-

Posts

10,922 -

Joined

-

Last visited

-

Days Won

6

Everything posted by Truenotch

-

18th New Year Jap Oldschool Meet - 19 Jan 2025 Auckland

Truenotch replied to AE25's topic in Upper North Island Region

That's pretty much all that's on Facebook these days. Along with your full name, address and photos of your licence. -

6 front, 4 rear would be nice for a comfy yet sporty ride IMO. That's what TRD used to offer in their regular springs. You could get away with going softer if you're really keen for a big softie. Droop travel is also really important for ride quality, as is compression and rebound damping. If your shocks are body adjustable you can set the total travel and use keeper springs to dial in the droop in the front. The rear is a little more tricky with an AE86 if you're still running a separate shock and spring, but there's ways to get it right.

-

Entered a hillclimb in the weekend. I'll come back to tell the story soon... for now, here's some eye candy.

- 225 replies

-

- 44

-

-

-

Truenotch's BEAMS AE86 racecar discussion

Truenotch replied to Truenotch's topic in Project Discussion

Interesting. We'll be using 50mm Jenvey on the K20 at work and also have these 48s for a back-to-back test. I'll ask the guys to make a video about it when we get to that stage. Terry Radbourne from Bourne HPP in the UK said "bigger isn't better" but wouldn't say the size he uses on their K20s over there... Just that he'd found a sweet spot that suits his builds. -

Truenotch's BEAMS AE86 racecar discussion

Truenotch replied to Truenotch's topic in Project Discussion

Wicked, thanks. My instincts keep telling me to go longer after watching your developments. We might need to model some curvy boiz to get an extra 100mm. I'll see if Connor can print some that can be chopped back easily for testing. The Jenvey ITBs we have here are only 48mm, with a 51-45mm taper through the body, so I'm not sure how much better they'll be than blacktop ITBs yet. Have you played with the distance between the head face and throttle butterfly? I'm thinking of mounting the throttles really close to the ports to counteract the size of them (and try to make them act like a 50mm+). -

