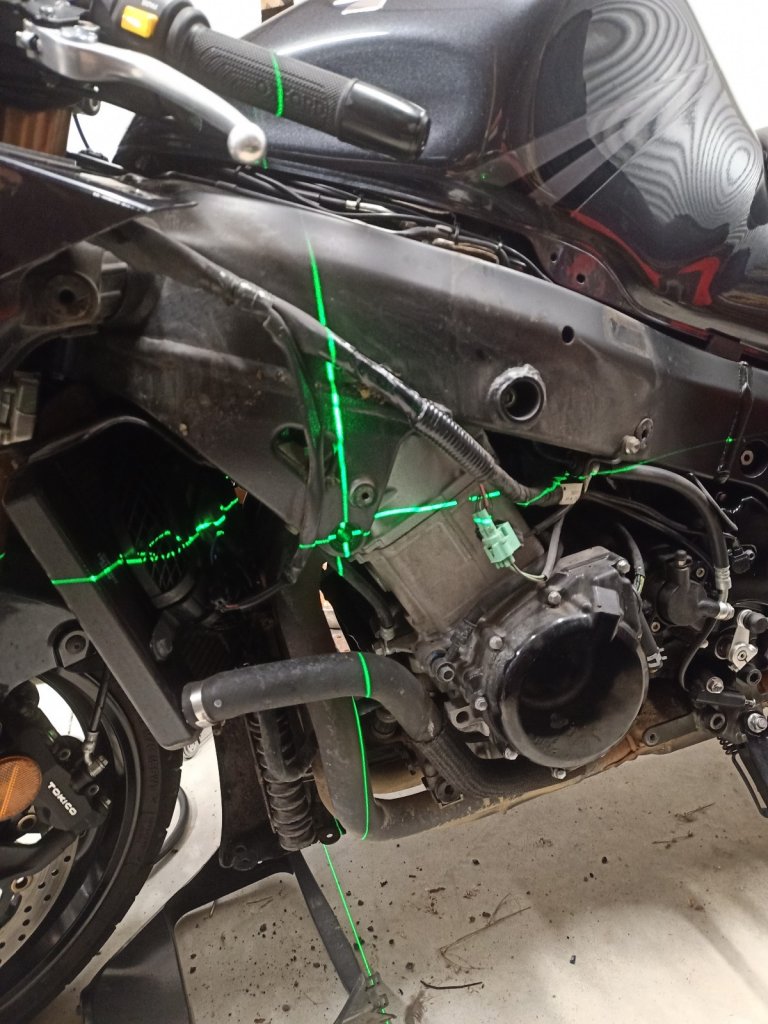

Best to plan for the worst, but hope for the best. These are frame sliders and bolt into the front engine mounts. The hardest part of installation is precisely locating the required 25mm hole. The manual recommends a laser and I have one from the shed build that I never thought would have an automotive use. Step one, take off fairing and shine laser cross onto engine bolt hole location. Step two, re install fairing and drill a 25mm hole where the cross indicates. Step three, bolt down the aluminium spacers and plastic sliders. I went to 40 nm and used medium loctite. The laser works bloody well, look at the nice fit!

- 175 replies

-

- 10

-

-

-

Damn that's incredible! You gotta be happy with that

-

Personally I only like the idea of having them potted in epoxy or something (iv used hot glue before) as its all then 100% waterproof and protected

-

I did see a comment from someone that these have a groove for tie wire, but I think I may have used that groove as a cut guide when I trimmed the ends off.

-

Yeah I'm just happy I found something to stick them down securely. The Inner sleeve is a shit greasy plastic that the superglue had zero adhesion to. It just flakes off. I think I'd have died of old age before these grips will need replacing from wear, knock on wood lolololol

-

Installed some Oxford heated grips- the grips and controller/wiring is all quite nice but the included tube of superglue is a complete waste of time as both grips came loose before I'd left the drive. These are not like regular grips and have a hard plastic inner sleeve which does not shrink against the bars like usual. I pulled the grips off again, roughed up the bars and plastic sleeve, then glued in place with a thick smear of liquid nails. Completely the wrong application for that glue but it seems to stick like shit to anything and everything, and the grips sure don't feel like they are ever going to move now. Let's hope the glue doesn't soften with heat.. Lol. The controller has some voltage sensing thing too. Its connected direct to the battery but will not operate unless the motor is running. Guessing they need a minimum of 13v or something to turn on. This is a great feature because I'd say they could drain a battery pretty quick if the motor wasn't going. Check out the huge factory bar end weights which screw into the solid aluminium bars. They entire handlebar plate thing is also rubber isolated-lots of consideration given to comfort and one of the many reasons they are a bit tubby.

