-

Posts

475 -

Joined

-

Last visited

toy-mota's Achievements

Advanced Member (3/5)

935

Reputation

-

I recently just picked up a cabinet from machinery house. Pretty much the same as the ones here. Siliconed every panel before bolting together. Roughly tried the gravity hopper with a funnel inside the blast cabinet hooked up to the gun , next il try it above the blaster. i started blasting my sump, looks like it may take awhile. what size compressors are people running?

-

Rocker cover finally finished and turned the granvia rear sump and pick up to a midsump setup. oil pickup is as high up as i can get it ,4mm off the conrod

- 16 replies

-

- 14

-

-

Speedhut 4inch gauges turned up today. One is a quad gauge with oil,water,fuel and amps. These will fit with little mods to the factory dash i have a speedhut speedo already installed in my ms65, so a No brainer in doing it again, easy wire up and mounting , able to customise it and if i change wheels/diff i can recalibrate with a push of a button, life time warranty also

-

crossmember is in place for now. the larger pipe near center is for the 3inch exhaust to pass through. motor mounts made just needs welding. oil pan and pickup mods are next . All needs to clear the steering .

- 16 replies

-

- 17

-

-

Rocker cover nearly finished.need to go to pick a part and find a steel oil cap and use the wing lock style ,adapt to the 70s toyota one, also weld in the corresponding side to the cover. The pressed square patch on top is for a 4m style sticker but say 1kz. superpro bushes arrived. Will fit them one day.

- 16 replies

-

- 12

-

-

Looking at going the full hog . Body off chassis.zinc plate all bolts and brackets . Im thinking a janekits zinc plating kit from oz

- 16 replies

-

- 15

-

-

Progress is going good on the wags currently.engine is in and roughly mounted. Just finishing off the gearbox crossmember. set of superpro bushes are on the way for front/rear suspension.i have ms112 front hubs and discs and ms112 rear diff setup to go in. also i have ordered 2 4 inch speedhut gauges .1 a speedo and the other a quad gauge. Fuel/temp/oil/volts .should fit into the original dash nicely custom rocker is almost finished. Just need to sort oil cap and breather. Posts will be milled down to height and stainless dome nuts to hold it down.

-

Has anyone looked into or used Jane kits from oz? one of there 10litre zinc kits is $450aud shipped https://janekits.com.au/

-

So this happened. ive purchased a toyota granvia with the 1kzte to shoehorn into the wags . il keep the box and fuel system also But to keep with the restomod theme, i plan to not make it look like a kz . Also will make custom intake/exhaust manifolds and intercooler. plan on keeping the a/c. I have an old aftermarket under dash unit

- 16 replies

-

- 25

-

-

-

Random slightly cool stuff you built but not worth its own thread, thread

toy-mota replied to h4nd's topic in Other Projects

I got 2.0 done today . Uses an old truck air tank shortened up as the firebox . 4 and 3 inch air inlets and 3inch outlet. Heat shield around chamber pipe to keep it hot -

Random slightly cool stuff you built but not worth its own thread, thread

toy-mota replied to h4nd's topic in Other Projects

So i dabble in charcoal cooking and have a stack of wood (blue gum,apple) so thought why not make my own charcoal. after some youtube-ing i found a style i liked and could make. its made from a 55kg grease can . With a 3inch inlet ,4 inch fire box and 3inch flue which is all in the center and sealed. Then a tube from the top of the drum to the firebox inlet. This lets the wood gas self fuel . takes around 4/5 hours to make a drum load. currently working on 2.0 , more fuel more air more heat -

