-

Posts

6,542 -

Joined

-

Last visited

-

Days Won

4

Content Type

Forums

Downloads

Events

Gallery

Everything posted by BlownCorona

-

the fuel pump might want a rewire of some sort or just a prime button fitted. its wired to only run when the engine is running which is good but if left to sit the fuel can evaporate in the carby and cause the hard starting. a priming push button would let you blast some fuel into the float bowl before starting. im sure there's a clever automatic solution available too if so inclined.

-

i think there was trepidation over the battery situation, too big and no real clamp means if it slid forward it would arc on the hood.

-

-

will be there around 12 also. if someone could pm me address that would be great. i have a decent selection of tools. post up if any jobs are gonna require something not already accounted for and ill see if i have it.

-

didnt that guy put four intercoolers on his car too? man its been years since i saw that disaster of a project. performance forums was it? home of the overnight gearbox door step delivery service. someone link the whole thread if youve saved it to bookmarks please. hilarious that you're dealing with him, condolences

-

years ago i put a 5" sackbarrow tire on a yamaha mint for a burnout and it last 4 seconds. you can get solid sackbarrow tires which i assume would last for ages, longer than your vertebrae anyway

-

do not ask me why, but this post stuck in my brain from the moment i saw it a decade ago. and i thought about it every time i saw a gto. Photobucked ruined the gag, but it was a photo of a gto doing a skid @glen (ugly comment wasnt related to gto i dont think)

-

im the other member mentioned. keen to help and can bring tools if needed also. i hope nothing changes for me plans wise, shouldnt do, as i really want to do this

-

Tech Spam thread - because 1/4" BSP gets 5 hand spans to the jiggawatt

BlownCorona replied to Roman's topic in Tech Talk

thats weird, last i heard he made it home to auckland fine but with some temp strangness but then at some point it did a headgasket and he had the original block sorted out and was putting it all back together. i helped him locate a head gasket ect. i wonder if it was for his other crown -

Truenotch's 1997 Toyota GranV - Francis Jellybean

BlownCorona replied to Truenotch's topic in Other Projects

a couple years ago dad was working for a place that did building maintenance and water blasting washdowns for all kinds of usually government or council property. he often went way out to the middle of nowhere with a waterblaster to wash a building and do any any repairs. most of the company had stupid modern pickups, but there was also a hiace supercustom 1kz 4wd (he personally owns a 1kz hiace 2wd and adores it) he wanted that, he then convinced them to install the heavy duty rear springs that he has fitted to his own van and then proceeded to have the most user friendly rig of the fleet. while others were carrying step ladders and rummaging around their dumb high side trays dad had all the space in the world. i kicked him a spare modern stereo head unit that i told the company they can keep if they let him fit it and he had music and comfort while he toured the back country towing probably 1500L of water and all his tools in the back with a clear 2nd row of seating for luggage storage/smoko room. Then people who had been with the company much longer tried to steal it from him but the owners were cool people and told them to jog since he had set it up himself and those people had turned their nose up at the old van in the corner.- 37 replies

