-

Posts

11,673 -

Joined

-

Last visited

-

Days Won

2

Content Type

Forums

Downloads

Events

Gallery

Everything posted by flyingbrick

-

Need to check my spreadsheet but I'm up around 35kg off. It just gets confusing as many things like exhaust are so many iterations on from factory. Need to weigh the whole bike. I can say it's massively noticable when riding. Compared to a factory one it's like a whole new bike. I also cut down my levers and welded new balls on the ends to make them look legit. Mostly just because they looked cooler About 2% of the brake removal crowd does it for the right reasons. Very common for Americans to take off one front caliper and disc, and the rear caliper and disc, just to get the look they want. It's seriously stupid.

-

Replaced the steel engine mount bush things with aluminium. Shitty job to do for bugger all weight saved.. had to cut a socket into a tool to remove the factory pieces. 150g removed

-

Removed the heavy steel bracket, lower aero tray and voltage regulator mount thing, then relocated the voltage thing up into the tail. 622g saved

-

I deleted the oil cooler and blocked off the outlets. These bikes do not need the oil cooler even when turbocharged and making 600+HP, so although it's a strange thing to remove- the benefits are numerous. 2055g saved and it's now a whole lot easier to change the oil filter as the oil cooler isn't blocking access

-

I spend ages thinking about where else I could save some weight and the best way to make this. I wouldn't do it this way again, but it's good enough that there is no reason to change it now. The factory fuel tank mount incorporates a hinge and is quite heavy steel The hinge is cool because it means that you only have to undo two seat bolts and two tank bolts to lift the tank up (to access the airbox) My new tank mount does not hinge, so rather than four bolts you now have to undo 6..not really a big deal. This saved ****TBC**** I have done a fair few km with this bracket now, so I am pretty happy with it. I was initially a little concerned about loads (you brace yourself against the tank sometimes) but it's rigid and STRONG.

