-

Posts

1,771 -

Joined

-

Last visited

-

Days Won

1

Everything posted by fletch

-

Plz do the 3kw 48v hub motor and use a 72v battery pack.

-

Lol that's a big dog. Yes they do coke up if they are not loaded. Can take a while to happen but does happen. Example was a camp generator. Nice 4cyl perkins turbo. Ran for a couple of years 50% of the time it had no load really. Ate itself and nearly ran away. Was a bit exciting. Mechanic pulled it apart to have a look and it was curtains. Then he left and the container door got shut.... Starter motor and alternator fitted my tractor tho

-

We have a few of them at work for small site backups. Heavy little fuckers. Have been very reliable. Will start a 2.5hp single phase air compressor.

-

Luck of the draw I would say. Some 2kw generators would do it. It depends how good the generator protection is. You could try it on 2x 30m leads joined together. It will lessen the voltage drop at the generator, but not really practical as a long term solution. Single phase can be a bit of a prick.

-

Bugger. See this link for a good explanation of how the original reg works https://240z.life/voltage-regulators/ also i think this covers it, even tho its slightly different. Also mentions auto choke relay near the bottom of the page. The 510 diagram you posted looks like it suits your wiring, but the pins in the plug are different to Kickers photo. You must have the Yellow wire in your regulator plug splitting off to the choke relay coil and its not shown on your diagram. You could do some probing with a 12v wire onto each pin of the regulator plug (car side) and listen for the clicks of the relay to confirm what feeds it. Just don't touch it on the ground pin. Im surprised the light is staying on when you connected it directly to the alt and the S to the battery. Have you got a voltmeter? Did the voltage rise once the engine was running? I once did a rush job engine conversion on a 90s nissan. I had the S wire connected but i hadn't run the charge light wire to the dash. Temporarily i had to start the engine, then touch a wire from battery positive to the L terminal to energize the field and get the alternator to charge. Once it started charging it was away. If your charge light is staying on, there might be a problem with the alternator?

-

I think the S wire is sending volts back to the ign circuit the way you are trying to connect it. Can you try looping the charge light to the L and temporary hook the S off the alternator straight to the positive terminal of the battery. It's just a reference signal from the ign circuit so the alternator can up the volts if there's a big load and the ign circuit volts are dropping.

-

We had a problem with some caps failing on some equipment bolted to one of our gas compressors. We got the upgraded factory device and i dissected it to discover they had just put a blob of hot glue against the cap. Still going strong 17500 hours later

-

Just put it on the dyno and adjust it until it goes best. If you haven't got the bling cam gears, run 2x timing belt tensioners. Then you can adjust them both at once and you only need to buy 1 2nd hand gear with the anodizing worn off to adjust them independently.

-

3RZ. They came with a W series box too. Can buy a 1500hp kit for them from paradise racing too

-

If some is good, more must be better right? I read another joker took a lick off the end of the pushrod that actuates the clutch to get the right clearance. It was my 2nd last option. Last being spending more money on the correct sized end plate from Japan. I understand that as long as they are set up right, there is bugger all wear on the plates and they should last a long time.

