-

Posts

11652 -

Joined

-

Last visited

-

Days Won

2

Everything posted by flyingbrick

-

The only thing i tell people to change asap is the radiator. Those plastic tanks are a cunt.

-

Link to screen please!

-

Some Doug Thorley Sandrail headers. Sandrail? yeah weird right?! but they were $300 off trademe, brand new, ceramic coated, made in USA and RRP is approx $800 nzd before freight so if anything they are an investment. Seriously though- perfect for a forward facing turbo setup (and they look fuckin sweet which is really all that matters when the bits are just gonna be hanging on the wall) Feel like im back on track now- My previous LS attempt failed dismally as the LS1 had severe rust pitting in the bores. Buying stuff has given me much needed enthusiasm for actually physically going out there and doing stuff on it. I even took some metal to Bad Penny and had a bead rolled (needed for my floor)

- 137 replies

-

- 12

-

-

-

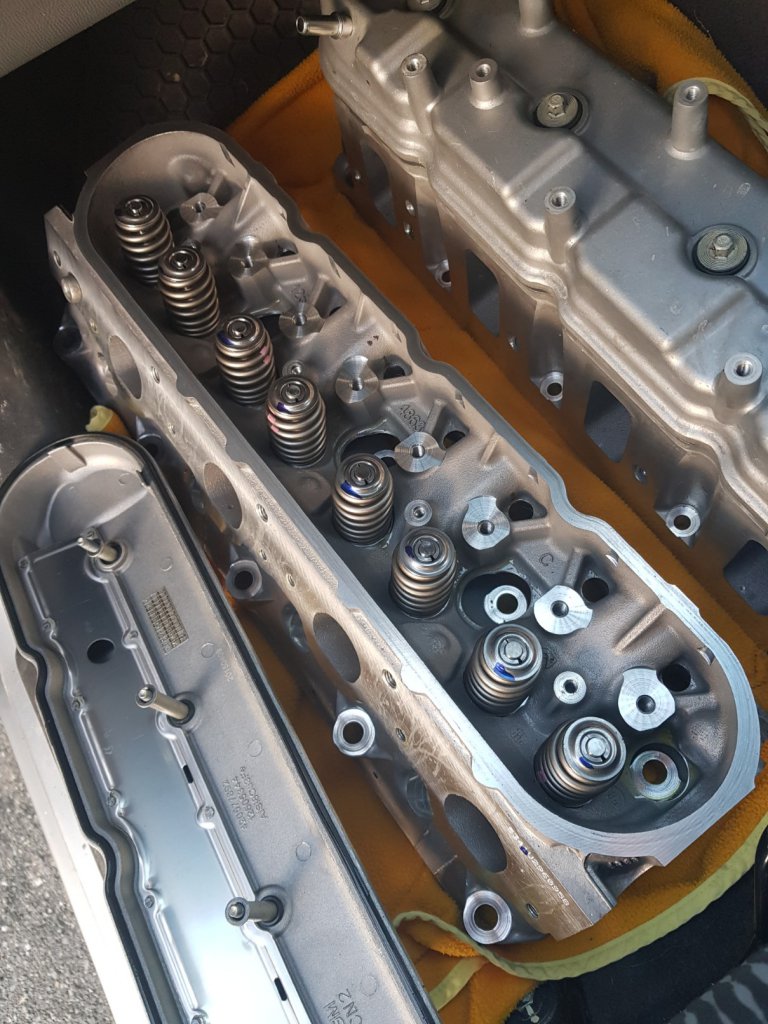

Wow, nothing here since July... zzzzzzz So I took more time away from buying stuff to focus on trying-to-have-a-baby stuff...Time to do something before 2017 is up. New LSA heads, im now looking for an lq4 block.

