-

Posts

9,886 -

Joined

-

Last visited

-

Days Won

2

Content Type

Forums

Downloads

Events

Gallery

Everything posted by Testament

-

I dunno, more modern cars are actually made better in alot of ways, way better quality control in many cases. multi point fuel injection and electronic ignition have to be one of the best longevity things for vehicles ever. You put the key in and it works, it doesnt run rich or lean its just right always drives 300,000km and asks for more. yes interior plastics are prone to failing but some of that can be 3d printed and often alot more car were made of each model. and really thats still a probelm for older cars too. The skills needed to keep a more modern car running are a bit different, but I dont see it being that big of a barrier in the scheme of things thought. hardly difficult at all compared to some of the rust restorations that get taken on with old cars.

-

My fan/radiator sharn - stock copper rad and stock 1974 Fiat Magnetti Marelli electric fan > RX3 aftermarket radiator and spal fan mounted as a pusher fan in front of the radiator. so pretty much same story as everyone else, factory fans are was better than any normal aftermarket stuff ive seen. the depth constraint, is it all across the radiator or just in a few areas? some factory fans are only thick in the center where the motor is so if you can offset so the motor clears?

-

Good work, wholeheartedly approve pulling everything apart and putting it in boxes and piles in multiple locations to ensure forgetting where they go. I'm pretty sure you can make the bakery window without stripping it to a bare shell though so maybe the pies will still be warm when you get there. I don't know anything much about r32/gtr stuff other than the average owner now appears to be an Aussie drug dealer that goes through an engblock per drag event - and but check out kiwiCNC on Instagram guy in pukekohe that makes some hektick cnc gtr gearbox stuff. Probably justifyably hektikly expensive given how many hours probably go into them, but can be filed with the dct dreams.

-

^ whine and dine its the winning combination. a few belts and bearings is barely a minor inconvienience /this is the way

-

in nz I think there is a crowd in wellington, howard engineering? or something like that? maybe some others? but probably cheaper/easier to order from strange/moser/currie/etc in the usa as its their bread and butter for drag racing/hot rod/4x4 critters making custom stuff you need to have all the details, spilne type and count, bearing size and part number, all those hub and pcd dimensions. but you would need most of that anyway even if you are modifiying a factory hilux axle.

-

Why not just buy custom axles ? they aren't that expensive when you consider all this faffing we are discussing - none of that is cheap either. the benefits of bolting into what you already have, and having the right stud pattern, offsets, hub/disc centring dimensions is very attractive. and then they are new, not out of a 400,000+km hiluxace thats been burnouted over kerbs for 25 years

-

did noodles trump peaches?

-

it might, but throwing things on the ground is cathartic and also satisfies the lazyness quotient

-

mostly lazyness

-

Dropping them flat on the ground to rattle some the sulphur? off the plates just as hard as you can without busting the plastic case and spilling battery acid everywhere (who would guess that could happen) then putting them on a battery charger with pulse/maintenance mode/one of those^ things sometimes works

-

-

definitely plausible. check out nugget garage and cornfedboost on youtube, plus google performanceforums for v6 holden stuff its certainly doable. BA falcon with barra would be better? but in reality really better doesnt matter as long as it doses and skids to your satisfaction moo is still going to moo though also I would note you need to put as much thought into the gearbag/diff holding and putting down the power as the turbo stuff. autos can usually hold the power and put it down but may need some fettling of electronics or valvebody type stuff depending on the box.