-

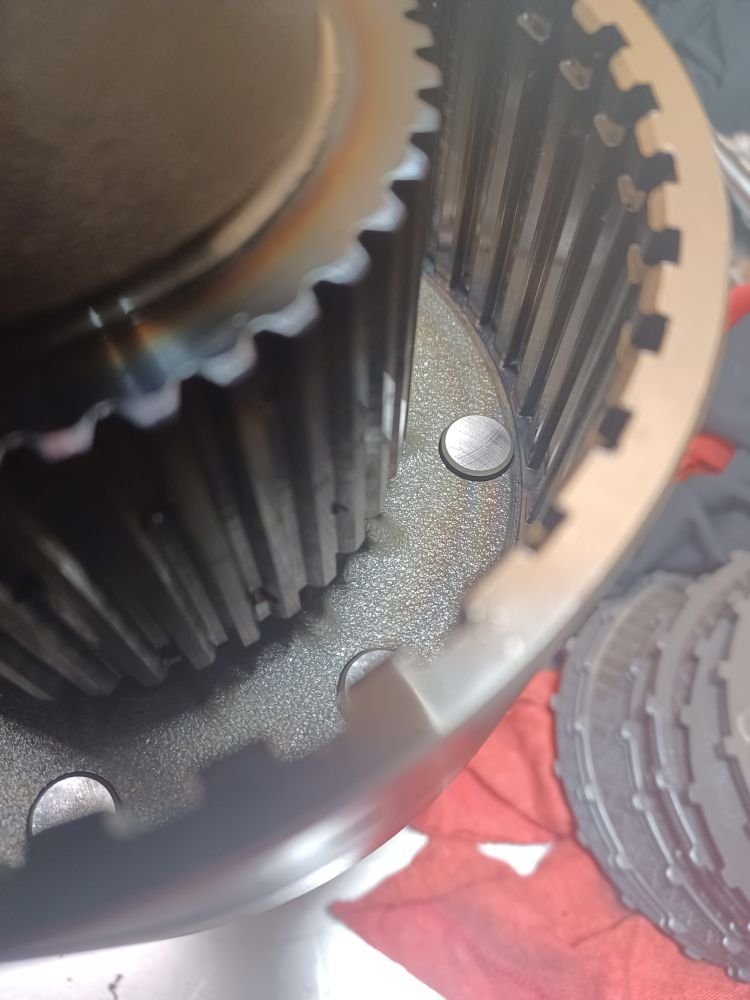

the clutch pack goes in here and the actuator pushes the pins up to clamp the plates together You can see there is a difference in height of the inner splines to the outer basket. I was stumped why the plates did not line up. I stripped the inner assembly and found the thrust washer and needle bearing clamp half washer thingys had fallen out I got it all together correctly and back into the case then put all the plates in. There needs to be the correct clearance under the main snapring otherwise it will either be locked or lazy as. I was close but not within tolerance so out with all the plates and measure them all and assemble with all the thinnest ones, but still too tight. Then i tried the thin base plate and all the thickest clutches and drive plates and it was too loose. The front plate can be ordered in a bunch of thicknesses from nissan but thats 3 weeks plus I ended up running the R33 shaft and basket in the R32 case as it was .3mm different depth and everything worked out. I had to play the thrust washer game again as it was different... But it does have a splash guard that helps stop the oil coming out around the gearstick. This was me for about 4 hours. Plates in, measure, swear, plates out, measure again, stick in different piles according to thickness, and reinstall and measure again etc. Then try with the R33 basket and shaft. Every time i got stuck, it was back over to the press to push it apart or back together, and repeat. Fortunately the shims for the front plate are within tolerance so i just need to clean it up and glue it on tonight. Progress might be slow now. Waiting on the head, and need to do some work on the wagon for wagnats

- 54 replies

-

- 18

-

-

-

Just waiting for a mate to come round and help set up the diff. Hopefully soonish. I made a start on the transfer case as i was on a roll. The clutches are inside the shiny drum. For some reason Nissan engineers built a great transfer system, then only set it up for about 60% of its capacity. These are the plates out of the drum. You can see they only have a friction plate installed between every 2nd driven plate. Standard there is 7 frictions and 12 drive plates. Max capacity is 10 frictions, 9 driven plates, Plus the 2 end plates. I had another transfer case in stock so i robbed the plates I have changed the bearings and seals over and cleaned all the parts ready for reassembly and done a dummy fit, but have found a bit of an issue with the inner-most friction plate running off the end of the splines. I was going to run the 32 transfer case as it takes the R32 cable speedo. but have a 33 case with some minor differences that make it a bit better maybe. Just waiting to hear back from some kebab shop owners in oz who know about these things before i slap it back together. When i pulled the transfer case off the back of my gearbox, i noticed a heap of magnetic sludge in the back of the box. I have all the bearings and seals to re-kit the box, but not the synchros and they are $$ plus waiting time for japan. A brand new box is $2700nzd in japan, plus shipping plus duty which is around $4500 all up. I wonder if i can get it bought over in a container?

- 54 replies

-

- 19

-

-

I stripped the ring gear off the stock open front diff and installed it with some new bearings onto a quaife torsen lsd. Lots of guys on the SAU forums rate it as the best mod to their GTRs. @Bistro came round for a few beers and gave me a hand to install the adapter plate and test fit the sump. Had to come off again as there was a bit of extra clearance required on some of the adapter plate bolt holes Its all on now, and i fitted all of the diff parts with new bearings and seals everywhere. I jumped ahead a bit and fitted the pinion seal before i measure the end float so that might have to come off again. Fingers crossed its ok. I got the crown wheel backlash perfect at 0.15mm. spec is .13 - .18 Pretty happy with that. Need to paint the gears next and hopefully the pinion is ok and i can seal it up. Its a prick of a thing to fit the diff in so im hoping it does not need to come back out again. The hardest part is waiting for parts. I can buy all the seals and shims i need, but they are usually 3 weeks from overseas. Once the head comes back i can fit that and do some plumbing and fit it back in the car. I might do the transfer case next. Maybe overhaul the gearbox.... Its a slippery slope

