-

Posts

1,261 -

Joined

-

Days Won

1

Everything posted by piazzanoob

-

+1 for Ben at A/C shop was involved in a couple jobs where he did the install work of the A/C system as a retro fit on classic cars and knew his shit and also stocks vintage air and all other related A/C parts

-

I did it once in a honda odyssey at waikaraka park. did the jalopy race going hard in the van and it stopped going on the last lap... didnt quite get to roll over the line and it ended up being i snapped the camshaft right by the spocket. not one dent and was sad i didnt make the derby haha so if i did it again would bother doing the jalopy race

-

Help!: Pickup some wood trim - Flat Bush - AKL

piazzanoob replied to Goat's topic in Upper North Island Region

Sweet once I know an exact date heading that way will shoot you a message. As heading onto the other island via boat -

Help!: Pickup some wood trim - Flat Bush - AKL

piazzanoob replied to Goat's topic in Upper North Island Region

I can assist with getting closer to you if you can wait till November or December. Could do next month if it worked out also -

With the oil pressure thing. my guess is not with the Ryco z9 filter used them plenty as common yankie v8 filter and definitely haven’t had that when priming oil pressure before starting. As was done before a start on a fresh motor. not something like running the pickup too high or not enough oil to maintain that pressure? could also be something like pump spring has lost its tension as guessing not a new one? im also not sure if I would want to run a new motor knowing that could be a issue even worse if it gets lower after longer periods of engine running

-

is the regulator you talking about an external bosch one? re55 part number?

-

Mr.mk1's Mopar or No Car '70 Dodge Coronet

piazzanoob replied to RUNAMUCK's topic in Project Discussion

What Clint Said is what it needs. wide open throttle on carb should be wide open on the trans linkage. Sometimes easier with 2 people one underneath moving the lever and one checking at the top. and as others have said only real adjustment is the bands and kick down. But would only adjust the bands if confident in doing it. Otherwise normally 727s & 904s as quite smooth during gear changes. also check throttle travel too as with aftermarket carbs they need playing with and the amount of throw on carb can be wrong. Also how is the motor running? As you were asking about timing -

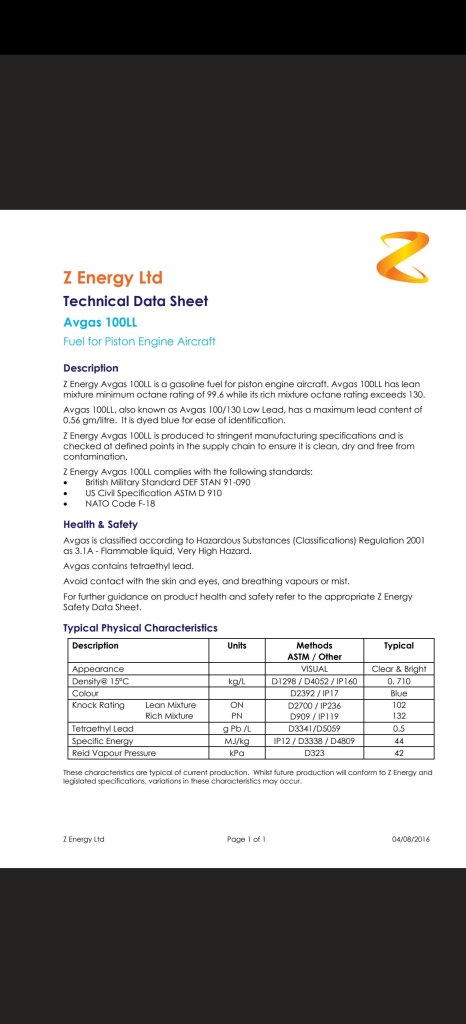

Ah right thanks Seen that avgas in rich form can get 130+ octane rating but nut sure if that is true or not

-

Anyone on her had much to do with avgas? Looking to do some testing with it on a 2stroke motor to try get more power. How easy is it to get and where is the easiest place to get it? Cheers

