-

Posts

1,376 -

Joined

-

Last visited

Everything posted by shrike

-

Good point, I was thinking if no coolant was flowing then it wouldn't read accurately either. Ive driven engines short distance without coolant (didnt realise due to where the leak was) and had the guage not read correctly.

-

@mlracing.co.nz If you had no coolant in the engine your temp sensor wouldn't have read it was overheating as they need fluid to read correctly. In regards to the carbs, personally id be looking at efi options but thats just me 😛 Have you done a comp test on this motor? If you have issues from overheating (ie headgasket) is it possible the 2nd carb isn't drawing as much because the cylinders that are closest too it aren't pulling as much vac? Note im useless with carbs but just a thought

-

@Roman did you track down a 1mz crank?

-

Ahh didn't realize this was for turbo, was thinking N/A for some reason ignore me and carry on :p Keen to see updates either way, also curious what turbo your going to choose given the high RPM

-

Please tell me your considering DBW ITBs as well? Few RB26 options these days And hows the rb20de neo head compare to the rb25de neo head? Guessing it'll have a smaller combustion chamber so more compression then the 25 head? Assuming you'll be doing the normal crank collar/oilpump, oil drain/oil restriction mods?

-

Ive heard that V motors sound better with an X pipe.

-

Daves new school holden shambles. (Is this project oldschool yet?)

shrike replied to Muncie's topic in Other Projects

Got some front drag wheels for next OS drags?- 744 replies

-

- 2

-

-

250kw per ton is a pretty happy power to weight

-

Sub a Ton without driver if super Awesome Weight basis is pretty good and options to tweak it

-

A lot of people delete the clutch distribution block and just run a new braided cable between the master and slave cylinder

-

Wasn't sure what thread to ask this on but @kpr the VVTI pully from the JZ family was there a reason that worked better then say the Altezza 3sge VVTI or the 1GFE VVTI pulley? Or was it more about part availability?

-

So did some digging and there is options to modify the Valve/Cam cover to gain some bonnet clearance as needed https://kpower.industries/products/modified-k24-valve-cover-for-na-hood Or if I want to spend crazy money https://dragcartel.com/products/k-series-billet-valve-cover-with-fuel-pump But at least there is options

-

Starting to think I need to organise to come over for a couple of weeks, work out of NZ and make a proper plan/acquire any missing parts

-

Yeah scope creep is a massive issue Not sure what will be done before I am over next so will keep having the chat Its ae115 gearbox spare so same rear diff as the celica Ive got 2 blacktop heads, a complete 7afe, could pick up some rods and forged pistons etc but could just get it running with the 7a which was the last chat I had, was thinking the K24 would be easier path and better power potential but clearly that isn't the case Can always swap to K series when I move o it over here (im looking at cheap honda gearboxes sunday)

-

Chris' (in)practical daily and every expense spared musso

shrike replied to chris r's topic in Other Projects

Have you considered just using some metal bog or JB weld type fix? -

Street driving in NZ may be possible depending on where it ends up modification wise and if I can get it certed etc Street driving in Australia is a no go as ill never be able to get it registered here with a cage and I'd need it stock to get it complied Rego is on hold but im pretty much consigned to it being track only I am also more keen on just competing with myself then being super competitive against other people I can always use the K24 on something else long term or onsell/hold it etc and I haven't brought too many K24 specific parts So I still have options Edit: its also incredibly hard not being there to do things or work on the car/ see progress, if I was to do this again I think getting the AE115 I got as spares id just have kept my original 4age made the car AWD and look as stock as possible for that. Enjoyed the car and then done mods as I went along, id very much like to be in a state I can enjoy the car again

-

Looks like my options then are (in no particular order) 7afe to get it moving and use my existing parts to get some seat time (can turbo/4a head etc as I go) Covert the Celica gearbox to Fwd and give up on AWD (off the shelf adapter kit available for E series boxes to K24) CRV gearbox plus the extra bits to use K24 2ARFE? See what options I have to go back to close to stock Part out Burn it with fire 🔥

-

Shrikes Will it ever be finished Toyota Levin AE111 AWD

shrike replied to shrike's topic in Projects and Build Ups

Yeah if I went the CRV AWD route id be pinning/locking the transfer case so its full time AWD and id be running a real diff at the back thats not electronicly controlled. Though thinking about it, would there be a benefit of only having the awd kick in when needed? Still it would probably need mods it handle the power output -

I can still pull K24s for 300-500 at a Wreckers. But they are alot higher km now

-

I feel this, but considering id have to make the car factory to bring it over here, which is pretty challenging as id need almost a crashed car to do it. Also my options to sell up are a partout and I cant do it to myself And it's gotten really hard to have a modified car in Victoria. Id be lucky to have the car road legal with a half cage. Need to see where things are at when I come over and rethink based on what's in front of me. But at least ive got most of the parts to make a call, and part of me is already so far into it I might as well see it through. Might still be a possibility to get it certed with a logbook and motorsport licence in NZ. Id really loke to get it done enough to bring to Aus and then tinker on it in the shed. Try and make as many events as I can I am trying to dial back my build and make it enjoyable. Im really trying to avoid sinking too much into the engine or gearbox currently. If the K24 ends up being unviable then that will be a rethink. Can still throw a 7afe and e59f into it lol 😆