-

Got my cast off 1.5 weeks ago and have had bike out for half an hour since then. Have been pretty cautious as after 12 weeks restrained there was very poor muscle control and it felt super super fragile, but grip strength is improving very rapidly. We know this, but god damn shits amazing. In general I don't speed, but like acceleration and the sense of unlimited power- and this thing delivers for sure. Also very easy to see why these end up with huge kms on them compared to most 600-100cc superbikes-so easy to live with and manage. Big trip coming up and so of course i had to make the acquisition of a luggage rack far harder than usual. I had time on my hands and like a challenge, plus thought I could make something a little more aesthetically Drew outline in cad and printed/test fit then made alterations. Had a good friend cut from alloy. Ended up being done from much thicker aluminium than originally planned but this gave me the confidence to get a bit artistic with the design and weight removal. Then got a tiney router bit with tiny 4mm guide bearing and ran it over both sides to cut a sweet chamfer. Its had a fair bit of finish sanding/filing since these pics to remove hard edges, but now want to DIY anodise it dark grey/black. Its turned out pretty good so far I think. Swaps between aero hump/passenger seat/rack in a few seconds just with a key (all other racks use bolts, but they do allow a pillion where as mine doesn't, and they are also big square things with no real thought given to design) Also started it last weekend and had a really loud and alarming clutch rattle. Shut it off pretty quickly, opened up the clutch and ended up loctiting and torqueing all of the fasteners (this particular year omited factory loctite and loose bolts there is a problem) Sounds gone now but research tells me that these things are renowned for having rattles there due to their variable clutch torque limiting shit being pretty sloppy. Anyway, until next time Bye.

- 175 replies

-

- 16

-

-

Which part is bespoke? the input to the gauges or the gearbox output?

-

Hey man. This does not answer your question, but I think SpeedHut sell adaptors to fit most gearboxes that convert mechanical gearbox output into pulses to suit their speedo's (and probably many others). Might be easy compared to factory stuff (Or exactly the same, no idea)

-

Yeah so you buy a backing pad to fit either your standard grinder (has a nut on the back) OR a die grinder (has a little shaft on the back) Grinder one looks like this. Then you buy either sanding discs like this Or softer abrasive discs like this. The benefit is that there is no center boss to get in the way so the pad can be put flat on the surface. Very good and much better than flap discs for keeping anything flat.

-

Fibreglass, Carbon Fibre, Paper Mache - The composites chat thread

flyingbrick replied to Roman's topic in Tech Talk

Yup he's amazing. Never seen someone work so much -

Help me get these rings on my shaft?

flyingbrick replied to mikey's topic in Upper North Island Region

Create a frame to maintain alignment and add tail fins to ensure correct orientation. Then drop from hot air balloon -

hey old comment now but you said you wanted to get some flap discs. They are good, but for clean up after welding like that, Rolok discs are heaps better because they let you put a flat rotating face down onto the flat panel. Seen tons of bits fucked by people with flap discs when they remove/gouge the original steel! Cool project overall, looks like you are doing a bloody great job.

-

Oh man, I had a catch up. Saw the rust and was like omg... And then super happy to see you fix it and get it all back together ASAP. Well done!

-

Damn that is beautiful stuff! A few mistakes but who cares, I'd bet you can fix those bits with nobody noticing unless you pointed them out. Also, it's OK if the hole is too small. You can be upset when it's too big lol.

-

Any imperfection in the sand is only going to make it look more authentic! bloody amazing, so now you have to transport it carefully to the foundry?

-

I enjoy your videos, wish you put up more showing the final product. I need to see the guitar body and whatever those ply bits assemble to make

-

Do you have to worry about your components looking too perfect compared to the originals?

-

Tortron's 1985 DR200 *they call me mello yello*

flyingbrick replied to tortron's topic in Two Wheels

wow, that DR looks great!!!! Hows it go on the road compared to the GN? be lots more usable with the extra capacity?