-

Posts

14,719 -

Joined

-

Last visited

-

Days Won

10

Content Type

Forums

Downloads

Events

Gallery

Everything posted by Raizer

-

-

Can anyone see any cert issue with swapping out Merc "Airmatic" suspension for a set of these? Rev9 brand. There is BC options too, either look to be a lot better quality than the D2 or YellowSpeed options. Would have to run lower rear control arms from a slightly different model Merc (C211 arms into my C219) and leave the height sensor linkages in place to keep the ECU happy.

-

VTNZ will recheck at any branch. Dunno about any others though.

-

Fibreglass worked for Mopar

-

Kimjon's next money pit - BMW Airhead cafe racer build

Raizer replied to Kimjon's topic in Two Wheels

-

Gargoyle Grease CN Medium is recommended where surrounding conditions are dirty and dusty. Applied cold by means of a paddle, it maintains an adhesive, tacky coating on the gear teeth. When contaminated with dirt or dust, it does not form hard deposits that may pack the clearance spaces at the roots of the gear teeth. The dirt laden grease squeezes from between the roots of the teeth, carrying away the grit and leaving the metal coated with a thin tacky film of lubricant That's from an oil gear information book I found, probably not much help in narrowing down exactly what it equates to in modern terms. /I've used motorcycle chain lube spray on exposed lathe change gears with good results, they just fling oil everywhere ha

-

Pics aren't showing in your last couple posts, google isn't an image host for hot-linking.

-

I'm down in Gisborne, but try to get to Auckland fairly often lol That's what I'm starting with, pretty solid just a bit rough around the edges, but the parts one is already paying off with a lot of small bits mines missing etc.

-

Will double check both utes tomorrow, but I think I'll have a good pair of hinges to spare from the parts one It didn't come with a grill or any of the front lights besides the headlights, mines got a pretty much new clear drivers corner light and this mess on the left

-

Still digging your B2000/it's inspo for mine ha! You wouldn't happen to have any prefacelift front end parts left over would you? I'm in need of a lh corner light, mine has turned to dust. Oh and I'm guessing your sorted for extra-cab parts? I picked up a parts ute today and have no use for anything that doesn't fit a single cab.

-

Sweet, will look into Belltech/other options I think. Just the package price for CT spindles, blocks, balljoints and shocks etc was rather tempting haha. But I'm too lazy to do a @GuyWithAviators and swap out all the suspension for every WOF so want to be easily certable.

-

And coming via an Aussie eBay reseller I'm guessing it'd likely be even worse for me to attempt to get proof too. Was actually your B2000 that's got me looking at possibly running drop spindles, I've recently picked up a 90 B2000 I'm wanting to tidy up a bit and drop a fair bit.

-

On the subject of Chassis Tech, any feedback on their drop spindles?

-

Eastcapescapade #6 2022 November 11th, 12th, 13th

Raizer replied to johnnyfive's topic in Upper North Island Region

That's this one, Otoko hill -

If you ever need to change the belt, rather than pulling everything out just cut it, pretty much anywhere that deals with conveyer belts will be able to supply a joiner. I had one in my old lathe, you just get a slight clink noise when it passes over the pulleys lol

-

Yeap fan switch or temp sender in some models.