-

- 12

-

-

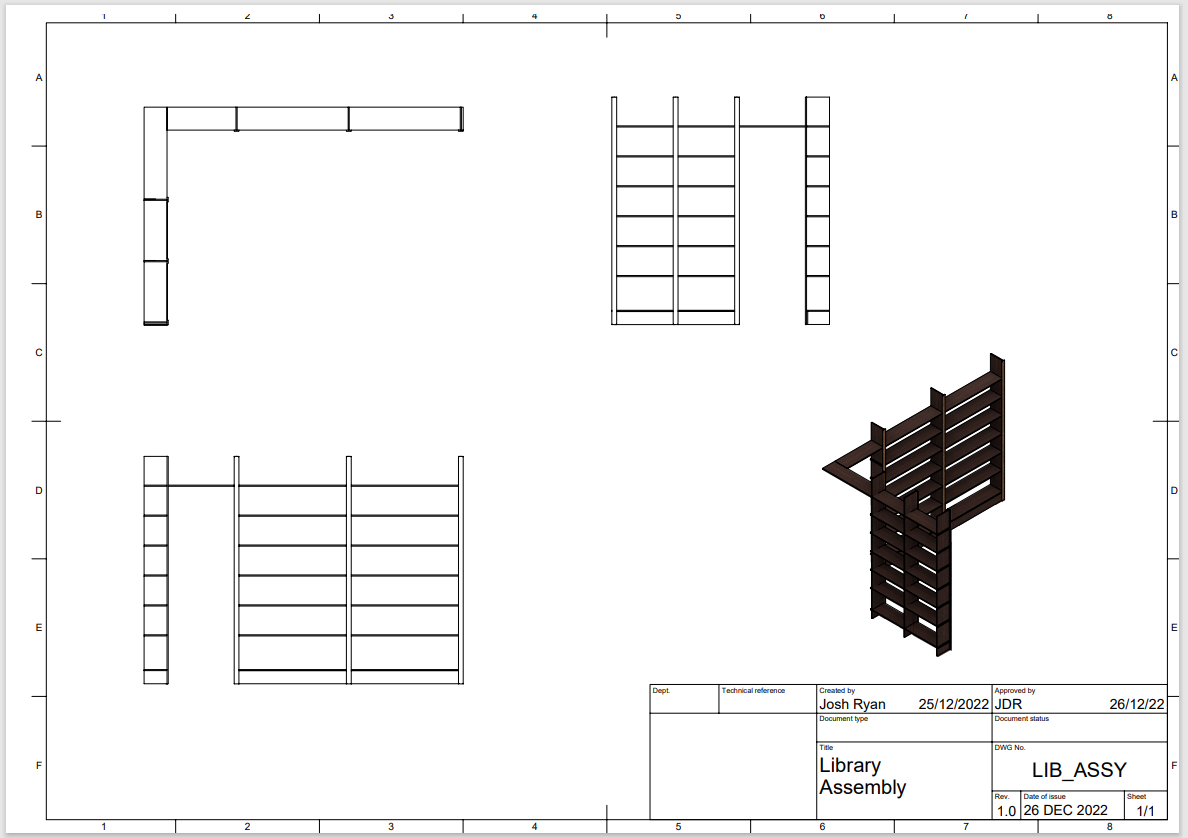

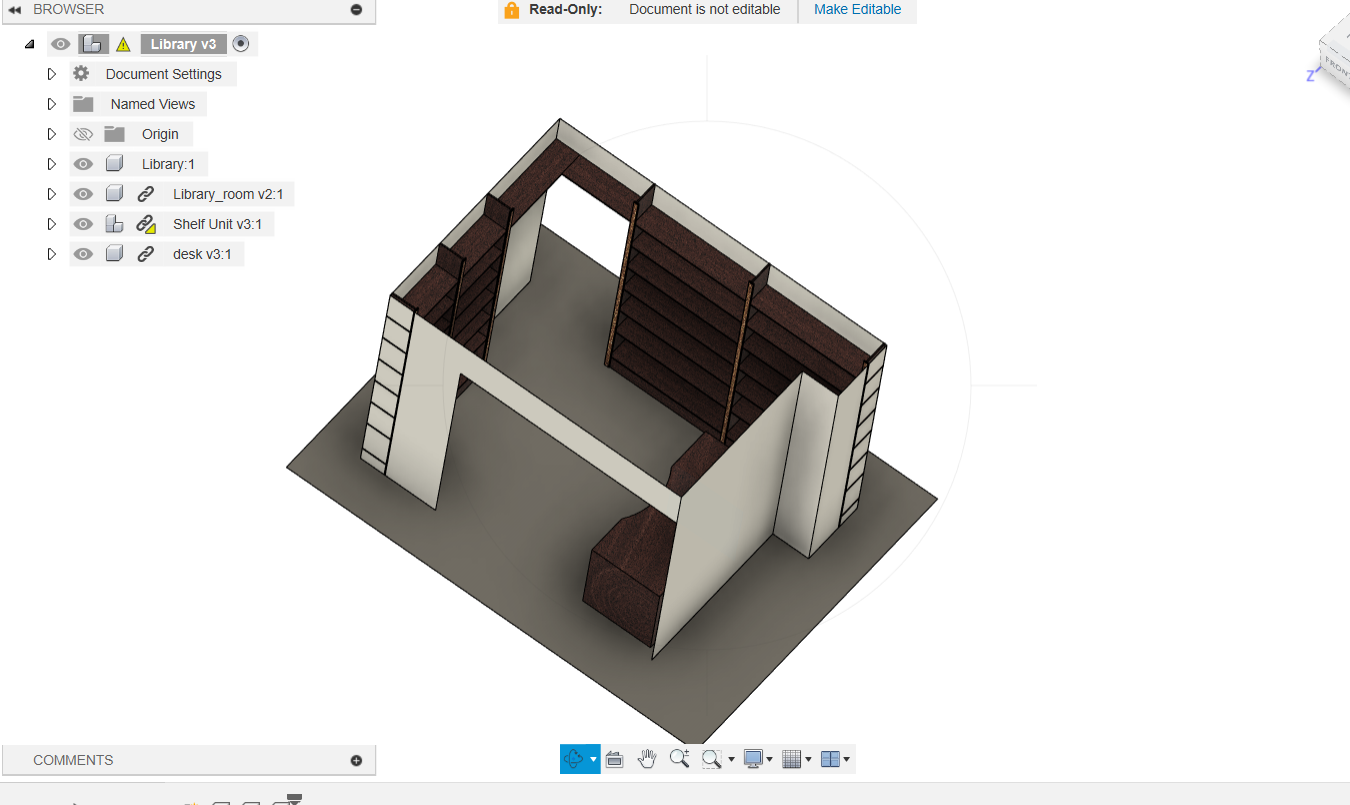

didnt even know it existed! i did all the arranging the old fashioned way. thats super cool and will be usefull for other jobs (on my little cnc where space really matters) you also make a good point, i did not achieve the above at home with a drill and a rusty saw, lucky for me, my workplace has a full woodworking bay and i made good use of the large table saw and router table.

-

vista print do them for office purposes. from memory their website even has the tool to convert an image into the line with various sliders to to get it right. https://www.vistaprint.co.nz/stationery/stamps/self-inking-stamps nearly made her cry for $15 i also played pretend engineer and designed the whole lot on fusion 360. i modeled the room dimensions and did it this way for two reasons. firstly to get a feel for spacings and to play with colours and secondly so that i could tweak dimensions to maximize the sheet usage. i ended up with a tiny amount of wastage which i turned into a pretty decent shoe rack.

-

Reminds me that a while ago I asked about having library shelves machined. Well I decided that I wanted to do it all by hand since I'd always told my wife I would build her a library (not assemble her one) It's kinda messy at the moment because she's part way through post grad studies and there are a bunch of new books that need filing which means moving every book lol The large framed cartoon was designed (and tattooed) by her tattoo artist to resemble her, I also turned it into a stamp. It's not quite finished, I need to decide on what I'm going to do with the shelf edges, and I'm on the hunt for a structurally sound but old wooden ladder to fit with a rail. I'm quite happy with how many husbands get in trouble when their wives see it. Makes for an excellent space whenever I get to work from home. The work office sucks, our library is quite possibly one of the nicest environments I've ever been in (when not in messy Xmas holidays mode)

-

are the oversize holes still central? could you have some stepped dowels made up?

-

Mr.mk1's Mopar or No Car '70 Dodge Coronet

BlownCorona replied to RUNAMUCK's topic in Project Discussion

its been a while since i was dealing with measuring HT leads. but from memory you cant simply measure their resistance, rather youd need to measure the 'Z' or Impedance which is a combination of resistance, capacitance and inductance- easier said than done. regardless, the old boy at Canterbury Auto Electric on waterloo has a masters or phD or similar thesis on spark plugs & leads and he/his team would be the man to both measure and make recommendations. -

"starting my own foundry" is about as far removed from abandoned project as you could get! Nice.

