440bbm

Members-

Posts

1,628 -

Joined

-

Last visited

Everything posted by 440bbm

-

That is very over square. Is there anything with a longer skirt to help with wear? motorcycle pistons are commonly very short like that compared to automobile types. do you know how short it needs to be/shape required to clear?

-

No worries. regarding the gearbox comment, was more meaning it is actually a g54 not something else with a different ratio. If you are certain its correct, then all good. just that it doesnt seem that 'short' in the ratio.

-

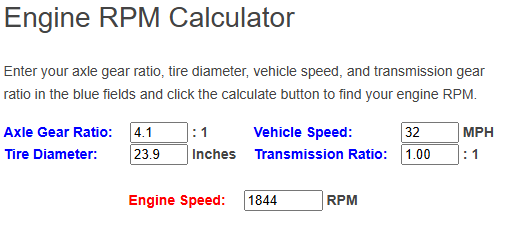

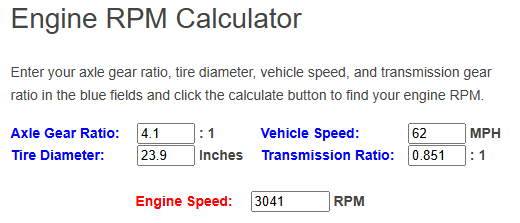

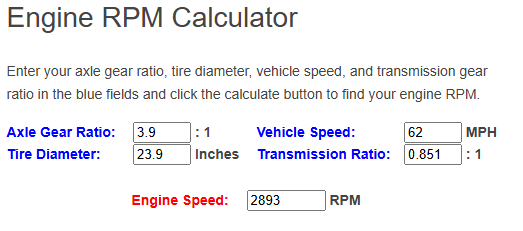

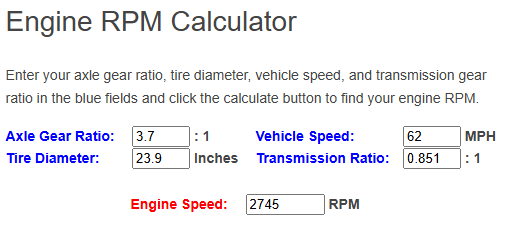

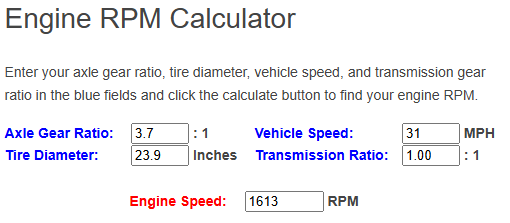

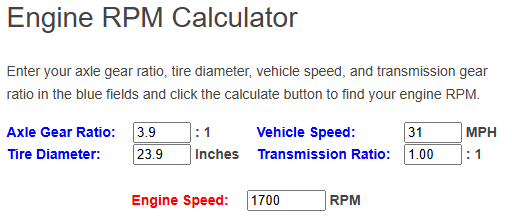

OK, sweet. Doesn't matter that you don't have an RPM counter, just makes it harder to verify the change to what you want with actual numbers. What gear do you use for around town at 50kms and obviously you're in 5th for 100. Here is your current setup. I have used 4th gear @ 50kph : 5th gear @100kph: So if we go to a 3.9 final drive ratio: 50 kph in 4th: 100kph in 5th: So if we go to 3.7 final drive ratio: 50 kph in 4th: 100kph in 5th: OK. There you can see the differences at nominal speeds. But what about 1st gear you say? I'm not going to do a @Roman spec graph for you which would be alot easier for your veiwing pleasure but the basics are this: 1st gear, 4.1 Final drive: 8kph = 1132 rpm 16kph = 2264 rpm 1st gear, 3.9 Final drive: 8kph = 1077 rpm 16kph =2154 rpm 1st gear, 3.7 Final drive: 8kph =1022 rpm 16kph =2043 rpm This would be easier, if I did an RPM to kph speed for you to see easier but because I'm lazy and cbf starting again, you can think about this the long way around it. But as it seems: 1st gear @ 20/21kph is the roughly similar revs at 100 kph with 4.1 ratio (2943 rpm ) 1st gear @ 20/21kph is 2800rpm with 3.9 ratio 1st gear @ 20/21kph is 2656rpm with 3.7 ratio Alot of funny numbers there. What I would do at this point, would be a cheap shitty RPM gauge that you can put in temporarily to see whats what. I question that you may be feeling like the revs are higher than you think which is not uncommon when you're sitting on top of the motor, not behind a firewall and alot further forward ( quieter ). The average becomes around 150 RPM in any gear in 0.2 change of final drive ratio. This also doesn't allow for wanting to change gears at different speeds with those without knowing what your RPM is in any gear/speed. Feels like dropping to a 3.9 may not be enough, but someone with more experience with your motor may be able to answer is the 3.7 going to make the motor suffer from torque. I'm almost about to question are yoou sure the gearbox is correct as the numbers don't look scary bad. TL;Dr - Not that certain I have actually answered anything or helped.

