-

Posts

1,188 -

Joined

-

Last visited

-

Days Won

1

Everything posted by RXFORD

-

I did one a few years ago for a customer to adapt a hilux uni to a navara pinion flange so we could run a surf slipjoint rear shaft section. It hasn't gone for a cert check yet though. I can't fully remember the outcome of the discussion with Clint at the time was, but I think it was a grey area as its not something commonly done. If sure he will chime in I made this one from steel to avoid any issues with internal threads Lvvta have with critical stuff made from Ali. You might need approval to make one from Ali if its threaded and would need to be 6061-T6. As long as its hubcentric and you follow the Lvv fastener requirements for shank then itl be decent.

-

Anyone here in Auckland do ultrasonic engine parts washing or even a turbo parts wash? I have a pair of Aluminium cam covers and 2 plenum halves that I have cleaned by hand and then smoothed out/shaved for polishing. They need another good clean to get all the Ali filings out of before I send them to Rkm. If theres nobody on here doing it I'l go visit some engine shops.

-

Suck it up, throw ya nuts over your shoulder, crank some Slayer, and fix it properly. If everything else has been done then its just lazy leaving that shit.

- 15 replies

-

- 11

-

-

The main thing to look at is the duty cycle. That xcel arc 230 is a bit better than the 195 thats rated at 15%. But for the price its still a bit average. I think thats the trade off with alot of those multi process compact machines and I guess its relative to budget and what you will use it for as to whether the dutt cucle matters that much. But theres always much better rated 2nd hand gear popping up for the same kinda money.

-

Its critical. I think I was about 50kg out on my b2000 with 215/35r18 and ended up having to raise truck a bit and fit 225/40r18 to get the right tyre load rating. You'll just have to do what ya gotta go unfortunatly as you can't de-rate.

-

Thats really piss poor and amateur of them given how many people have a gmail account. Considering the Govt ruled that the Ccm be made freely available to Nzers I wonder how well that would go down if brought to light publicly.

-

You looking for a single or 3-phase setup? I have a Lincoln Pc60. Blows through 16mm steel and 12mm Ali like butter. But they are 3ph. They pop up on marketplace every now and again for reasonable money. Or the Miller Spectrum range are a good bit of kit.

-

I think you can make FC rx7 crown/pinions work in 90s b2000 nuggets with a bit of fiddling to give you better freeway gearing. Or maybe the whole head swap over but rx7 length length requires d-shaft to be shortened. And possibly those light trucks (Mazda Brawny?) that have the really small rear wheels. Its been a while since I read up on it but think those are the only ways to get high 3.xx or low 4.xx gearsets for UF B-series.

-

I'm assuming its glass and on a shortened beetle pan? Who made the body? If its glass and on a beetle pan I would think it would be treated no differently than a vw beach buggy so it would end up as a 'scratchbuilt replica' But if its on a 356 pan it could be a different story.

-

Chuck some pics up of the offset engine mount situation before you get too involved in it. There will likely be a limit to how much offset the certifier will allow.

-

Probably worth doing the vinegar test on them before putting any cleaners on them. I would probably have them vapour blasted and ceramic coated.

-

Random slightly cool stuff you built but not worth its own thread, thread

RXFORD replied to h4nd's topic in Other Projects

Hell yeh, thats cool. Now every time you hit the spacebar a few little rust flakes will fall out. -

Kp60nick's D21 kingcab Soon to be Bagged on Cadillac Escalade rims

RXFORD replied to kp60nick's topic in Other Projects

-

Try swap the pos and neg cables over to work in Dcep instead of electrode neg like it is.

-

Good tip. Maybe I should start wearing pants around the shop. Wouldn't be fun getting my pubes ripped out by my spinny tools.