- 244 replies

-

- 13

-

-

-

-

DirtyThirtys 1984 Toyota Starlet KP61

BlownCorona replied to DirtyThirty's topic in Project Discussion

it looks like that spoiler was designed to have a thick rubber gasket under the leading edge? i bet it would look better with one. cut nice and flush to suit. -

good call, This is probably the most badass project on the site, keen for an update, or given the last few years, just confirmation it hasn't been abandoned!

-

i have a cube shifter on my w50 in the corona. it has a nylon (i think) bush. apparently they can transmit more transmission noise into the cabin, though i never found that. im assuming those with that issue have the above steel bush. on a related note. the cube shifter is awesome. looks like theve gone up in price, but i paid about $250 and am very happy.

-

BlownCoronas 1971 Toyota Corona

BlownCorona replied to BlownCorona's topic in Projects and Build Ups

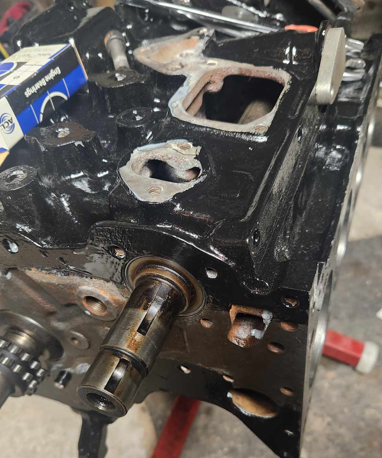

a bunch more progress on the engine build. mostly related to preparing the various parts i've collected and making them fit where they sometimes wern't meant to. First up, have the 20r pistons machined to accommodate the valves. ill find out this weekend if they are correct. The still need the fresh edges broken but i am very happy with the job done by Proturn Engineering here in Christchurch. Then i set about fitting the auxilary bearings, turned up a couple of press tools to pull them into place. took my time but went trouble free. Shaft dummy fitted and smooth as butter the crank too. Still need tidy up the edges on the painted parts. Then, now that the bottom end is all but ready, and i'm going to have the whole lot balanced, i needed to finally fit up the trigger wheel i made like 4 years ago. I parted off the unused front pulley and turned a spigot from its remains. with a matching cut on the trigger. once i look up if position is important ill tap mounting threads in the meat under the remaining pulley. Ill need to think about making a cam angle sensor because i want to run proper sequential fuel and ignition, i think ill just cut up a dizzy and make something nice and low profile. Getting close to actually assembling for good which is very exciting.- 140 replies

-

- 14

-

-

why does the AI call the the rotory corona a "Corona" does it no longer believe it is one?. the AI knows you put mazda parts in there matt, it knows what you did and it will not forget.

-

i just came back here to correct myself on that, yeah you would just tune around the change in flowrate with VE table. i guess its only important for boost pressure where you might actually stiffle the flow enough to run out of injector unless you ramp up the pressure to compensate.

-

in the same way that boost lowers the pressure differential, vacuum would increase it. so unless your ECU can compensate for this, a referenced FPR would be required?

-

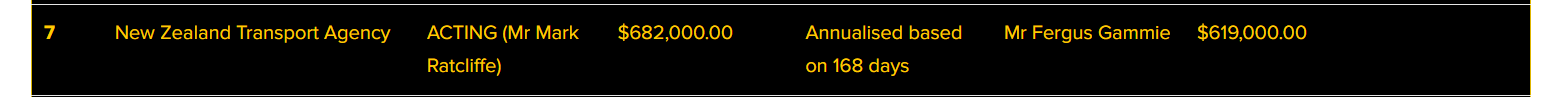

sounds like a monopoly. its a computer system, it simply does not cost that much to run. the exec team however needs to gets paid.. 2019 and 2018 ceo salary data.