-

Posts

10,924 -

Joined

-

Last visited

-

Days Won

6

Content Type

Forums

Downloads

Events

Gallery

Everything posted by Truenotch

-

PALMY SWAPMEAT 2025: 1-3 AUGUST (20 Year Anniversary!!!)

Truenotch replied to Bistro's topic in Upcoming OS Events

I can organise parking inside the gates at Manfeild if that works for you. It won't be accessible after about 6pm at night though. -

PALMY SWAPMEAT 2025: 1-3 AUGUST (20 Year Anniversary!!!)

Truenotch replied to Bistro's topic in Upcoming OS Events

Ooft, I haven't been to Daytona for a while. Keen to wear out my arms and cry about being slower than when I was in high school -

- 225 replies

-

- 29

-

-

Bit more red today. Man, the overspray goes everywhere! I was aggressively pink after this one. I'll need a bit more paint to do the roof. So far we've used about 700ml of the 1L colour.

- 225 replies

-

- 21

-

-

2025 Coronet Peak Hillclimb - 29 November

Truenotch replied to GARDRB's topic in South Island Region

This could turn into quite a party. What should we call it? Queens Boes Hill-ary Barries The Hills Have Boes HPACPHCOSGC -

2025 Coronet Peak Hillclimb - 29 November

Truenotch replied to GARDRB's topic in South Island Region

That never gets checked down here either. All the local cops seem to care about is drink driving and speeding. -

2025 Coronet Peak Hillclimb - 29 November

Truenotch replied to GARDRB's topic in South Island Region

Hell yeah. The crowds on the hill would absolutely froth that thing! There's rumours of a second hillclimb the following day over the Cromwell side too..... -

2025 Coronet Peak Hillclimb - 29 November

Truenotch replied to GARDRB's topic in South Island Region

Hell yeah, it'd be great to have you lot down here. I can host at least a few at my place and the H6 Legacy (ultimate Queenstown getaway car) will be available. @Rhyscar would enjoy it too. 165 days might even be long enough to finish his car? -

Bit o' red going down. My workmate Brandon is the man on the gun. Got the lab set up first: Got the room warmed up. Then made a murder scene at the mixing station and Brandon got to work: The results are great, which is promising for the top side! This part of the bonnet is rough because I hate sanding, but the smooth parts look lovely and glossy. hopefully we'll get some top side work done in the next couple of days.

- 225 replies

-

- 24

-

-

Don't make me regret this @dave

-

PALMY SWAPMEAT 2025: 1-3 AUGUST (20 Year Anniversary!!!)

Truenotch replied to Bistro's topic in Upcoming OS Events

Oh man, Misa moving day is almost worth a trip by itself. That's huge news. -

Dear god. The sound of that makes me want to go back to Bonneville just to hear it dopple past at 200+ mph.

-

I don't see why it wouldn't with the same level of mods?

-

Truenotch's BEAMS AE86 racecar discussion

Truenotch replied to Truenotch's topic in Project Discussion

@Hyperblade It's been like this for over 30 years! Phil (who originally built the car) wanted to be able to swap diff ratios quickly and wanted the axles to be independent from the axle, so he put a floating axle on it. The hubs are big aluminium items and the splined caps are really nicely machined from steel. I think the whole lot is custom made by Phil and must have taken him ages to design and create. I'll take photos of the hubs next time I have a wheel off it. I've had diff gears modified to take 28mm axles and had custom chrome moly axles made to suit. If you flick back through my project thread, you'll find a couple of posts about breaking the old 24mm axles. -

Truenotch's BEAMS AE86 racecar discussion

Truenotch replied to Truenotch's topic in Project Discussion

Thanks guys. I'll bite the bullet with a clean and re-weld, followed by some JB weld for safe keeping because I'm sick of oiling my brake pads and getting greasy hands every time I take my wheel off. You could say that 😁 -

Truenotch's BEAMS AE86 racecar discussion

Truenotch replied to Truenotch's topic in Project Discussion

I'm pretty sure it's porous from welding and it's been leaking as long as I can remember. I had someone attempt to throw a MIG over it in the past and the leak has persisted. The diff was making some strange noises last time out, so a full removal, strip, clean, grind and re-weld wouldn't be toooooo much extra work if the diff head and axles are already coming out. I'm not sure what the wall thickness is tbh. It's a factory T series diff housing and I'm guessing that area was ground back substantially before the caliper bracket, lower arm boxes and floating hub carriers were welded on. There's a lot of welds in that area and I'm assuming they had the mig cranked up to 11. I think the leak starts over here and might be seeping through a couple of layers of weld: One of the guys at work suggested pressurising the housing to speed up the leak and make it squirt out. Kinda keen to try that 😄 -

And I have this problem to solve... does anyone have ideas on what I can do? The diff always leaks oil out the RR corner. I thought it was the seal, so i gave it a clean at the start of the weekend and watched to see where the drips form: It's coming out of the ugly welds where the caliper bracket attaches... Should I attempt to weld the hole shut? It feels like such an oily area might be hard to weld, so the leak might persist. I'm pretty keen to seal it from the inside with something like POR15 fuel tank dealer. Does anyone know if that stuff will deal with hot oil? Your suggestions are welcome 😁

