-

Posts

14,719 -

Joined

-

Last visited

-

Days Won

10

Everything posted by Raizer

-

Yeah fuse or breaker as close to the battery as practical, distro block to amps.

-

Got the hubs off the car? /Won't take fuck all to take .4mm off with a flapper though.

-

Random slightly cool stuff you built but not worth its own thread, thread

Raizer replied to h4nd's topic in Other Projects

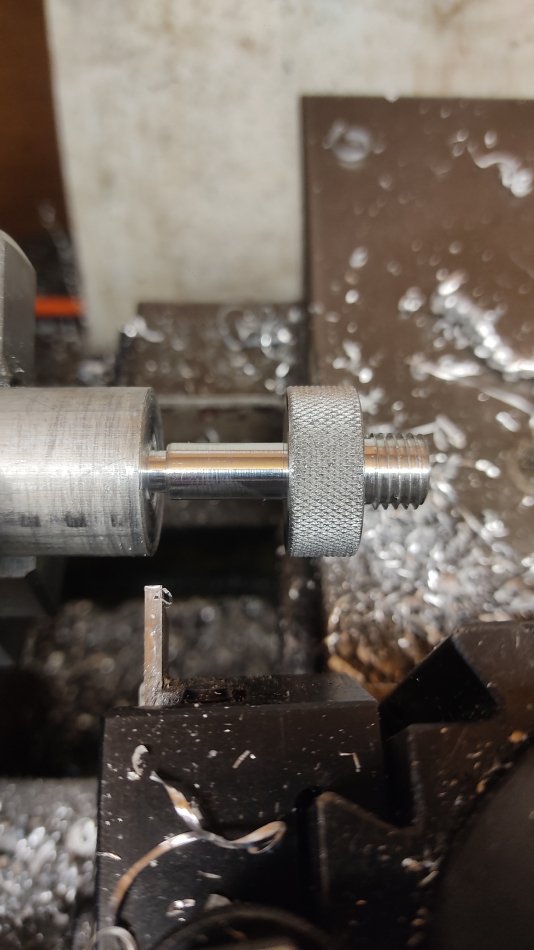

First time dealing with a transmission that's filled from the drain, don't want to pay hundreds for a proper fluid transfer pump etc. $20 Warehouse weed sprayer and 15 minutes on the lathe should do the trick! -

Random slightly cool stuff you built but not worth its own thread, thread

Raizer replied to h4nd's topic in Other Projects

I made the alloy frame (3 piece that bolts together) and the stays + brackets etc etc for some signage on a shop in town, nothing to fancy but was a good change from mowing lawns ha! Added a few stays to the front panels today, not pictured. -

Only found 2 online with pricing, around $1800 + GST. For that you can get something decent.

-

If the battery still doesn't cut it, those look like good sized horn speakers to mount in the front bumper of an E class...

-

Chris' (in)practical daily and every expense spared musso

Raizer replied to chris r's topic in Other Projects

-

Chris' (in)practical daily and every expense spared musso

Raizer replied to chris r's topic in Other Projects

Still tossing up between making/buying lowering links or just adjusting the height parameters once we get Xentry sorted out. -

Discuss here about Yoeddynz's little Imp project...

Raizer replied to yoeddynz's topic in Project Discussion

Yes, had equal length headers on my old wagon, got rid of the rumble and generally improved the sound. -

You likely just need a bigger pilot jet. Or better still a non China carb.

- 64 replies

-

My van rucs has ended in 076 since it was imported ha

-

It goes from the end of the current label. If you go over then buy more it essentially just backpays what you used.

-

Good point, the wheel spacers that failed cert on the Merc were never spotted by anyone in NZ until it went for the cert, so I doubt anyone at the local vtnz is going to spot wobbly nuts lol Oh lol and after all that with the spacers falling cert it turns out they were a factory fitted Mercedes part with the optional upgrade Carlsson wheels, not that it matters in the slightest now.

-

Wobble nuts/bolts for pcd change, I see in the lvvta info that they "should not be used" on a vehicle getting a cert. But what about WOF? No spacers etc just wobble hardware with snug hub centric rings locating the wheels?

-

I've always used a gasket scraper

-

Neither did mine on my 140, till the glue bonding the friction material on completely let go and the front wheel locked solid lol

- 64 replies

-

- 4

-

-

-

-

Might as well go the whole hog and cable tie a set of plastic hubcabs over the freshly blacked wheels.

-

It's up to the individual certifier's discretion, there's no official minimum (I went through this with my Merc, it failed on having only 1mm engagement to the CB.) How thick of a spacer are you planning on running? If you go slightly thicker than the length of the centering hub then there is stepped spacers that make it easy.

-

Discuss here about Yoeddynz's little Imp project...

Raizer replied to yoeddynz's topic in Project Discussion

Is it even really an Imp anymore with that engine? -

Looking at the lvvta chip lookup page the cert is registered to the vin not the plate, my plate isn't even listed under vehicle details.

-

I think something is trying to tell you that you need to build an angry 3 cylinder engine at some point. Echo lost a piston, V6 tried to make itself a triple etc

-

Tomble's adorable go cart / distraction / Alto Works

Raizer replied to tomble's topic in Other Projects

Wait till you try a diesel! 20 Nm, 40 Nm, 105° then 105° was a bit of a nerve wracking process haha -

Discuss here about Yoeddynz's little Imp project...

Raizer replied to yoeddynz's topic in Project Discussion

I was under the impression that they were a total no go in general unless factory fitted? I'm looking into ways to modify my Merc mufflers and hide a pair of valves in there, was told to hide the cables and controller well/try to convince WOF guys they are factory fitted AMG options haha

.jpeg.799aa864816ef8c2e211c807829f8fd3.jpeg)