-

Rotormotors' 1990 FC Rx7 Brapta$tical coupe

piazzanoob replied to rotormotor's topic in Project Discussion

If your looking at doing some upgrades on the gearbox to help it last then i would look at getting the gears and shafts super finished. from what i know it was invented by NASA and is used on items under high stress. many racecars and bikes get it done on engine gearbox and diff parts. standard practice on high end racecar stuff. but gets done often now for things that get pushed to their limits. im not sure if anyone local to you does it but there is a crowd in auckland that does it. Morgan engineering in penrose. i have personally not had it done but seen the results of it done. -

K-Trips 1982 Holden Commodore VH Discussion

piazzanoob replied to KKtrips's topic in Project Discussion

That’s a good oil to use as definitely want a high zinc oil in it. as with lifter noise if it’s bad I would run it without the valve cover on the side that seems noisy and place a piece of cardboard to stop it splashing on the headers. Then use a hammer handle while it’s running and apply pressure to each rocker on pushrod side and find the one that goes quite. Or just get a long screwdriver and place your ear on it to find the noise. also hate to say it but comp cams haven’t got the best lifter reputation out there. I personally wouldn’t use them and would only use Johnson lifters myself. It’s a big issue with v8s and lifters. Not just comp cam ones either im guessing they were all stripped and cleaned prior to installing? As really want to catch the issue with the noise before it wipes a camlope off. although if the preload is currently zero then that would definitely cause a noise. How was the preload when you checked it? ive always set all that up before the inlet manifold is fitted and can see the lifter preloads. Then remove and fit inlet. Im guessing you already know all of the information I just wrote but if not here ya go goodluck as never is fun doing the job twice or having to lean in the engine bay. -

K-Trips 1982 Holden Commodore VH Discussion

piazzanoob replied to KKtrips's topic in Project Discussion

What engine oil are you using? also what brand lifters did you use? new carpet colour I think looks good too -

I did find this https://www.hawksmotorsports.com/82-92-camaro-firebird-dash-harness-used-select-application/ as im guessing your dash loom is cut up. otherwise might have to ring around some of the wreckers here or find a facebook iroc page and post. and im not sure also if an 89 loom will be the same or not. the engine bay as looking as if doesn't have any factory stuff anymore like engine related i would just start again and possibly just buy a rewire starter kit as has the wiring and colours and fuses and relays already. I think there is a few auto sparky type people on here

-

I kinda have a soft spot for these too. just not with the smog 305s or 350s they come with. sweet project seem like it needs much to get on the road?

-

Before putting some coolant in the motor do some kms first as with a new headgasket needs time to get some heat cycles in. putting coolant in now can cause a coolant leak from the head gasket. coolant is really good at finding somewhere to leak. i would do about 500kms before putting some coolant in. totally fine to do system flushes though with water

-

K-Trips 1982 Holden Commodore VH Discussion

piazzanoob replied to KKtrips's topic in Project Discussion

https://www.edelbrock.com/chrome-steel-fuel-line-with-3-8-barbed-end-inlet-and-wothout-fuel-filter-8126.html Can add a pressure gauge into these too. im not sure if they do a 5/16 barbed end or not possibly just 3/8 but im guessing you ran 3/8 line anyway https://www.edelbrock.com/black-steel-fuel-line-filter-kit-fo-eps-carbs-81343.html https://www.staparts.co.nz/Search-For-Products?time=8.0074 if you wanted one that you can add a filter too. Im sure there is also other manufacturers of the same thing around also. comes down to how much you really want to spend ive had radiator shops clean fuel tanks for me in the past and can pressure test them also. last one i got done last year was 150 from a shop in auckland. yeah those filters are nice that you can see if fuel is there or clean. the injection filter will be good as is a much smaller micron filter than a carb one im not sure how much an anti return valve will help but would be interesting to know. if electric pump it probably doesn't matter to much either. bad thing is edelbrock carbs evaporate fuel much quicker than a holley. so can't see the valve helping as they vent from the bowls most vehicles that have had fuel issues when sitting i just fitted a small low pressure pump before the mechanical pump to prime the system. but they just need to be fitted low enough that they are at the bottom of the tank height as they are not designed to suck or last long working like that. me personally are a fan of a mechanical pump over electric as less likely to have problems. but when running big power and need more fuel that's a different story. -

