-

Posts

14,314 -

Joined

-

Last visited

-

Days Won

88

Content Type

Forums

Downloads

Events

Gallery

Everything posted by cletus

-

Front= theres a couple of things that would need to be done differently for cert, needs shocks, bottom arm welding would need tig& ndt Rear looks mostly ok but I wouldn't recommend a 2 link. With a 2 link, to have any side to side articulation something has to flex. Americans love doing 2 links in various things because they are easy, but virtually no OE manufacturers do them, the only one that i have come across that is common is 60s chev trucks but they have soft rubber bushes and the bars come in quite close together at the chassis end and the links can flex a bit cause they are a I beam shape. Some 4wd vehicles have a similar system (nissan patrol or safari, landcruisers etc ) but they all have big rubber bushes at the diff end for articulation Have a look at info sheet 05-2011 on the lvvta website, that has a lot of info about it

-

The guy there said $1950 +gst to blast, prime, and paint. Quite pricey but everyone I've asked says they do a good job, I could get it done for less than half the cost but I dont think it would be as good as I want it to be

-

Dropped off all the piping at HPC, ordered some stiffer shorter springs for the front, booked in at autoblast to get the undersides blasted and painted , and booked in at gt refinishers for engine bay paint. I pulled the engine out again so when the car is gone I can get things done on the sump

- 134 replies

-

- 14

-

-

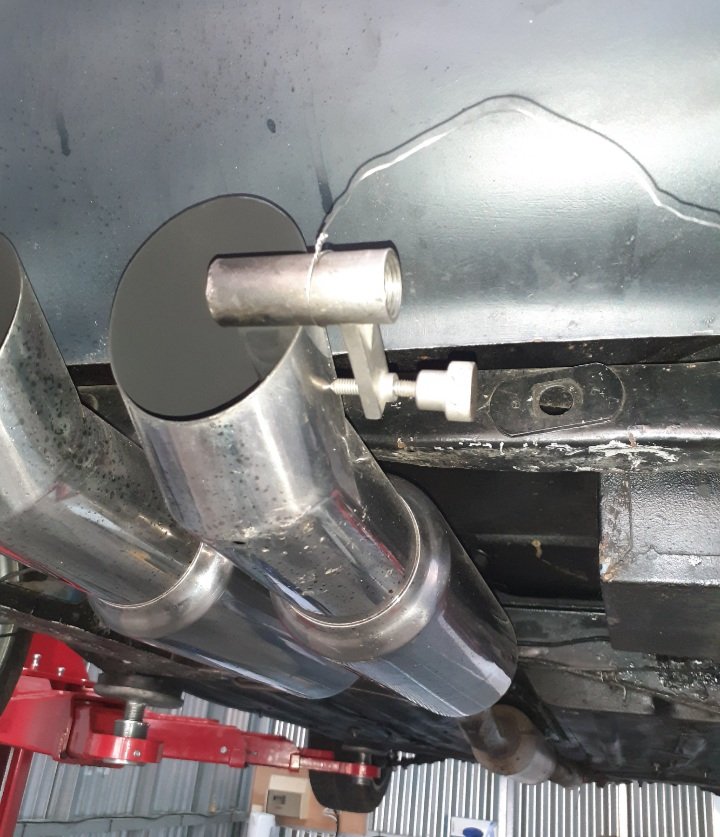

The wire is in case it falls out, the sensors do not enjoy bouncing along the road and are expensive to replace, this is something I learned the hard way

-

-

China tyres are probably better than BFG's anyway haha

-

Does it run the way it is? You could try it and see Most likely it will need to pass a 3 stop brake test, which is 3 stops from 100- 0kph, under 4.4 seconds each stop, in a total of 2 minutes max. I have not done a 620 with drums so I dunno how good they are. But commercials in general have brakes a bit bigger than passenger cars of the same era so it might be ok with good quality shoes and everything in good shape

-

- 94 replies

-

- 16

-

-

-

-

- eunos

- eunos roadster

- (and 6 more)

-

Wheels look good!

-

These arm bushes always seem to be flogged on them too. I drove a turbo one a few weeks ago, was pretty fun.

