All Activity

- Past hour

-

Daves new school holden shambles. (Is this project oldschool yet?)

Muncie replied to Muncie's topic in Other Projects

On another note did some more tuning got the new version that can be tuned all the way past the moon out to about saturn! Behaving nicely had to do some bizarre shit to the timing but I've now got it not freaking out under boost. Turns out what I thought was degrees of timing was an adder/subtractor number what I was looking at was plausible for timing numbers but wasn't....... More you know. So now I know which way to alter things to get the timing output going where I want it.- 746 replies

-

- 1

-

-

Daves new school holden shambles. (Is this project oldschool yet?)

Muncie replied to Muncie's topic in Other Projects

Picked some scabs today as they were getting pretty worrying rust oozing out clearly some bad bad work in the past. About 5 mm of artisan applied schmoo! There's more cracking up further back but it's not open to the weather yet, plan will be dig out the bad stuff get some etch primer on and back fill and blow the sides of car the original colour again. Will sleep a bit better tonight knowing what was under the paint, was bugger all really but under bog it looked major.- 746 replies

-

- 1

-

-

I made some similar things to do the floor in my ute. I used a press, but some things i learned i made 2x square 19mm plywood, with the same size hole in each of them. With plenty of overlap for the panel (2 or 3 times the diam of the circle) and zinged self tapping wood screws all around the edge. This helped a lot to keep any wrinking of the surrounding flat to a minimum. Then i welded a few pieces of 10mm steel together and spun it in a drillpress and shaped it with a grinder to make the correct floor shape, i made this maybe 2mm smaller than the hole in the bucks as you will have a hole in it to do this, what you can then do is drill a hole dead centre in the sheet metal you are shaping. without a press, you can put another plate of 10mm steel on the other side of your wooden bucks and using a greased up bolt, ugaduga the two together. 1mmis steel will shape really well this way, and might save you some elbow with the hammer

- Today

-

thermostat out, fill with water and soda crystals let it run for a bit. OS approved i usually back flush thr radiator and heater while im at it

-

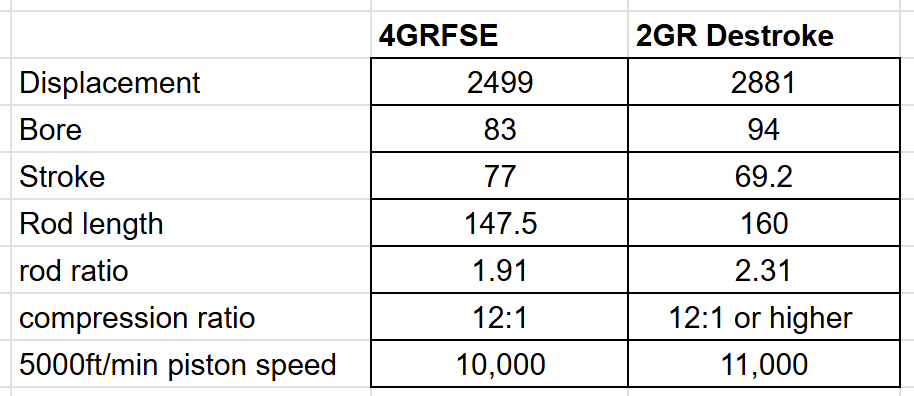

Ahh so yeah, I actually wanted something with as little skirt as possible, and the piston pin as high as possible. When your rod ratio number goes higher, there is less side loading on the bore so skirt isnt so important. If you have a 1.5 rod ratio, when your crank is at 90 degree position. The rod is pushing the piston on an 18 degree angle into the side of bore. If you have a 2.3 rod ratio, its only 12.2 degrees. @shrike Will just stick with normal 2MZ crank geometry for starters on that other motor I think. But I think there's some maximum oil shear speed or something like that. Which might mean that my big end or main bearing sizes are both too big for lots of rpm. Not sure yet. As per usual though its probably the crappy heads which will give up first.

-

When you dont have a press make a buck instead. Just trying some metal forming techniques for the replacement of the rusty bung holes and seems to be working out OK so far.