- 54 replies

-

- 28

-

-

-

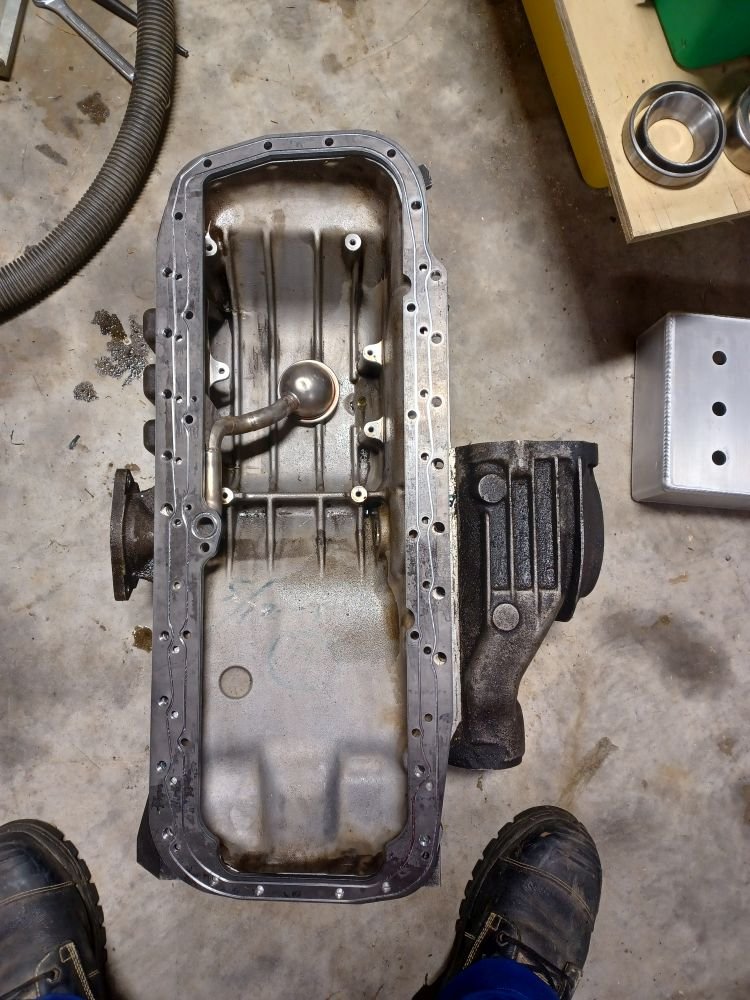

I bought a RIPS sump extension and adapter plate to modify the sump. I have my original adapter plate, but it was a bit of an amateur thing done ages ago. The rips plate has an integrated oil pickup and a few extra features that are an improvement on mine. The plate also has a double o-ring seal, which might seal better than glue especially if im going to probably have it apart a few times - hopefully not, but RB's do love a good run bearing I got a wizard to do the mods to the sump and add on the extension. He made it look so easy and did a beautiful job. also drilled out the oil return holes under the axle tube as they start at 5mm but the last bit of the holes is around 2mm which wont do much