K-Trips 1982 Holden Commodore VH Discussion

piazzanoob replied to KKtrips's topic in Project Discussion

goodshit on getting some progress and getting it closer to the finish. Im not sure if your aware but edelbrock make a fuel fitting from the carb to a 90 that comes out the front which softline goes straight on. or they do a fuel filter fitting end version too also if the fuel filter you have is the clear glass/plastic jobbie from speed shops ive seen them blow apart which isn't good and they are really restrictive. once you open them as from memory you can unscrew them and see how shit they are. Any car i worked on that was getting fuel or engine related work on would get them taken off and a steel one fitted. or the customer was told about those filters. not that im telling you how to build your own car. just some advice if you weren't already aware has a nice lope to it too -

piazzanoob's 1964 Ford Galaxie 500 seeeedaaan

piazzanoob replied to piazzanoob's topic in Projects and Build Ups

Also did the annual OS kumeu weekend. good weekend with plenty of walking pace cruising can confirm the cars traction control on grass with boot passengers doesn't work. perfect grasskhana automobile Better living everyone- 77 replies

-

- 17

-

-

piazzanoob's 1964 Ford Galaxie 500 seeeedaaan

piazzanoob replied to piazzanoob's topic in Projects and Build Ups

Did some miles and took to beach hop in November with zero issues t Then did some OS drags prep needed some other wheels/tyres for the day ended up buying some new tyres for my original wheels. also got a bonus of getting a white wall one too also managed to get my best bp this time round too. car ran flawless with zero issues too- 77 replies