-

Bugger about the fail! not a huge difference in rpms between 4.3 to 4.1 and the same from 4.1 to 3.9 What is your gearbox, and tyre sizes? there are a few online calculators we can run to show you the change. it may only be 150 RPM, but that might be enough to bring first gear back into effect. what rpm are you doing at 50ks and 100ks? So we can let you see the difference. gut feeling is a 3.7 would probably be far more suited to your requirements.

-

It used to be, as was straight t6. But it has been a few years since i'd been involved with it now. Be interesting to see where the market is at now.

-

Why not just buy T6 or is it not available anymore? is T651 OK or not acceptable for LVVTA either?

-

yeah man they are quirky. this was the first model, the yfm200 but was actually a 225 grew up around all these quads, was a great time to be alive seeing the changes each year and riding through them all. yours looks tidy for its age! someones done some work to it, and the seats been changed so it was obviously well used and loved. They do go everywhere, largely due to the huge rear tyres and they suprisingly do well in the swamps too

-

what a bunch of stink cunts

-

but to be fair, that ute wouldnt pull a maggot off a chop anyway. so safe as houses.

-

yah, crayyyyyyyy. i staaaaaay tf away from them. not like lt400 / cof's have to be engineered mount directly to the chassis or gtfo but therre are alot of tow bars that are pinch bolted to the boot floor pan between 4 big washers in tin can cars. so up to you if it meets your requirements LOL

-

the tow ball/hitch thing was the killer for us. the rest wasnt hard, just time and bit of materials to re locate and modify things. depends on what you have the ability to do. they are also quite heavy, so if u dont have a hoist/ forklift / couple engine lifters and a few dude available for a few goes... it gets infinantely harder.

-

its a fair amount of work to do cos nothing bolts up but the main point the deck overhangs the tow bar hitch, so unless you want to make a custom one... also the rear wheel arch/mudguard flaps are in wrong place, as is the fuel filler mount point and a bunch of shit. light wiring too short. mounts are all the wrong height and location. we ended up just getting the correctly sized double cab flat deck as it turned out to be waaaaaaay more work than the owner wanted.

-

For me at home use, not that important. But when it comes time to shelling out the pingas once i have a shed built and power to use it, will be looking @ the marketplace to see whats available 2nd hand. but lol's was going to run this one past you when it got closer to see what u thought of it. don't have to now LOL

-

yah, it did seem somewhat user friendly ish. also, just remember its only like 15 or 20 presets total. not per page/ welding type too

-

Yeah, thats awesome looking machine. Thats the slightly smaller DC based machine that i was eyeballing @ field days. i was looking at the multi 230 ac/dc as i want to get a tig for the new shed. theres little price difference between a stand alone tig and this machine. means i could probably sell my 250 mig which is also xcel arc and just have 1 machine not two cluttering up a corner. sounds pretty fucking great. my only concern is it does have alot of features, and while sounds amazing for a learner to jump on and go great quickly with a little understanding - looks actually quite complicated for basic bitches like me. RAZORWELD™ MULTI 230 AC/DC MIG/TIG/STICK WELDER | Xcel-Arc® Welding Supplies

-

shit that makes life real easy! good score on finding that

-

not the additional + - for manual mode you can feel or is that part electronic

-

0.8mm may be a little bit big for panel steel if you arent too careful. you could try a 0.6mm for better results but you can tune it down and get the job done unless there is heaps to do

-

get an AGM for cheaper than lipo but all the CCA and max distance between runs. depends if racecar or not.

-

Richy's Mid Life Crisis, Season 2, Episode 8 "But I Digress..."

440bbm replied to Snoozin's topic in Two Wheels

Fair enough. Cannot say I blame you as it is pretty taxing and a part of it sucks the fun from the main ride itself which is the whole point. Glad that you are enjoying it and gotten over the slump! -

Richy's Mid Life Crisis, Season 2, Episode 8 "But I Digress..."

440bbm replied to Snoozin's topic in Two Wheels

Surely, we are due another story by now?! -

That's repairable if you can't find a replacement? machine through and push a new stepped insert through it.

-

beaten by mrjstar about target rev range comment.