-

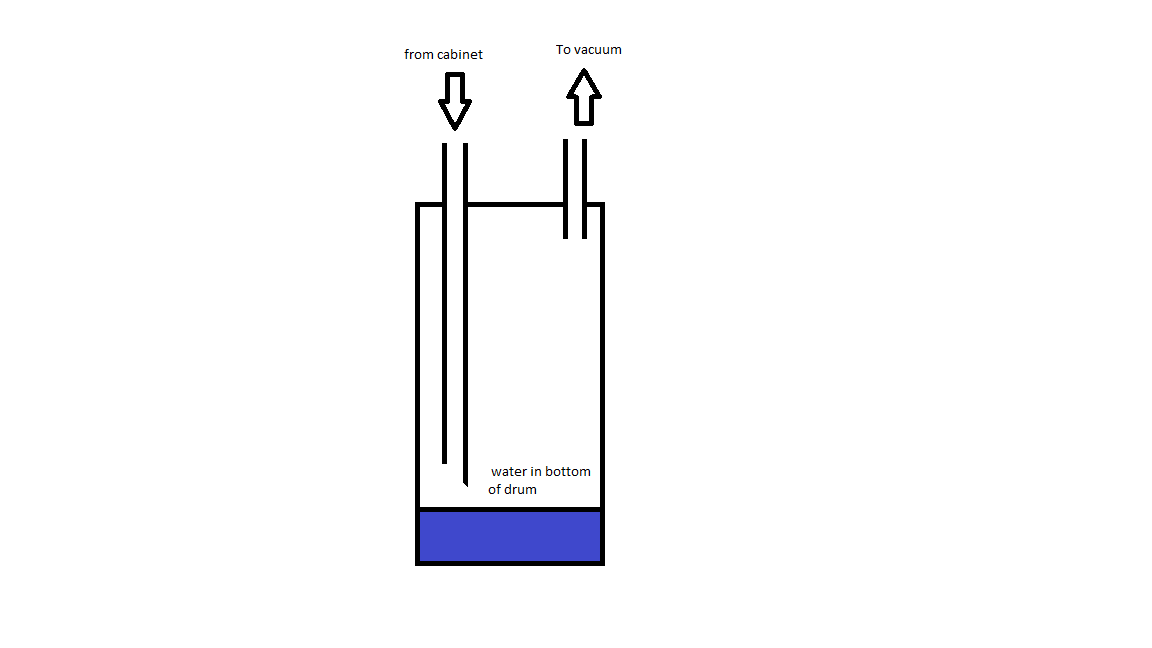

I use a drum with some water in the bottom as a pre filter, the inlet from the cabinet goes down almost to the water level with the idea being the dust gets caught in the water as it flies down into the vessel out of the inlet pipe. seems to work ok my free vacuum hasnt died yet and almost no dust comes out of the vacuum outlet which I pipe to outside.

-

Other solution would be to add more slam?

-

if the camaro was 8 inches lower it would comply? the way they have demonstrated it looks like they mean it applies to hot rods with exposed suspensions

-

valve sizes are the same yeah? so limiting factor = valve curtain area and valve seat diameter rather than port/chamber/etc.?

-

There's quite a few jeep aw4 (jeep version of an 340) manaul controllers around as well if the solenoids are similar setup? E.g. http://www.radesignsproducts.com/rail-controller.html

-

Nelson Area meets. Next meet TBC

Testament replied to sidewaysickness's topic in South Island Region

-

chain is ok usually too , a size you can get a 10mm or 12mm bolt through is going to be plenty strong usually. just make sure if you are bolting it on you have it so the bolt is not under a bending load. https://blog.uscargocontrol.com/working-load-limits-chain/ even noodle spec 6mm links are ok for ~500kg

-

shouldn't be lifting suspended loads over your, or anyone's elses head full stop no matter the gears rating. 99% of legit construction/industrial sites "never go below a suspended load" is a golden rule that shall not be broken. yes there may be some particular job specific exceptions, but you get the idea dont go under anything that might fall on your head if someone strapped it wrong or pushed the control knob the wrong way etc. - any of those exceptions have be accompanied with a specific plan as to why how/exactly what is being done and how that is being made safe and risk being minimised as far as reasonable practical. /safety rant m10 will also probably tell you than what they are selling is not for lifting but for towing or load binding. for lifting a normal car engine with a normal engine crane you can use whatever as long as you are certain its not going to fail - whats reasonable will depend if its a 90kg 1NZ or a 400kg 6BT. use as large a strap/chain as practical really. try not to put your foot under it etc. and try to get things balanced within reason.

- 20 replies

-

- 10

-

-

probably thought of all these things already but the usual things from industrial machinery issues bent output shaft whirling around damaging seal (seems unlikely with no vibes) undersize output shaft OD for seal (pretty unlikely with new from toyota but not impossible) tailhousing bush not aligned with output shaft inner bearing so shaft is not central to seal bore axial movement of shaft in operation resulting in wrong diameter bit of shaft running on seal any seal marks/wear on the shaft?

-

We usually use carboline paints or altex coatings on stuff at work when we need to ask for specific paints and have really good service/advice from their application people. TBH the last one I got some advice on I was very surprised, inside of an atmospheric flash tank, total ball of rust inside just painted it in hope to get it to last 4 more years/total band aid didnt have much else we could do at the time. opened it up last year (after 4 years in service) and 90+% of the paint was there. there had totally expected the steam and hot water to have just peeled it all off like it wasnt there.

-

read the rules for whatever sanctioning body you are going to be running under 5 times then read them again. there are many differences between manz/fia/nzdra/ihra/nhra/oranz etc. etc. etc. alot of the time you can actually build something compliant to several but you have to understand the rules. height of the aforementioned door bars, placement of backstays, relationship of main hoop to driver etc. can all be subtly different.