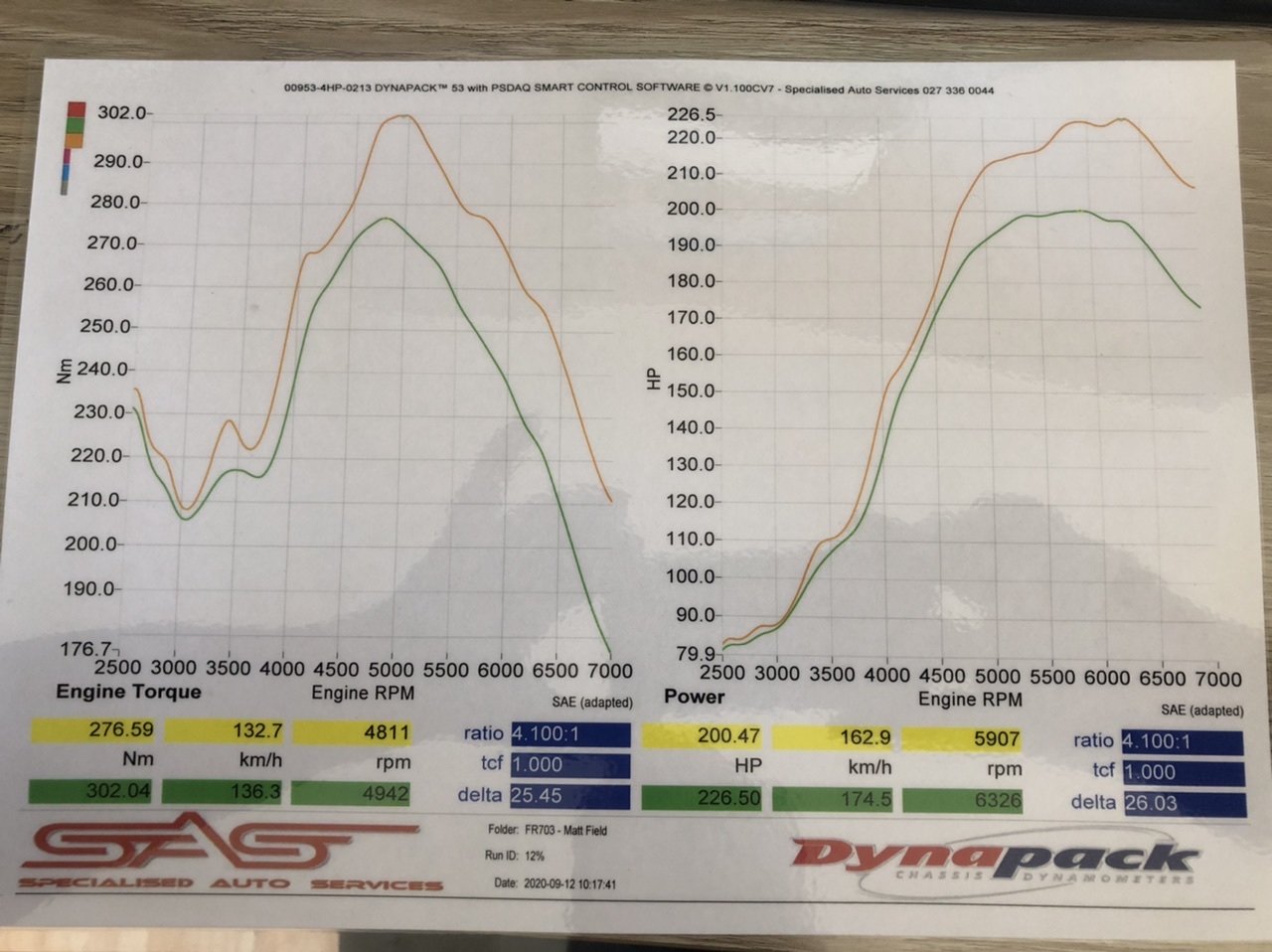

I put the crown on the dyno at SAS here in chch . To get the motor running right as it was only road tuned . 2 hours on the hub dyno and i got this... 200hp aircleaner on 226hp aircleaner off im happy with it, i wasnt chasing HP , its just a big jap cruiser with abit of power and noise vid below https://youtu.be/cMzoZRc_0OM