-

More thinking about cleaning it out that way but I'll push it outside and blast a hose through it

- Yesterday

-

Long coupla on my knees inside the boat just gone. I'm prepping to get the seat tops put in so am painting what is underneath the seats with three coats of epoxy before the primer and top coat. Havent actually figured out if I'll make them storage tanks or leave them as buoyancy tanks yet. I still have to cut an access hatch to help glue from inside as well as keep as an inspection hole for future. I have also been glassing the shit out of the outboard well. There is enough space now for a rise and fall bracket and I want it to be waterproof and strong. As I cut off quite a few strips of chop strand and woven I went around adding bits of tape around the mast and anywhere that took my fancy such as inside the stern where it all meets at a point. There is still more to do on the outboard well but the weather is so cold that it just isn't conducive to painting and glassing. Hopefully this rain fucks off soon and we can get a bit of sunshine.

-

Would you need custom bearings if you grind down the crank journals for more stroke? Actually now I think about it you only need oversized bearings when you grind it down if your using factory rods. So I guess if your making custom rods you'll add the extra length there.

-

So whilst I'm waiting for the cert man to give me the call off the bench I'm making it a little more finished. It's still noisy as shit so I'm doing my best to quieten it down a little. I am mostly deaf and have tinnitus so every bit helps.

-

You can pull the sensor out and put it into a cup of water thats been boiled by the kettle to confirm its reading as well

-

I can't comment on that stuff. But what I can say is that Cobra springs will custom make a spring to whatever specifications you want.

-

it still wont heat up lol my ute was never higher than just above bottom notch with a stuck open thermostat (except for the time i forgot to turn the fan on and had to open and close like 30 farm gates)

-

have you seen thr crf450 pistons? they are literally just ringlands with a boss for the little end

-

That is very over square. Is there anything with a longer skirt to help with wear? motorcycle pistons are commonly very short like that compared to automobile types. do you know how short it needs to be/shape required to clear?

-

It pays to shop around, can get some ok prices online it seems. Also keep your eyes open for people selling off from their stash, can get a deal then.

-

Chris' (in)practical daily and every expense spared musso

chris r replied to chris r's topic in Other Projects

So after hours of looking through parts catalogues the w210 gearbox appears to be the same internally as the earlier w126 box just with a different rear housing. The guy I got this gearbox off has another gearbox with speedo drive. Hopefully I'll be able to exchange it, if not no worries -

This is potentially a long way around a fairly small problem. I've been using my honda logo on the track a bit recently and have realized it has a lot of under steer. Rear sway bar helped but really need to stiffen the front springs. Current front springs are 3kg. Unfortunately I haven't been able to find a spring that has similar dimensions. Nor have I been able to find a similar style strut that would suit the current configuration. What I EXPERIMENTED with so far to try and resolve this, is a set of honda fit gd3 coilovers with 65mm ID spring. Spring rate options and heights are now endless. They have the standard two bolt at the bottom mounting so that requires the honda fit knuckles which are surprisingly close match to the logo. Using the fit ball joint pressed into the logo bottom arm the logo axle slides into the fit hub. (They use the same bearing so will press out fit hub and use logo hub instead) The problem I have now is the tie rod location is about 40mm lower. So my question is.... FIT ^^^ VS LOGO^^^^ Q. What are my legal options for spacing up tie rod ends? Any suggestions would be great. Even if it means a completely different path to get the same results. I understand i will need cert. Please note: Logo tie rod already mounts on top of existing knuckles so cant flip it over. Thanks.

-

lol true, the sensor is after the thermostat so would have read nothing haha didn't think about that. Maybe I should run without thermostat and see what happens. I did look into EFI stuff.. probably need about 5-7k to get it going. I'm willing to struggle more before that. The car isn't overheating.. that I know of. No steam coming out of the exhaust which might indicate head gasket, I haven't checked the oil so don't know if it's mush but also there wouldn't be water in there if there's no water in the engine so probably doesn't help. Haven't done compression test. True I think it's not pulling as much vac, I need to order a proper vac tester and try get idle working so I can confirm it