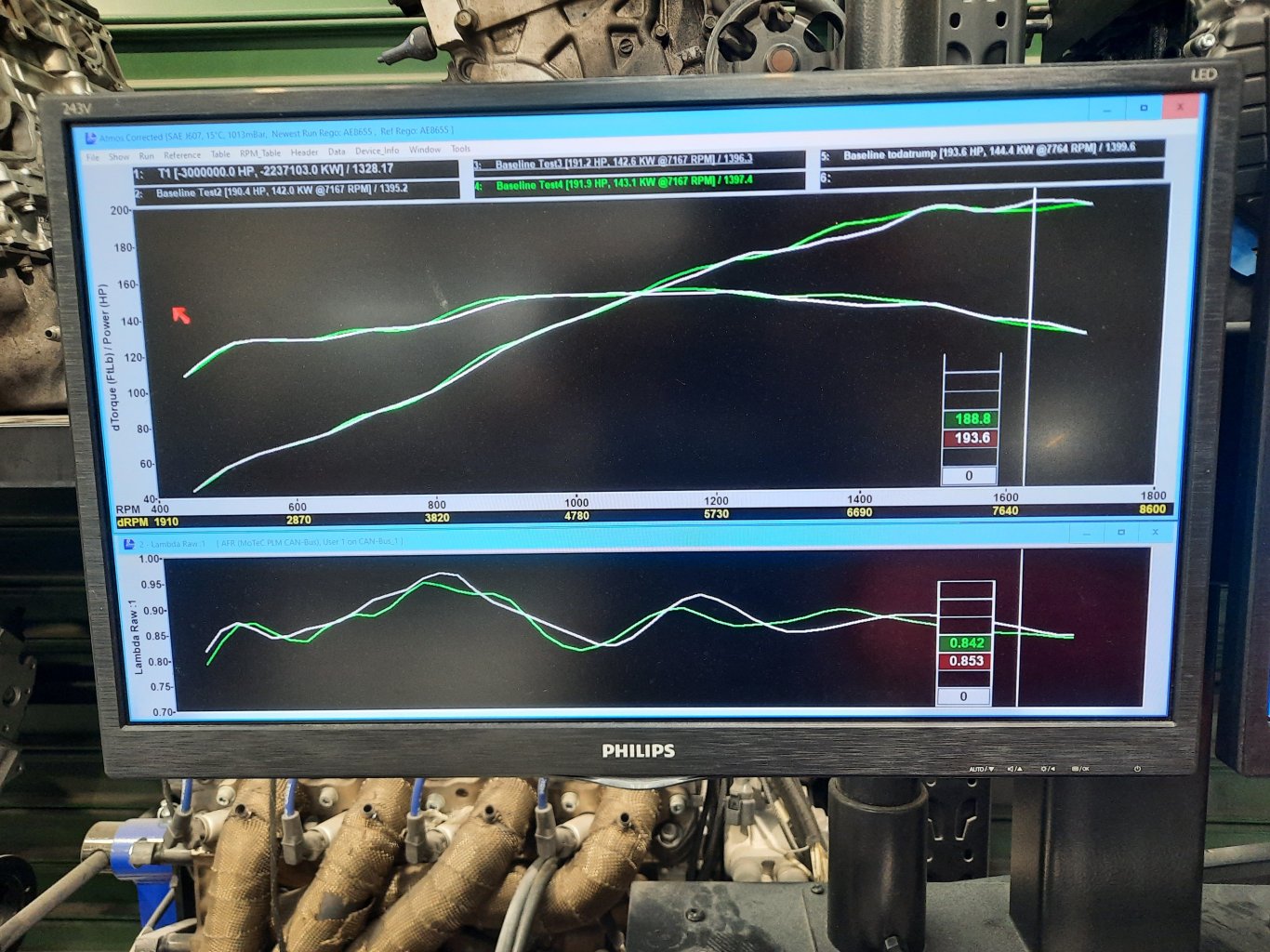

Bolted this thing onto that thing to get a baseline before making a few changes. Gave it a couple of quick runs, then swapped the trumpets from the 95mm blue ones to 75mm bronze just to see what might happen. 95mm trumpets are the green line, 75mm white line. The AFRs are pretty messy and we haven't touched any tuning, just swapped trumpets and ran it again, so maybe the shorter ones will work after some fuelling and VVTi changes? There's a set of 48mm Jenvey ITBs floating around at work and one of the guys has 3D printed a manifold to test. It'll be interesting to see if there's a difference from an extra few mm of throttle plate, and I'll give a few different bell mouths a try at the same time. I'd really like to try 50mm or even 52mm just to see if there's any gains.... will see If I can find a set to try.

- 225 replies

-

- 26

-

-

Michael14's 1959 Dodge Kingsway Discussion

Truenotch replied to michael14's topic in Project Discussion

It looks like they came in a bunch of different colours. Google image search "Chrysler flathead engine" and you'll see more. -

I can 3D scan my spare box tomorrow if you want. Do you need the housing removed, or can I just scan it on the box?

-

Discuss here about Yoeddynz's little Imp project...

Truenotch replied to yoeddynz's topic in Project Discussion

That's really nice to be able to swap back to the Datsun engine while you iron out the bugs or for WOFs before it's certed. Is it possible to get two engine setups certified? You can do it for wheel sizes. -

Progress is looking great so far! Are you set on running 19" wheels? I'm a big fan of how slammed it looked on 15s.

-

I can go one better and get a full 3D scan of the ports (we're scanning it soon to play with inlet manifold designs). We'll see how deep the Peel can scan....

-

-

@BiTurbo228 that graph is so cool. Can you add a manual dual VVTi 3SGE Beams to the graph? Happy to get measurements if you need them.

-

Michael14's 1959 Dodge Kingsway Discussion

Truenotch replied to michael14's topic in Project Discussion

Cool car! Make sure you re-use those black number plates when you get it registered again. -

Can you make two of these work? https://nzairfilter.co.nz/panel-filter/33-2931.html Maybe one of these? https://www.repco.co.nz/parts-service/filtration/air-filters/k-n-performance-air-filter-33-2193/p/A1269832

- 418 replies

-

- 2

-

-

-

Discuss here about Yoeddynz's little Imp project...

Truenotch replied to yoeddynz's topic in Project Discussion

You're finally listening to those wise folk! Don't forget to fill the tyres with water for extra traction too. -

Is that a mouse pad on the transmission tunnel?

-

That sounds like less than 8 weeks work to me.... So... oldschool drags? Stoked to see this coming out of retirement.

-

That's good info, thanks guys. I've passed on Shiny Bits' contact details for starters and he'll ask if they can handle a full wheel (I think they'll be alloys, so no way to remove the centre for plating).

-

Asking for a friend. Does anyone know of chrome platers who would do a good job of wheels anywhere in NZ? I feel like @cletus will have the answer and I'll sure more of you will have some great suggestions too.

-

I was going to try and draw this today because I think it's an idea that could actually work, but it's too hard. I'll make a cardboard flange sandwich later today to show what I was thinking.

- 418 replies

-

- 1

-

-

You could make a flappy flange sandwich (uhh... a what?) with 3 layers of flat rubber, or a layer of rubber / plastic that slides in a gap between two layers of aluminium. That way the engine can rock a bit and the flange will slide freely. No need for ramen cups if you have a flappy sandwich.

- 418 replies

-

- 4

-

-

-

How about making it out of metal and then making a part straight off that as a mould? We've done a few carbon pieces at work that way. Brandon 3D modeled an interior footwell tray, got it cut and folded, welded up the corners and then laid a sheet of carbon straight over it. Job's done. You can add foam or nomex between layers for rigidity if needed. Do that process twice to get both halves and you're sorted? Excuse my potato photo:

- 418 replies

-

- 7

-

-

Truenotch's BEAMS AE86 racecar discussion

Truenotch replied to Truenotch's topic in Project Discussion

The Imp has a blacktop 4AGE in the front. It goes extremely well. Imp purists hate it.... you two would probably get on well- 976 replies

-

- 10

-

-