- 54 replies

-

- 12

-

-

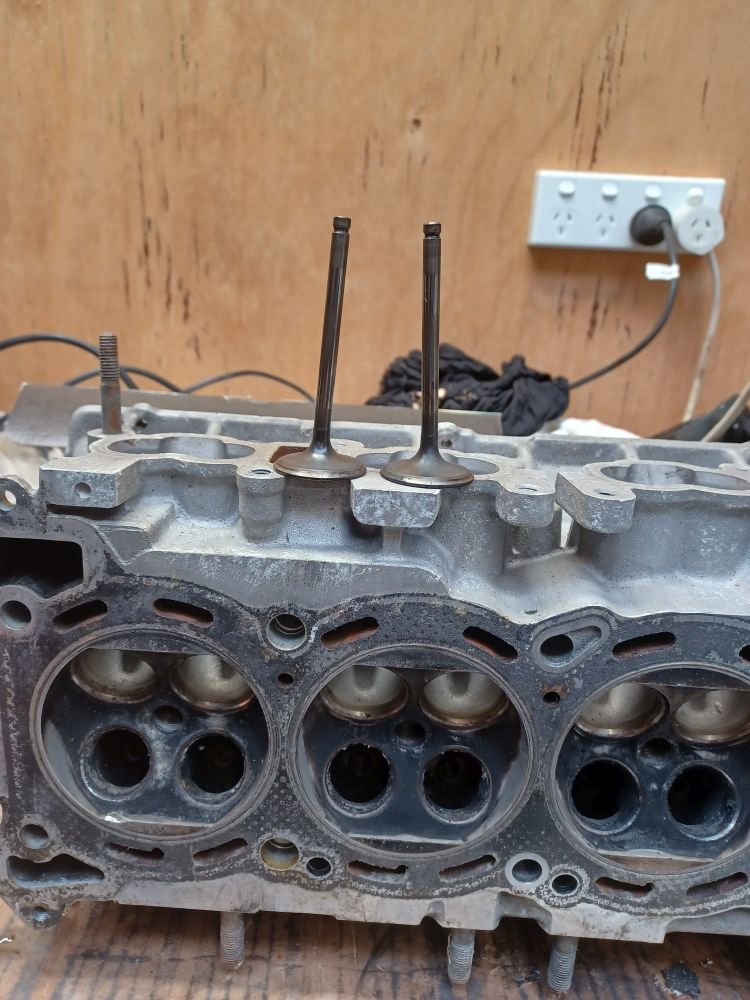

So the usual 3 or 4 weeks in OS time was 3 or 4 months. I stripped my old head with the hopes of giving it a quick valve lap and send off for a skim was a bust as most of the lifter bores are scored. I must have had some shit through the motor at some stage. Lucky @Ja1lb8 to the rescue with a spare head from a one day project he bought back from oz This is a turbo head - they are the same NA or Turbo, but the previous owner in Oz had copper fire rings added to help seal with a stock gasket. It would be at least 14 years ago that Ray bought it. Must have been before everyone got the MLS also, sadface Anyway, drilled and tapped a fitting for the VCT oil feed like this, but in the new head and dropped it off to the machinist with some spare valves, and a set of Kelford cams and springs. Was hoping to have it back by now, but hes under the pump like everybody so maybe end of january

-

Maybe a ride height sensor fault, or difference between them

-

I have played this game before. 32 box is cable clutch, 50 is hydraulic. 32 box has smaller gears, not necessarily weaker I think. But this means you need a 32 hanger bracket off the back of the motor for the right hand shaft as its closer to the engine than the 50 series box. Manual cars also had a mount on the front of the crossmember to help reduce the shock load. Especially if you want to operate the clutch and gears in a manner befitting a certain character from chch who can tell a story

-

I think air flows from left to right in that pic. Filtered metered air comes in at the left and goes into the IAC, FICD, and idle screw block and gets into the manifold its bolted to control the idle. Air also goes into the left of the 'air reg' which is actually the cold start air bleed. It is bolted to a water pipe and has an element in it that is connected to ignition and as it heats up it closes. Yours could be stuck open. Take it off and block the hoses to see if that helps. A couple of squirts of brake clean should flush it out if it's scabby. Skyline ones fit of you need a replacement. Yes the vtc actuator moves a piston in the end of the cam and pressures up the pulley. All it does is advance the inlet cam a bit. they are common to leak with age, and usually causes a rattle from the inlet pulleys. Don't think it will change the idle rpm tho.

-

they have it on both inlet cams, see the bulge in the timing belt cover.

-

Use heaps of them on high vibration stuff at work. The good quality lugs will hold on until the wire breaks.

-

Have you got plenty of Tyre pressure? I run some $8 deestone sack barrow tyres. They seem to last a long time for me and im pretty heavy and ride it on all kinds of rocks and shit

-

Maybe it's just electrical load. Your injectors and coils would be working hard as rpms rise, and there is only .6v difference. At 6:20 the voltage jumps straight up as soon as the load drops.

-

you can buy the same fitment alternator here https://franklinperformance.nz/products/oex-140a-ls1-alternator-mxa306 edit - $399, maybe cheaper on rockauto? i have one for my rb30. Haven't run it yet, but its a common mod for RB's as its a bolt on. The OEX brand one i got appears to be well manufactured like the jap ones i have and has the same mitsubishi plug

-

Next mission is replace the exhaust as its falling apart. Then do the timing chain tensioner as its pretty much gone. They wear through and then over extend and fall out. It's on its last legs. It's an engine out job to do it properley as you need to reseal the sump. Then maybe a manwell swap, possibly at the same time. I do quite like the whole not changing gears part of the auto. Maybe I'll fit a later 4n71 4 speed auto And then sell the super six, i have a few of them in stock, and that will fund a paint job on this one Edit- I was going to sell this as it was an impulse buy, but I really like driving it.