- 94 replies

-

- 3

-

-

- eunos

- eunos roadster

- (and 6 more)

-

It may also be an issue with the bottom balljoint assembly taper being a bit big, have seen some pretty average aftermarket ball joints for valiants It's not uncommon for aftermarket arms to come with washers or tapered spacers to correct taper issues. As long as the taper is the same and the nut doesnt bottom out on the end of the thread it should be ok

-

Welcome! I did a similar swap 14 years ago but I cant remember any specifics on wiring, other than it worked with the shifter position switch on the side of the trans not hooked up, but it did weird things when shifting manually. I wired the switch in and it was good after that. I used a generic aftermarket lever type shifter, a b&m unimatic I found www.lextreme.com handy when I did mine, i just had a look and it appears it still works

-

Baz 2440 Valiant slant6/Single side draft Delortto

cletus replied to Baz 2440's topic in Project Discussion

I dont think it would matter if its sized and jetted correctly, the carb doesnt care how many cylinders it is feeding, it just puts 'x' amount of fuel into the air that passes through it and the manifold delivers that mix to the cylinder -

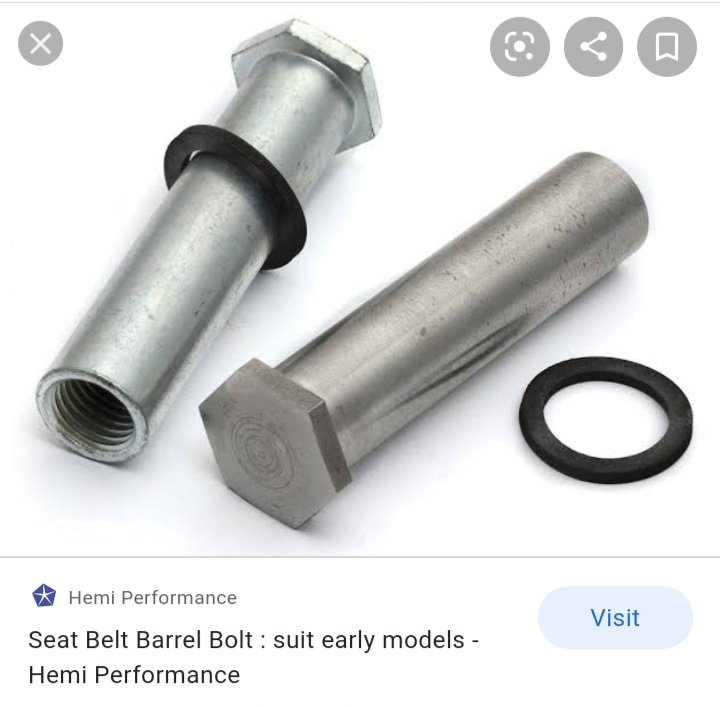

Try searching 'seat belt barrel bolt' This was common in 50s and 60s cars when lap and diagonal belts became a requirement

-

Rear lowers will be an issue if they have an adjuster on the inner bush end but it depends how far outboard the shock mount is, LVVTA does not allow any side loading on a threaded joint, sometimes if it is within the load rating of the joint we can pass it if we can do calculations to prove it's ok Fronts if its upper arms, have not done any hardrace altezza ones but the usual issue on that design of suspension is when the car is low enough to need camber arms = the upper ball joint hits the body before the bump stop limits the travel= the car has to be raised= then it doesnt need camber arms any more Also the adjustable arms are usually taller or longer or a different shape in the ball joint mount area so they make the problem worse than with the standard arms In general, hardrace stuff is ok, you do have to make sure the welding is good though as some is shit. The reseller here swears they are all welded by robot but I've seen a few where the robot forgot to turn the gas on, the robot missed the join, or the robot fucked up the weld, ground it down and had another go. Silly robots

-

What car is it?

-

A mount attached to the side of a chassis rail has to span the whole height of the rail So if your chassis is RHS you cant butt weld a flat plate to half way down the rail as it will cause cracks. So you could either make gussets that go full height of the rail, or weld a reinforcing plate on first which I'm picking is what you are talking about

-

Yetchh's "more problems than I expected" bay kombi

cletus replied to yetchh's topic in Project Discussion

You're a brave man Rust like that gives me the heebie jeebies -

Shame you need forward and reverse, otherwise a 5hp Briggs would be lol to power a lathe with

-

Sweet! How much tarmac vs gravel do you plan on riding?

-

Have a look at the modification threshold on lvvta.org.nz. that shows what you can do without cert It wouldn't be much though. Tyre size would be limited by no more than 5% greater overall diameter, offset rules limits how sticky outy the wheels can be, and lift would be limited by what springs you can fit in a factory shock and still have 40mm droop

-

Shuzz's " I've had this since before you were born" Hilux

cletus replied to CarolsHusband's topic in Other Projects

Yeah I dunno how he thinks hes going to get out of there without a light bar -

Nice car. Welcome to OS!