-

This part of the project feels more like shaping a surf board than building a racecar. It's starting to take shape now. I started off remaking the tunnels with 1.6mm basswood, then cut and glued some foam to give it some extra bulk & strength. Next was making the lip thicker to allow some angle adjustment without letting air under the bumper, and to give enough meat to create a nice gradual leading edge. After some hours of shaping, checking, sanding and dust mongering, it started to look like a good thing. The underside of the splitter is the part that does most of the work, so it's important to have a smooth transition from the lip to the underside. This shape is pretty close to what i was aiming for. I need to fill and re-shape a few bits before any carbon goes on. I offered it up to the car and this is what it looks like from underneath: It tucks in pretty close to the crossmember, so should be easy enough to make mounts. Since it's going to be carbon, it it needs to be light, right? Chucked it on the scales and was pleasantly surprised: Under 1.7kg for the core seems pretty good (it still has some aluminium skin that will be removed before laying carbon). I'm guessing the finished part will pretty light.

- 225 replies

-

- 13

-

-

-

It's arts and crafts night. Roughed out the shape I want from the PU foam ACM and added ramps using basswood... all great racecars have at least one piece of wood somewhere 😉 The foam and the wood have both been surprisingly nice to work with. Offered it up to the car for a sanity check. Underneath: Gave it a trim and sat it on the ground for a squizz. 👆 In this pic it has ~75mm of stick out from the bumper. It looks aggressive, but I think the intended 50mm will be the smarter choice if I want to keep it off the ground under brakes... There's still a lot of work to do. I'll be double layering a lot of it for extra rigidity, adding extra foam and shaping it to have a nice rounded lower leading edge. Once I'm happy, it'll get a layer of carbon.

- 225 replies

-

- 21

-

-

Got the car back from the panel shop. He did really nice work on the roof and bonnet, then he told me the painter wanted $2k to spray the roof, bonnet and bumper 🫠 I pulled the pin and will try to paint it myself instead. I kinda like the grey 2 tone....

- 225 replies

-

- 25

-

-

-

-

-

Truenotch's BEAMS AE86 racecar discussion

Truenotch replied to Truenotch's topic in Project Discussion

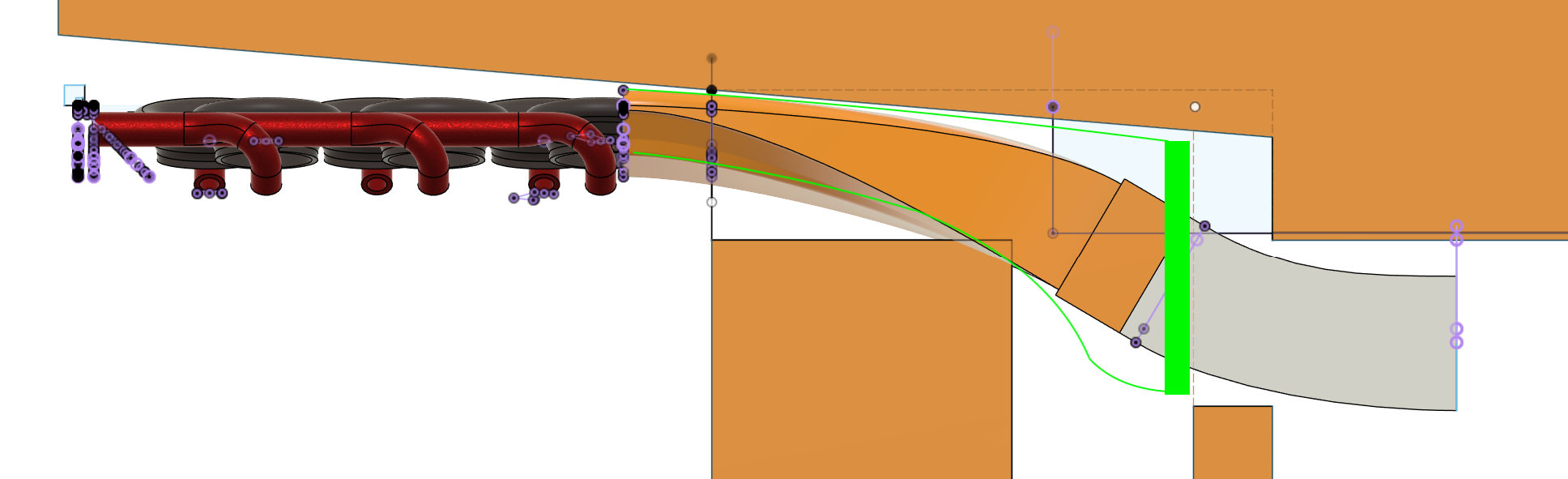

It's hard to get a photo of the inside. It spirals in to a point at the middle and out a 2.25 or 2.5" V band that's printed into the end. Designed to be slip joined in and i guess you'd run all 4 cylinders in sequence to try and get some spiral action happening. -

-

-

That seems logical. There's nothing stopping you from doing a @Rhyscar and leaving the final design of the airbox to the end of the project. Obviously it'd be cool to make progress on something now, but you can leave this bridge to burn at a later date. Filters only matter once you're driving .

-