-

Waikato tiki tour Scooter/small motor bike

flyingbrick replied to 64valiant's topic in Upper North Island Region

HEY No need for that carry on- 148 replies

-

Waikato tiki tour Scooter/small motor bike

flyingbrick replied to 64valiant's topic in Upper North Island Region

I'll happily borrow anyones bike- 148 replies

-

- 1

-

-

Waikato tiki tour Scooter/small motor bike

flyingbrick replied to 64valiant's topic in Upper North Island Region

I've been on TM, added a few to watchlist. Might have to go for a drive to auk for a collection.- 148 replies

-

- 2

-

-

Waikato tiki tour Scooter/small motor bike

flyingbrick replied to 64valiant's topic in Upper North Island Region

damn I am actually seriously keen. Need to find a bike.- 148 replies

-

- 1

-

-

piazzanoob's 1964 ford Galaxie 500 seeedaan

flyingbrick replied to piazzanoob's topic in Project Discussion

Are we talking about the same vehicle? The big hilux looking thing? -

piazzanoob's 1964 ford Galaxie 500 seeedaan

flyingbrick replied to piazzanoob's topic in Project Discussion

Nice car! Is that a tundra ? -

chrisr's nixie and electronic barrying thread

flyingbrick replied to chris r's topic in Other Projects

Does the bar tube light up the whole length? -

chrisr's nixie and electronic barrying thread

flyingbrick replied to chris r's topic in Other Projects

ooooh, i thought it would have the tubes poking out the top of the box. -

chrisr's nixie and electronic barrying thread

flyingbrick replied to chris r's topic in Other Projects

hey man. looks awesome. I do think you should have the HV pcb sitting flat under the main PCB..looks hard to make safe where it is and its kinda out of place looking. -

Damn this is looking good, damn cozy! no need for bigger unless swinging cats is a hobby.

-

This is exactly why doing everything in writing is so great. Humans are good at making mistakes..

-

perfect, very cool!

-

get the cross out and use a slide hammer? (chain and a lump of steel) ?

-

Man that boat is beautiful. I LOVE the two photos of the old and new boats being pulled out. I have a thing where i compare photos to see whats changed- i find it fascinating. EG, looks like the same letterbox (its done well!) Also.. please explain how the truck trailer manages to pick the boat up and get it secured? I just cant work out how it does it!

-

Eastcapescapade November 24,25,26 - 2017

flyingbrick replied to johnnyfive's topic in Upper North Island Region

wot....lol Man that looked like epic fun -

Stay well away from sketchup. fusion 360 is brilliant.

-

yup! Get the right machine and you could do a one piece bellhousing and gearbox (better as you can then zero on the center of the input) or even stand a dummy engine block on the bed and go to the center of the crank/bearing jounals. Can do all sorts of cool stuff when ya think outside the box a little Also good if you have a large scanner is either scanning in the components flat face OR scanning in a template/imprint of the part- then importing this image into CAD and scaling it to a known measurement (can even include a ruler in the scanned image to get the correct scale) You'd be amazed how accurate you can get things like this. No doubt manually marking out would be great though! just make sure that you aim for 100% accuracy every step of the way as theres quite a few steps to making an adaptor and a little variation at each step could have you out relatively far at the end. EG, use a drillpress, make sure its bed is square to the head, use punched centers and then pilot holes with new drillbits Edit: @ajg193 I missed the bit about the school laser cutter. Probably better doing it by hand LOL

-

@yoeddynz that step-by-step was awesome ajg193 accuracy of the laser is absolutely not an issue- as an example that is slightly the same but different- our waterjet/laser guy can get holes down to .05mm tolerance. Hurmeez if you go with CAD a good idea is to get test plates cut from very thin material (1.2 would be perfect). The material is cheap and cutting is very quick so its not that expensive and you can test that everything is PERFECT. You can also leave the center of the test adaptor in place but have a perfectly sized hole cut out to check alignment with your input shaft etc etc. Also, I have used trustworthy milling machines with digital readouts for finding hole locations. You can place whatever item on the bed, clamp it down, put your 0,0 point anywhere you want and record the x y positions for each hole to get their relative positions and then put those numbers into your CAD program.

-

2 Trailer Loads of Death... Mostly Gyro X build thread

flyingbrick replied to Raizer's topic in Other Projects

I just had that same thought- so much better than the wheelbarrow wheels.

.jpg.11f91ef409ebc6735be7e3a484e3be76.jpg)