-

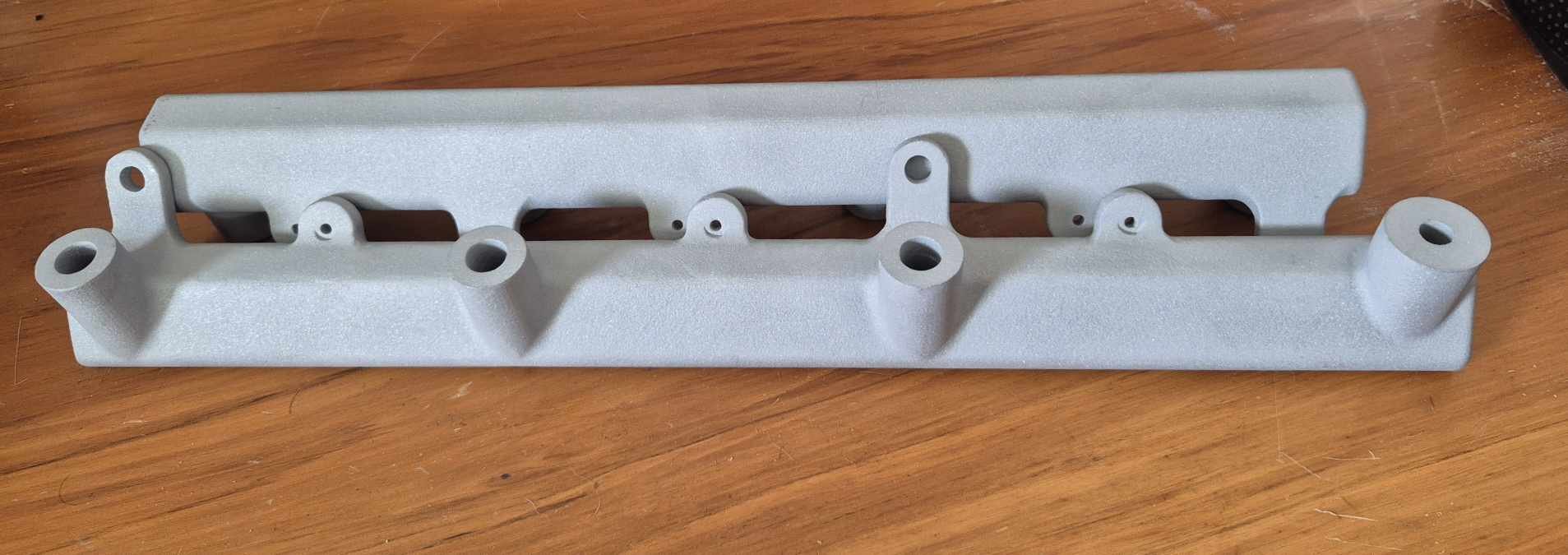

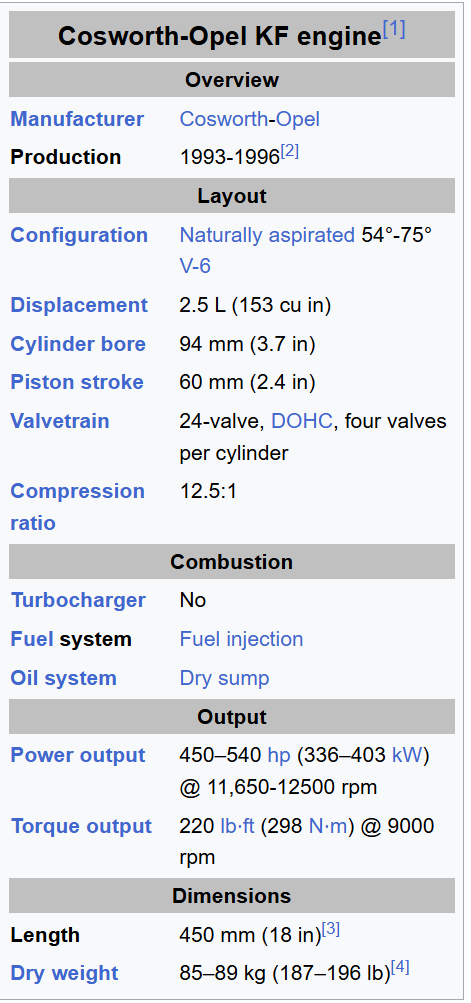

I got my throttle pulleys machined down to a smaller size, so they can open the throttles all of the way (Thanks Dad!) So this is all now working GREAT. and it's super snappy. So I started doing some tuning to try figure out the area just off idle, and why its such a bag of crap. I found that adding considerably more ignition timing helped a lot, and increasing injection timing to around 600deg (usually 400) However, at a fairly early stage I managed to blitz one of my ethrottle motors with about 100 amps too many haha. It still worked, but smelled funky. Well, it ended up crapping itself. So I've ordered another one but it's still a few weeks away which is annoying. Since I couldnt do anything else meaningful for that stuff, I figured probably a good idea to take all of the exhaust completely off and check it. I found a worst case scenario leak for my extractors on both sides. There were signs of a small leak coming from somewhere between the 3 pipes, up the middle of them. Blargh! Impossible to get to this to fix it without cutting everything up. I was fretting about it for longer than it actually took to fix. I cut off the collectors just slightly up past the 3x pipes. Then fully welded both halves, flattened it off, then welded back together. No more leaks and it solved what one of the ticking noises from the motor was. Even if these extractors eventually crack or something. I'm still absolutely stoked to have made these myself. My new fuel rails turned up, but I havent had them machined yet. But fits a lot better. Given the available space I think I'm gonna give up on having a front feed airbox. So thinking dual sides instead. I guess these could both rejoin around the front and grab some air from on top of the radiator. Or I could have air intakes behind the headlights, and go back to a full height radiator. Which probably isnt a bad plan. I cant fit the entire thing on my printer but I can do half at a time. So just banging one out to test fit. 2GRFSE Scheming "Since I am doing this, may as well do this" Since I need a custom rod for the 2GR destroke scheme. Has made me consider piston options. The factory piston is typical Toyota stuff, fairly big and chunky/strong. But for high rpm the lighter the better... No point in reinventing the wheel if something else already exists? I found a 94mm piston from a 400cc quad bike that runs 10k rpm from factory. Cheap and easily available, and