-

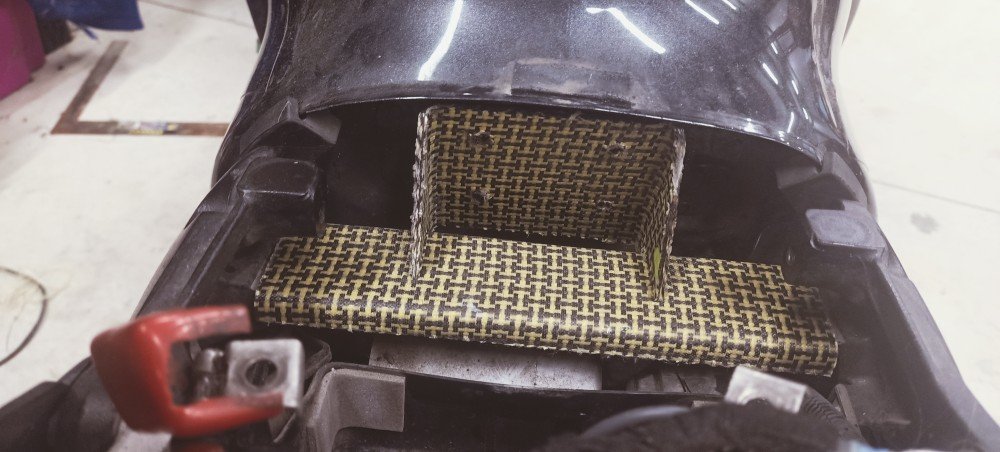

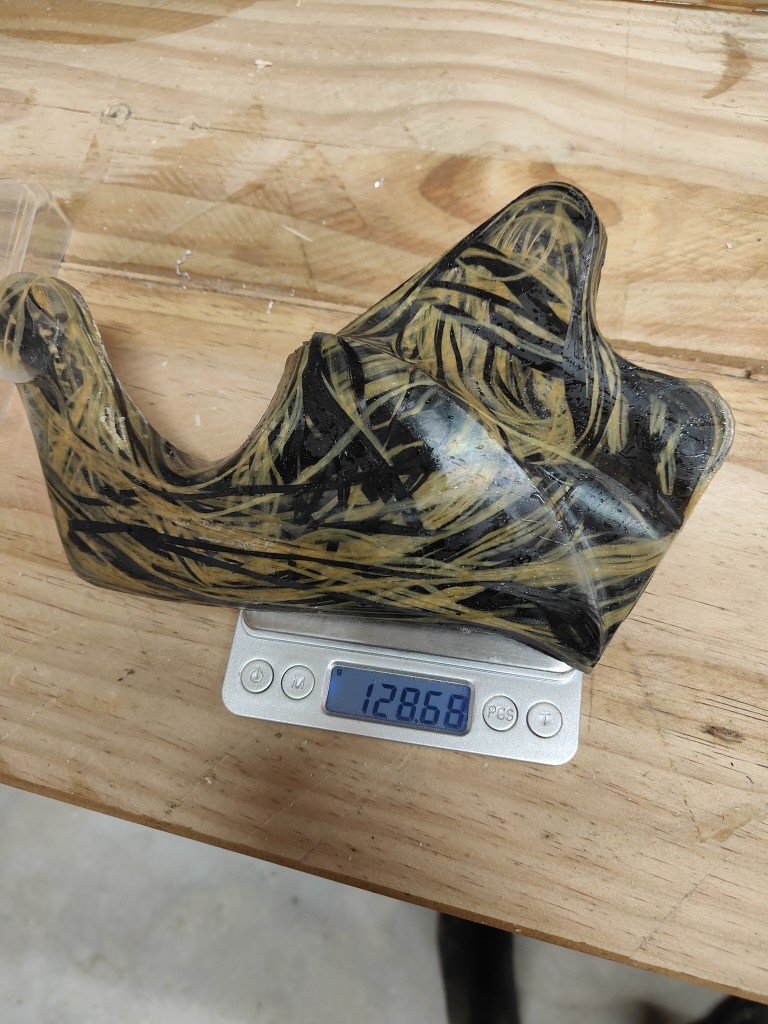

I had drilled holes in my factory exhaust mounts to try cut some weight out. These were cast aluminium and 680g each. Holes were cool but when I changed to a single sided exhaust there was another opportunity to drop weight. I used filleting wax to smooth out the cast part and fill in the holes id made, then poured a mold in silicone, then made my own exhaust mount using a mixture of carbon and kevlar. I oriented the strands appropriately so that it was the strongest possible (well, as strong as is possible within my garage) component, with strands wrapping around the full part and around the mounting holes etc. it is STRONG.. The single component weighs 129g, a saving of 551g...but as the left side is no longer needed at all, there is a total saving of 1234g Really didn't like the look of it so painted black in the end. Made a carbon fiber heel guard too.

-

I bought two old mufflers off trademe cheap. One was full titanium but buggered from a fall (was worse irl than it looked in the photos) The second one is a super cool old carbon fiber muffler. Unfortunately the carbon one had a hole from an impact, was too long and was sized to suit a little motor. I patched the hole with carbon fiber on the inside, cut both ends of the carbon body off to shorten the whole thing (the ends were all messed up) and then put the bigger guts from the titanium muffler into the carbon one. It's on my list to tidy up one day but for now it looks alright and works well. Since I replaced two heavy (but still lighter than OEM) mufflers with one carbon muffler the weight saving overall is HUGE. gets confusing without checking spreadsheet but approximately 15,000 saved vs factory mufflers ****to edit later.****

-

Bought a very cheap set of yoshimura stainless extractors. Unfortunately they were missing the head flange things so I cut the pieces off the factory headers, re sized the tubes in the press by pushing through a torpedo so that they slid into the extractors slip joints nicely. I was quite proud of how well these cleaned up- I soaked the stainless in a bath of Citric acid for a few days and they went from shit to nearly new. 3900g saved from extractors alone.

-

Removed the clutch covers external dampener weight thing to save 228g It's covered by the fairing anyway so it's a waste of space

-

-

Hah, haven't been here for ages. *Numbers below may change once I look at spreadsheet but let's hope I'm reading my phone notes right. Removed the smog stuff and fitted some nice cover plates to save 449g

-

Discuss here about Yoeddynz's little Imp project...

flyingbrick replied to yoeddynz's topic in Project Discussion

Actually yeah be better to get some paper bags of concrete, empty the concrete out the back and then fill with beanbag beans lol -

Discuss here about Yoeddynz's little Imp project...

flyingbrick replied to yoeddynz's topic in Project Discussion

How big is your trunk Alex, if its not too huge ill look at doing one in carbon fibre -

Discuss here about Yoeddynz's little Imp project...

flyingbrick replied to yoeddynz's topic in Project Discussion

I had to read that whole FB chat and put my 2c in -

Discuss here about Yoeddynz's little Imp project...

flyingbrick replied to yoeddynz's topic in Project Discussion

The company I now work for is producing a great product with zero cons for the consumer. The Facebook page is full of fuckin Karen's putting their 2c in about how it's shit. Every single post I need to bite my tongue haha -

Its been a total pleasure being present for parts of this build.

-

Discuss here about Yoeddynz's little Imp project...

flyingbrick replied to yoeddynz's topic in Project Discussion

most definitely a specialist foundry if they are doing 90% of the worlds blanks. Wouldn't be a small operation. -

Old post, but I'd like to say- It can be amazing which things ARE controlled by canbus these days. It would not at all surprise me if brakes and tail lamps were more often than not canbus these days. Even tail lights on new motorcycles can be canbus. the BYD's horn has an annoying delay which im sure is because its controlled via canbus. Its definitely not hard wired like traditional.

-

I have done some pretty cool things with arduino but seem to forget things just as fast as i can learn them. I have no idea what he is talking about most of the time but the moving lights are pretty.

-

came here to ask why they had positive camber- reason makes sense! Might look weird if you reduce it (I know you wont anyway because you want this thing to be as close to origional as possible)

-

Discuss here about Yoeddynz's little Imp project...

flyingbrick replied to yoeddynz's topic in Project Discussion

no theres nothing in it, just plain water. -

omg, cant believe the cost of a welder these days. I have the model below that too- it welds excellently. Must say I have bitched about it a fair bit but it's only become a dick since I switched to .6mm wire and I started getting birds nests but thats an easy fix (back to bigger wire)

-

SUGGESTIONS/RECOMMENDATIONS FOR VIVA CONVERSION

flyingbrick replied to La Viva 71's topic in Project Discussion

my 2c. Google for conversion / swap kits and buy whichever motor has a kit available. I think anything that removes a hurdle (like engine/gearbox mounts) is worth its weight. -

Discuss here about Yoeddynz's little Imp project...

flyingbrick replied to yoeddynz's topic in Project Discussion

this hurts my head, but just FYI incase its relevant in the slightest- there is a company in australia called subie gears that supplies parts to reverse rotation of WRX gearboxes. One of the parts they supply is a backwards ring gear (I think). If its ever an issue, they may be able to help. -

Holy shit! Hah! Fark there was a lot of scope for that to go bad during ya ride