- 79 replies

-

- 17

-

-

-

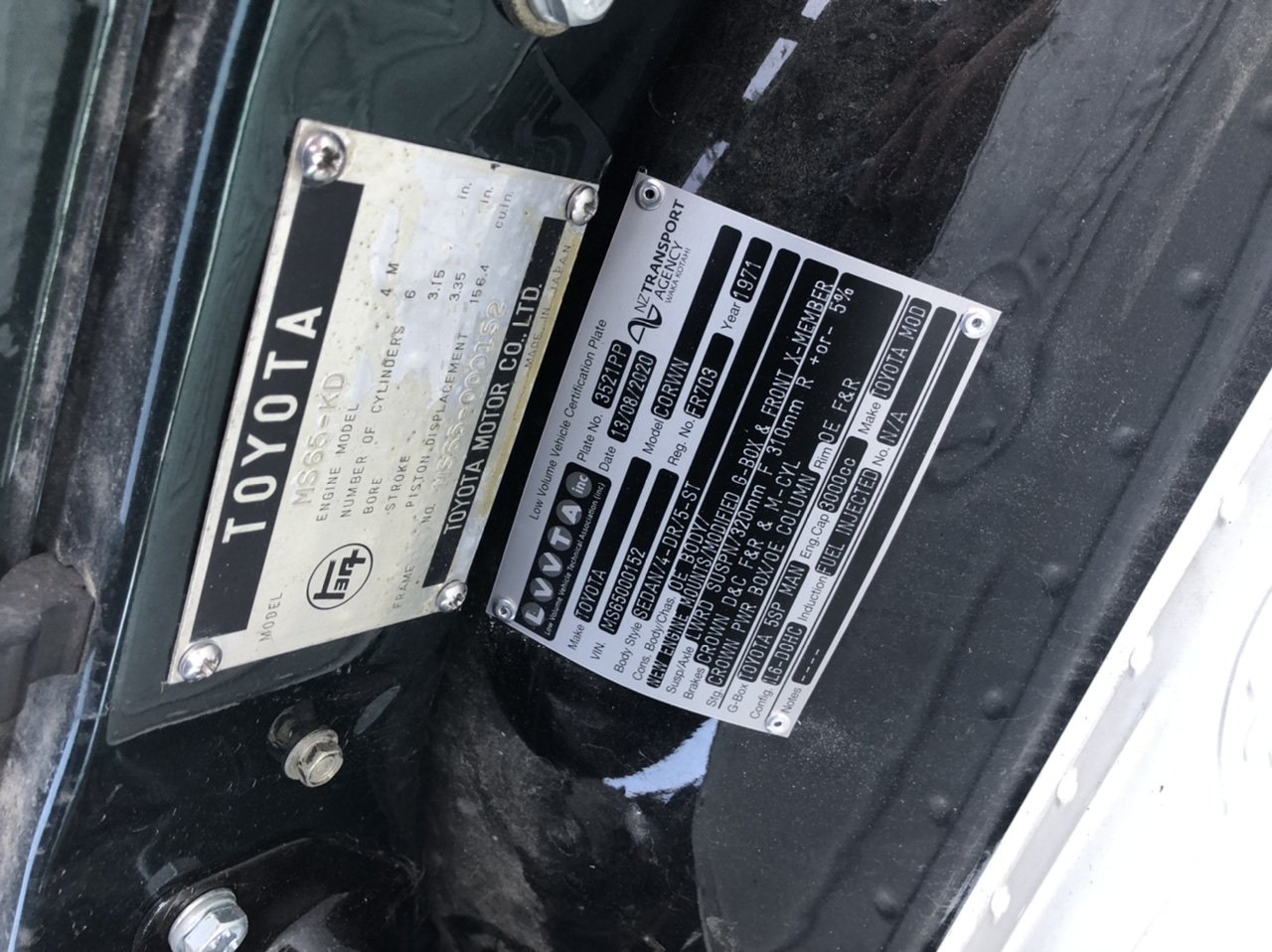

After 6 years of it being off the road its finally certed ,wof and reg . so stoked to have reached this point now its off to the dyno then i can enjoy it

- 79 replies

-

- 24

-

-

-

KBS coatings do a black heat proof paint

-

- 79 replies

-

- 16

-