-

Posts

11,673 -

Joined

-

Last visited

-

Days Won

2

Content Type

Forums

Downloads

Events

Gallery

Everything posted by flyingbrick

-

@Roman would be proud. PS, Oldschool needed its own foundry so good work.

-

I hope nobody ever reminds me about each of my projects

-

stretching the whole "all purpose" statement.

-

Hey, how's this going

-

Richy's Mid Life Crisis, Season 2, Episode 8 "But I Digress..."

flyingbrick replied to Snoozin's topic in Two Wheels

Thats a pretty decent upgrade! Did you manage to get both static and loaded sag set pretty good? -

3 generations of Muncies impulse bought the same GN125.....

flyingbrick replied to Muncie's topic in Two Wheels

what are you replacing it with? -

SR2’s 1947 Vauxhall “Rigamortice” Discussion thread.

flyingbrick replied to sr2's topic in Project Discussion

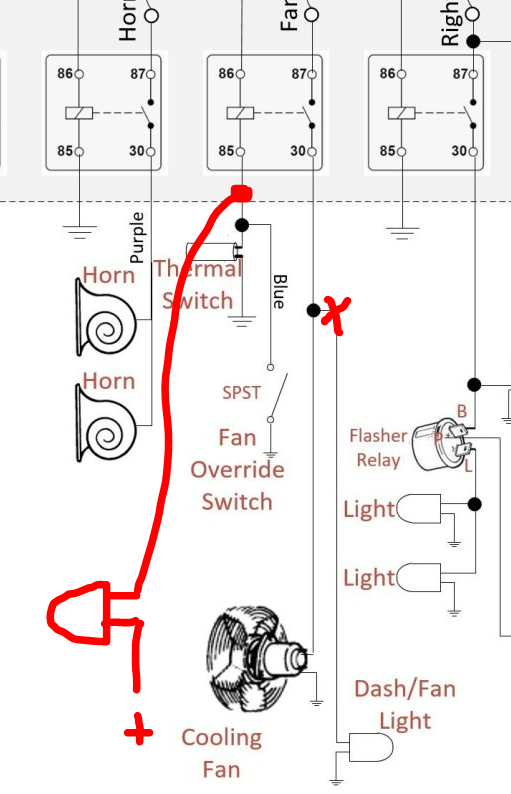

this hurt my head. Could you do this? Would mean its not affected by anything the fan does and the lamp is switched on by the thermo switch or bypass by giving it ground. -

You know someone with a lathe so maybe you could turn up a fitting to weld or bolt to the top of the sump to support that tube

-

one of those pressurized oil canister things would be perfect for this if there was ever a problem. that machining is beautiful!!! I wondered what taht yellow tape was for when you sent me the pics- I see now it was to ensure max vacuum. Soooo coooooool.

-

Hey man. Absolute pleasure being able to contribute something (the printing) to one of your projects- especially since you have provided so much inspiration over the years with your printer!

-

I mean, knipex is a brand isn't it? Do you mean is there a similar quality brand in general?

-

Umn, I'm a sicko but love the look of this with just the top fairing. Maybe a good compromise between full fairing and full naked? Also, this thing sounds fucking awesome. Video does not so it justice.

-

is there information missing from this post?

-

Loving your new dash idea! Does it allow for variable brightness? EG, bright enough to see during the day without illuminating the whole cabin at night time

-

There is no need for that You need to be comfortable moving the knobs around, It is perfectly normal. You should have a vague idea what kinda power to set it to (Guess), then its just a matter of fiddling with wire speed until you get it going nicely on a piece of scrap. if it gets worse- turn the knob the other direction. The single only thing that is going to make you a better welder and more comfortable is experimentation.

-

Settings change based on many variables.

-

-

I love it. had no idea there were so many of these around!

-

have just had new vehicle tracking installed on our vehicles. They have demanded that unit (which is like an old GPS style device) is mounted in the middle of the vehicle where it blocks visibility- there is a perfect spot for it on the RHS where this is completely alleviated. Management has said that its not been a WOF issue in the past and the centre location is fine- I have argued that it may be fine, but it could also be better- I have told the installer to move it and I'll cop any flak that comes my way - just stupid people making stupid decisions. So, I know you can get a ticket for having dangly shit hanging off your rear vision mirror- but could there possibly be wof concerns with having it in the middle as they want? I'm willing to go to war over this, cant stand rules that aren't logical. (the second image is what i want. The first image is what we are being told is our managements standard that must be adhered to)

-

Looks like you are sorted but years ago I build a guy a bead roller (fyi it was fuckin badass, huge laser cut side plates spaced apart with heavy steel spacers) He had me adapt it to work with a motor and gear reduction unit he found new on ebay which was for positioning either telescopes or satellite dishes (something that looks at the sky lol). Thought it was a cool solution.

-

nice clean new zinc coated sheet is soooo nice to work with and not that expensive

-

Wow man, looks great!

-

lol, thats quite funny. I had to have a smash on google maps to confirm

-

OK, broken housing ideas time. My vote is as follows. bolt housing into place with single remaining fastener. Take a pair of good vicegrips, use these over the housing flange and that tab of unbroken steel to clamp things together. Weld up the jaws of the vicegrips so that they cannot come lose. optional: if you'd like the repair to be more professional, once the jaws are welded solid you may use an angle grinder or gas axe to cut the rest of the vicegrips away so that only the clamped and welded jaws remain. Or, yeah i guess if you couldn't be bothered brazing up the thread and you don't have a welder then you could drill right down through a bit larger and use a longer bolt with a nut?