nice and light! It has a 22mm pin so might even fit the 2GR rod (apart from that the rod is too short) So I've ordered one of these to test fit and see what sort of compression ratio will be achievable. A destroked 2GR doesnt end up tooooooo far off the geometry of the Opel Calibra DTM car which was absolutely hectic. I wonder if you could grind the journals down to lose another 9mm stroke out of it... Would only need 4.5mm taken off one side I think? Just to be 100% clear though, none of the above are detracting from getting the car onto the dyno ASAP! Once my ethrottle motor turns up, its ready to go. 2GR Destroke comparison for future scope creeping:

- 131 replies

-

- 15

-

-

Yeah I am thinking later on I will probably do an X pipe and 2x pipes to the back. All of the good sounding 2GR MR2s are X pipe and 2 pipes to the back. However, in the fairly immediate future I just need to consolidate what I'm doing and get the car to a drivable state. The current exhaust is good enough to get the car onto the dyno and so on. I'm keen to put down a baseline number, then put big cams in, then see how it's going. I've been very lucky that Stu has loaned me his tig setup over the last long while, but he needs it back to make some progress on his own projects. So no more exhaust stuff for now. So I'll be putting a tig setup into the budget at some point. Super 5000% glad that I persisted with it and can now weld alright. Invaluable skill.

-

And flat motors can benefit too as I have found out I figure its always going to be dependent on many other parts of the puzzle but if I was to muck about with another Mazda v6 I'd be doing two twins all the way to the back with an x pipe included into the sysytem. My Viva v6 merged just after the gearbox into a single all the way back and I now feel that cost it a lot of the nice V6 sound it could have had. Certainly muffled it down @Roman is there room for you to run two pipes back?

-

PALMY SWAPMEAT 2025: 1-3 AUGUST (20 Year Anniversary!!!)

Chris.QCR replied to Bistro's topic in Upcoming OS Events

Try @Flauski @sheepers -

Good point, I was thinking if no coolant was flowing then it wouldn't read accurately either. Ive driven engines short distance without coolant (didnt realise due to where the leak was) and had the guage not read correctly.

-

Daves new school holden shambles. (Is this project oldschool yet?)

zach_munce replied to Muncie's topic in Other Projects

Need to fix the monster truck ride height next- 746 replies

-

- 1

-