-

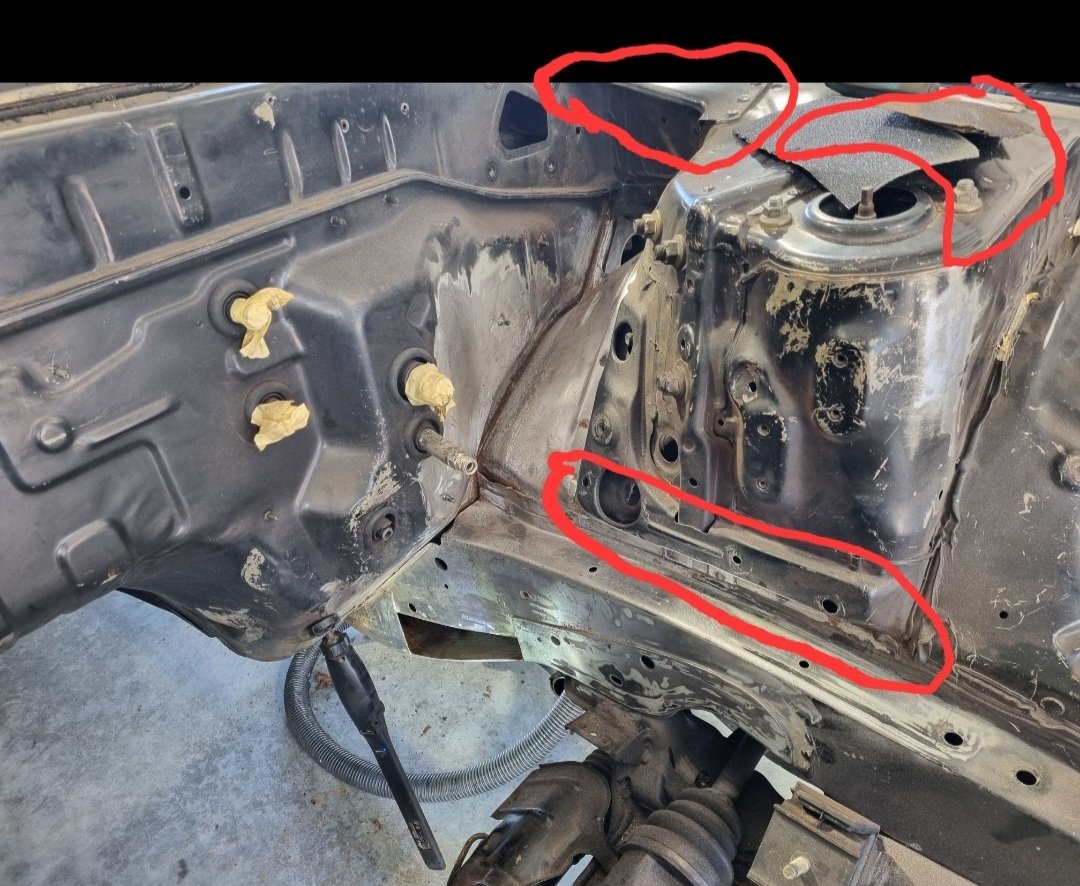

Because you are old and blind, grab one of your fancy new workbench lights and have a good look for any swelling of seams in these areas. Could be hidden by sealer. 32s & 33s are notorious for blowing out around them. Might have to have a gander along the rail seam from the strut side, from memory they are triple layered. Top seams of strut towers, and the gusset between firewall and top guard mount area usually go at some stage too. While you are at it, around the outside of the area infront of the A-pillars below cowl. And the bottoms seats of the front and rear windows are another common rust spot. Oh and the chassis railettes under floor pans too. Hopefully yours doesn't have any of these issues, but they all seem to do it at some stage. Would hate for you to spend all that time fitting the Ld28 just to have to pull it out again for more rust work.

- 120 replies

-

- 13

-

-

-

Rear tailgate window rubber perimeter trim.

-

I have a rear window with seal and stainless trim if you would like a spare.

-

A build thread? From Dudley? You feeling alright, must have gotten laid or something today? Can confirm super good wee car. Got to hoon it round the block. Took me back time when I was 16 and me and da bois were baseball bat guard rolling these things to fit spittys and eagers with no springs. I'm disappointed you didn't add pics of the super ultra mega fucked parts bugeye you ferals drove back.

-

Rfid Cert donuts cause chemtrails?

-

Its a thing that responsible adults and non-poor people have so thier insurance is valid.

-

I rekon that munters will soon treat cars with the rfid/gps/facial rec/ankle monitor cert tags will the Lhd Rotarys of the sale world. $20k less for same car with one compared to a old plate style.

-

What diam wire are you running in mig? Getting doors off yahoo shipped over would be an expensive exercise. Surely a local shop could do some corner patches for ya to save the hassle of importing shit thats probably just as bad?

-

Go round to a few old panel shops that have been around for ages and see if they have an older Car-O-Liner Mark4 setup that they might not use anymore. That would be the ultimate setup to use. You might get lucky and be able to snag one with measuring gear for a few grand as most smash repair shops have upgraded to speed-benches/digital gear. Or you might be able to make this work... https://www.facebook.com/share/1A3VN7fsgK/

- 1 reply

-

- 2

-

-

I can't see why there would be any issues with extending the front subframe legs as long as the material isn't a fancy high strength steel and you match material thickness with suitable gussets/fishplates. It may be something you need to start mocking up and tack togethor, then take to your certifier or send pics to Lvvta to make recommendations on. Its just going to be hard for them to ok something unless you do a super detailed 3d model. Same again for your plan for the rear mounts to the chassis. As long as the area where the stud is gets strengthened well so the load is spread to avoid cracking then it should be fine. The shock towers will definitely need reinforcing to be suitable for a coilover strut. Adding a 'strut brace' would help too whether its fixed in place or removeable.