-

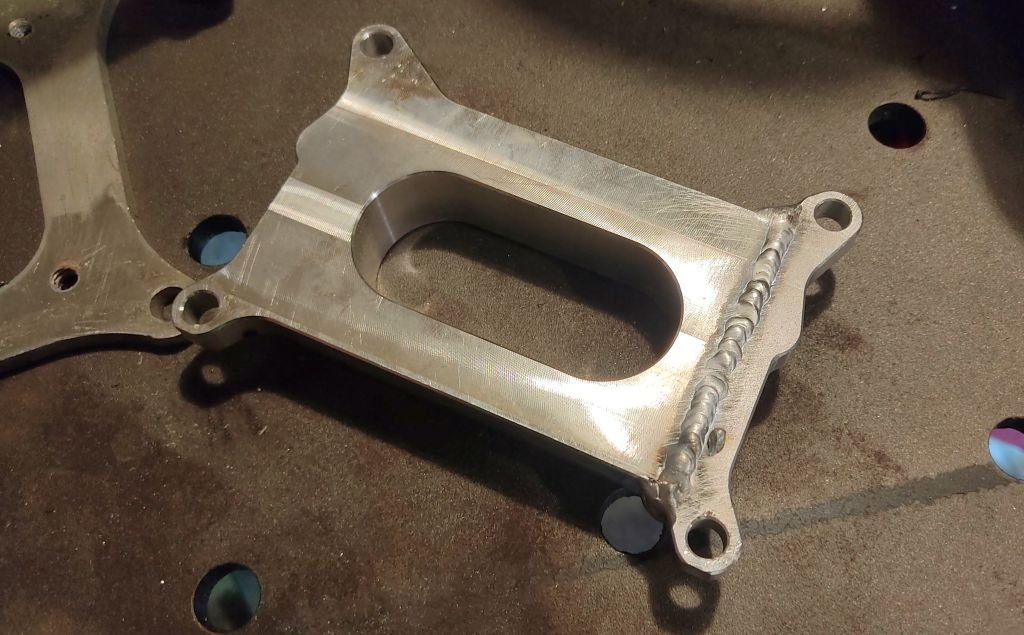

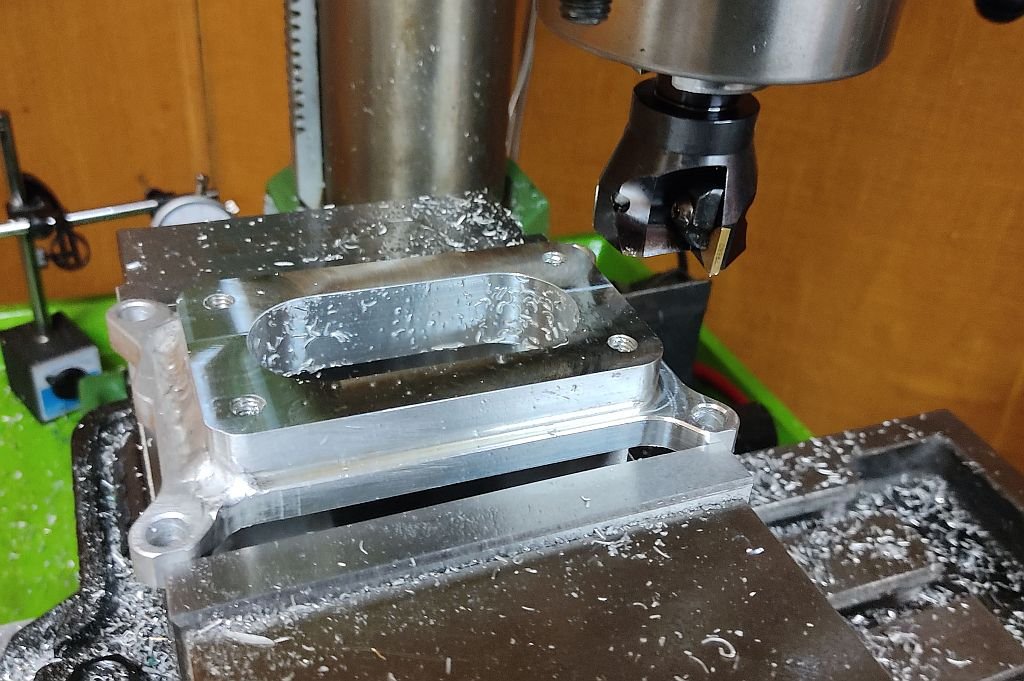

Even less pretty, but still hopefully functional. TBI to Holley adapter made from a couple scrap bits of 12mm alloy plate.

- 201 replies

-

- 10

-

-

Front radiator conversion, have to let the hot air out somewhere etc.

-

@chris r had a fancy Weber adapter CNC machined, but somewhere along the way it gained an extra 10mm in the base. So I made it a lot less fancy but a lot more functional. I haven't welded alloy in way too long/needed to preheat more, but it's solid!

-

No Bunnings near you? /or did you get a discount on D-plan?

-

Need to pull the little hose off the front of the turbo for those.

-

4V Century V8 powered Dyna Camper Discussion

Raizer replied to HumberSS's topic in Project Discussion

-

$5200 inc DHL shipping from AliExpress haha

-

Never had that mentioned, your mileage may vary though. /All my rear buckles are attached to the seats, but I've still got at least some of the rear belts.

-

Should do. I've taken my factory 8 seater Hiace through with 2, 4 and 5 seats fitted and it's never been an issue at all. Even taken it back for a recheck the day after inspection with 2 less and it was never mentioned.