-

- 10

-

-

piazzanoob's 1964 Ford Galaxie 500 seeeedaaan

piazzanoob replied to piazzanoob's topic in Projects and Build Ups

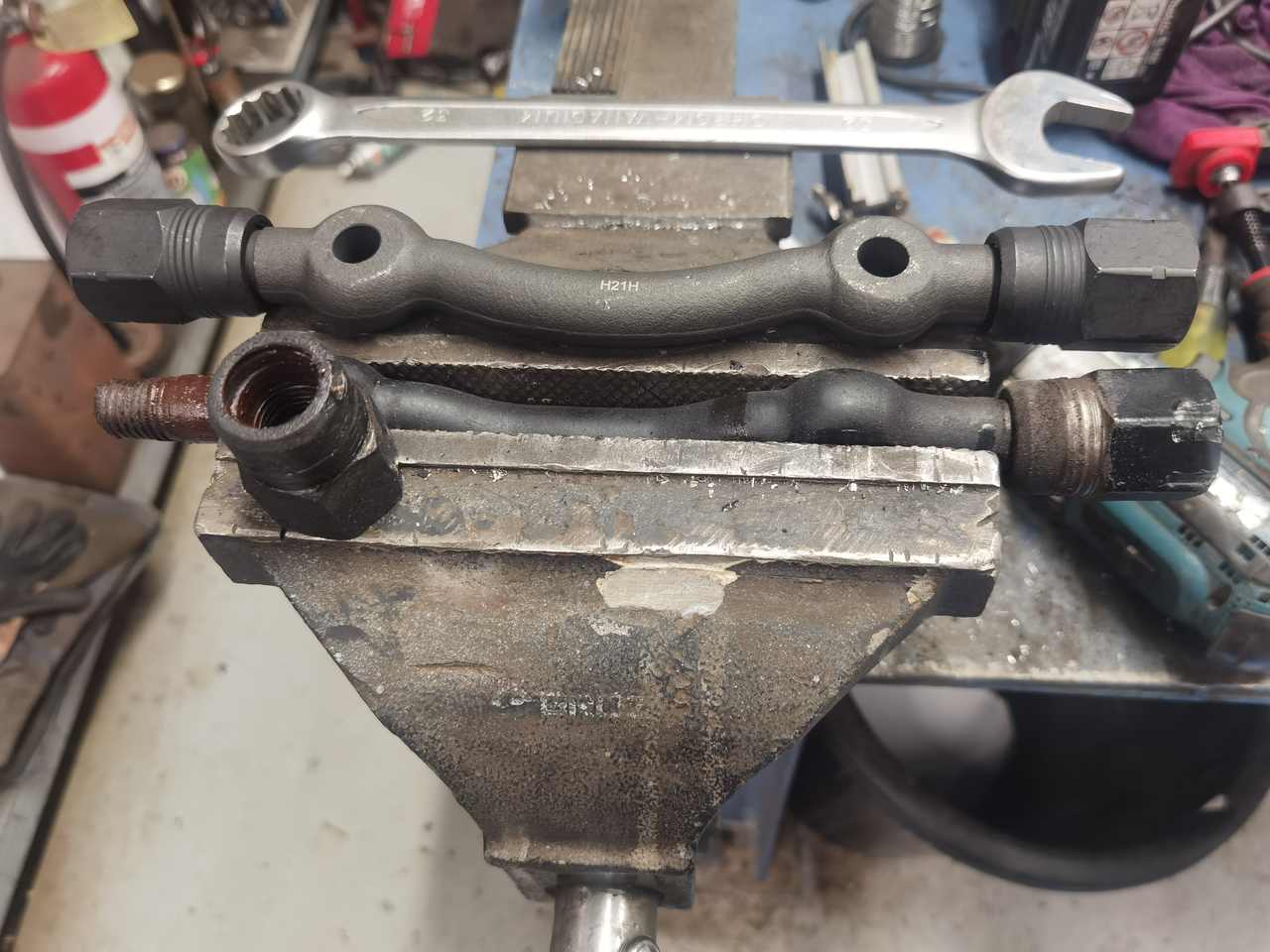

Another yearly update on this thing did a pre wof check on it myself and found some play in the front top inner arm bushes. so had to order the parts in from the USA since ive owned this car i always had thought it had a rubber bush for the top inner A arm bushes. but no they actually have a nut and thread and use grease to keep them quiet and not wearing out. my car never had any grease nipples in there to keep them lubricated. bit of a shit design really but that's what they came up with. pulled the arm off with a view of quality factory welding if you look close on the thread of the shaft that it has worn away the thread. old vs new ones fitted new ones to both sides and added grease nipples. now no play in the front suspension. also while i ordered the shaft kits i ordered some bits for the steering wheel. only had the part since 2019. needed the pieces to make it stay on the wheel. after the repairs the car got another clean sheet wof -

Head crack repair cast iron. Repairable or am I buggered.

piazzanoob replied to Muncie's topic in Tech Talk

I would be checking to see if the cracking continues below the valve seat insert which would required getting the head to a reconditioners and getting machined out then following by a crack test. repairing cracked heads isn't a common thing to do now most end up in the bin and find another non cracked one -

Either sterling clutch and brake or greenlane speedshop GSS

-

if looking for gauges on the lower budget side i would use. trisco mechanical water temp. super accurate and easy to fit. have fitted these to quite alot of vehicles even just for testing trisco electric or mechanical oil pressure gauge. if using mechanical gauge i wouldn't use the factory plastic line or a copper tube. have heard of the lines splitting and spraying oil in the engine bay and cabin which hot oil can catch fire. get some fittings and AN hose to suit. https://www.supercheapauto.co.nz/p/trisco-trisco-water-temperature-gauge-mechanical-52mm/293680.html?cgid=SCN01081906#start=3 https://www.supercheapauto.co.nz/p/trisco-trisco-oil-pressure-gauge-mechanical-52mm/293682.html?cgid=SCN01081906#start=5 https://www.repco.co.nz/en/globes-batteries-electrical/electrical-accessories/gauges/trisco-electric-oil-pressure-gauge-go520/p/A1027541 https://www.repco.co.nz/en/globes-batteries-electrical/electrical-accessories/gauges/trisco-electric-water-temperature-gauge-gt520/p/A1027994

_Easy-Resize_com.jpg.e1ab4158d1c3a9910f383f0359e7f962.jpg)

.jpg.120f29a0d28eae7e25bf6f66bcb6b0a2.jpg)

.jpg.6b2390fe6e1eff7140b591631aec95c4.jpg)

.jpg.53ff715ccf5f06f8cef68dd7f89399b6.jpg)