-

Posts

14,719 -

Joined

-

Last visited

-

Days Won

10

Content Type

Forums

Downloads

Events

Gallery

Everything posted by Raizer

-

https://a.aliexpress.com/_mOoSo6B There's hundreds on there though, just search tungsten grinder.

-

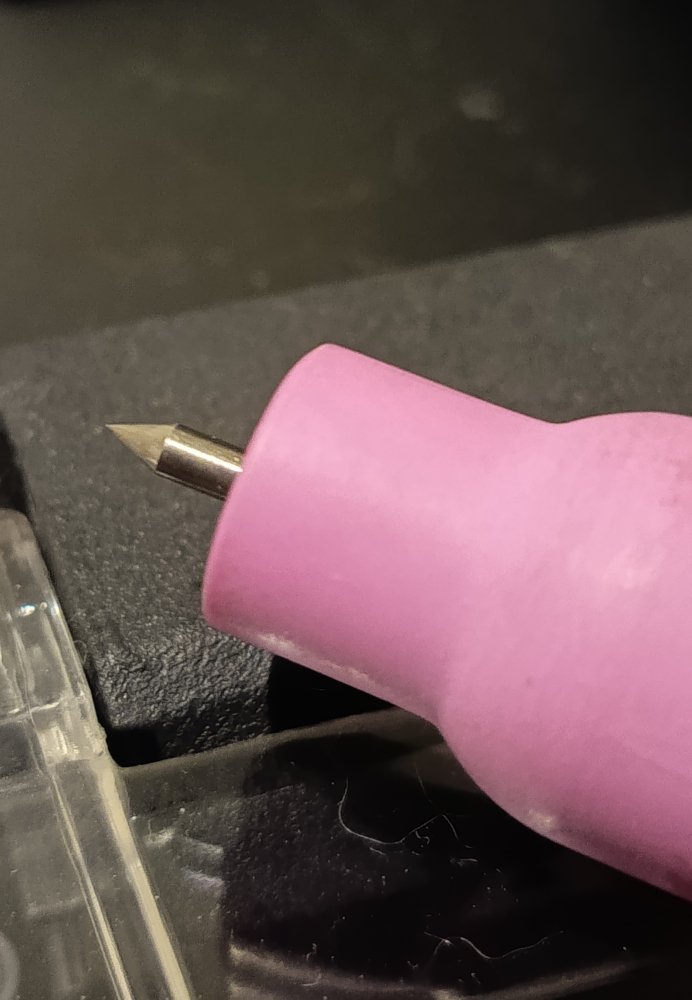

Picked up an AliExpress tungsten grinder Dremel attachment cheap, I'm rather impressed with it! Been using a silica carbide green wheel on my bench grinder for years, that's getting swapped out for a SS wire wheel now as I won't be going back to sharpening tungsten on it in any hurry!

-

That's a good point, had just been coming across plain 6061 in large round bar in the quick look I had last night. But yeah T6511 would be likely easy enough to get hold of.

-

On the gearbox side the adaptor can be located with the centre and also can have 3 small dowels around the bolt holes (either m8 or m12 depending on what engine the box was fitted behind) 4x m8 bolts to mount the uni flange, with slip fit locating recess. I offered to make one, 6061 would be much easier on my old lathe, pretty sure I'd be able to send it out and get it treated to T6 spec, but steel would be an option, just slow going.

-

Somewhat related, if that 6061 spacer/adaptor is acceptable would it need to be heat treated to T6?

-

Ooh is that what the blower is for? Water meth might be a good idea.

-

-

Or if you need longer, 2m for $4.50 at PBTech https://www.pbtech.co.nz/product/ITPCAP407/Dynamix-C-POWERCR-10A-3-Pin-Plug-to-Right-Angled-I

-

Oh yeah and about the settings, just from 15 minutes playing around with it last night (no welding, was in the lounge lol) the menus are very simple and pretty self explanatory to use.

-

I really wanted that one tbh, but I was already pushing well over my budget and my BOC AC/DC tig is still buzzing away perfectly etc, just wish it had conventual balance settings rather than the Everlast style and a memory function! Need to move the 160a on now, good little panel and light fab machine etc.

-

I'd been umming and ahhing about getting one of those Xcel-Arc 180 migs from SCA too since I keep needing a bit more grunt than my Raptor 160 has, I missed out on the last 25% off sale (thought it was all weekend, not just Friday night and Saturday), then they put the prices up. Was looking around for the best deal on one and ended up splurging a bit more $ than I really wanted to and got this today. Peach approved. Anyone want a 160A mig? Hardly used, works perfect etc (Old pic, too cold to go to shed to take any right now ha) Has most of a 5kg roll of .9 in it and will chuck in some new tips etc. Can bring it north fairly soon too.

-

Daves new school holden shambles. (Is this project oldschool yet?)

Raizer replied to Muncie's topic in Other Projects

Hope you like a bit of drifting, especially in the wet haha /Had 275/30r19 Laufens on the back of my first Merc, would spin them right up into 5th gear with ESP doing all it could to keep the car going straight.- 747 replies

-

- 6

-

-

-

Chris' (in)practical daily and every expense spared musso

Raizer replied to chris r's topic in Other Projects

Pulse your foot so cylinder 1 takes full advantage of the heavy springs and gets higher RPM than the other 4 cylinders 😆 -

Chris' (in)practical daily and every expense spared musso

Raizer replied to chris r's topic in Other Projects

It looked a little wobbly in the videos you sent me too. -

I picked up a BOC Raptor 40c a few weeks back, I know the Raptor range is meant to be shit (ask any BOC store about the amount of dead or faulty welders returned, I returned a buggy AC/DC tig within a week, but my 160a mig has been flawless for ages), but for $650 with 2 year warranty it's worth the gamble for me. Edit: nevermind, they've gotten rid of the clearance pricing and put them back up to almost $1100.

-

Weldplus down there are listed as having the Coregas E bottles, would be worth pricing them at least. Up here they are way cheaper than BOC and it's the same deal as at Bunnings etc where you just pay a one off bond rather than renting the cylinder.

-

Chris' (in)practical daily and every expense spared musso

Raizer replied to chris r's topic in Other Projects

It's telling you to pull it's head off and fix the valve! -

Yeah what model? I know for mine new hubs are cheap on Rock Auto.

-

Chris' (in)practical daily and every expense spared musso

Raizer replied to chris r's topic in Other Projects

We're both lucky the old owner of my car was so pedantic, cause of those couple light blemishes you got a great deal on CLS wheels and I got the immaculate set with the facelift centres on my car! -

Chris' (in)practical daily and every expense spared musso

Raizer replied to chris r's topic in Other Projects

Exactly my thoughts too, was optimistic about it just being the lifter full of crap and not letting the valve fully close. It's interesting that on cold start the other night it seemed to run perfectly smooth for a little bit before it started missing and coughing. -

I'll confess I haven't actually read the latest novel. But X pipe, 2x small mufflers, side pipes, send it.

-

Chris' (in)practical daily and every expense spared musso

Raizer replied to chris r's topic in Other Projects

That was my suggestion too, also to try BNT but be prepared to spend ages comparing it etc. Or turn a pair of shells from aluminium and solid mount the thing ha -

Chris' (in)practical daily and every expense spared musso

Raizer replied to chris r's topic in Other Projects

Just write OM601 on it and call it good. -

Chris' (in)practical daily and every expense spared musso

Raizer replied to chris r's topic in Other Projects

Which would also explain the original "down on power" complaint from the old owner.