-

I was emailing the guys at Drag cartel April last year "T case 500-600 HP range need to start upgrading internals and outer case" https://dragcartel.com/collections/all-wheel-drive/products/awd-k-series-gear-combo-and-case https://dragcartel.com/collections/all-wheel-drive/products/awd-k-series-combo-special Not a cheap exercise however, think there is a couple of other options as well TBH id probably have a spare and if I break one id dial down the power until I could save up for a fully built setup Id really like to stick with the Eseries box if I can (wonders if I should try track down a 2arfe again lol) This is what you need to convert a normal honda K series 5 or 6 speed to AWD

-

Shrikes Will it ever be finished Toyota Levin AE111 AWD

shrike replied to shrike's topic in Projects and Build Ups

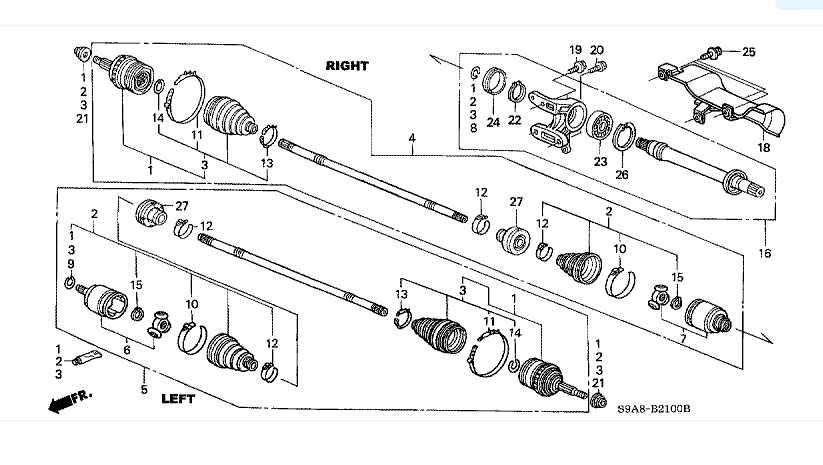

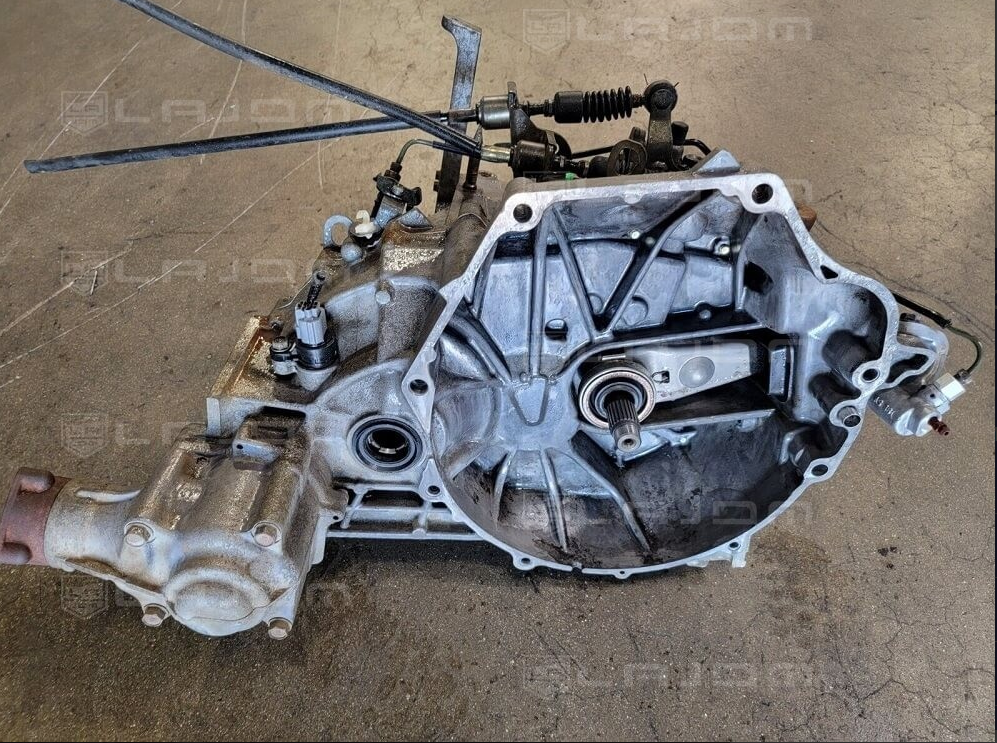

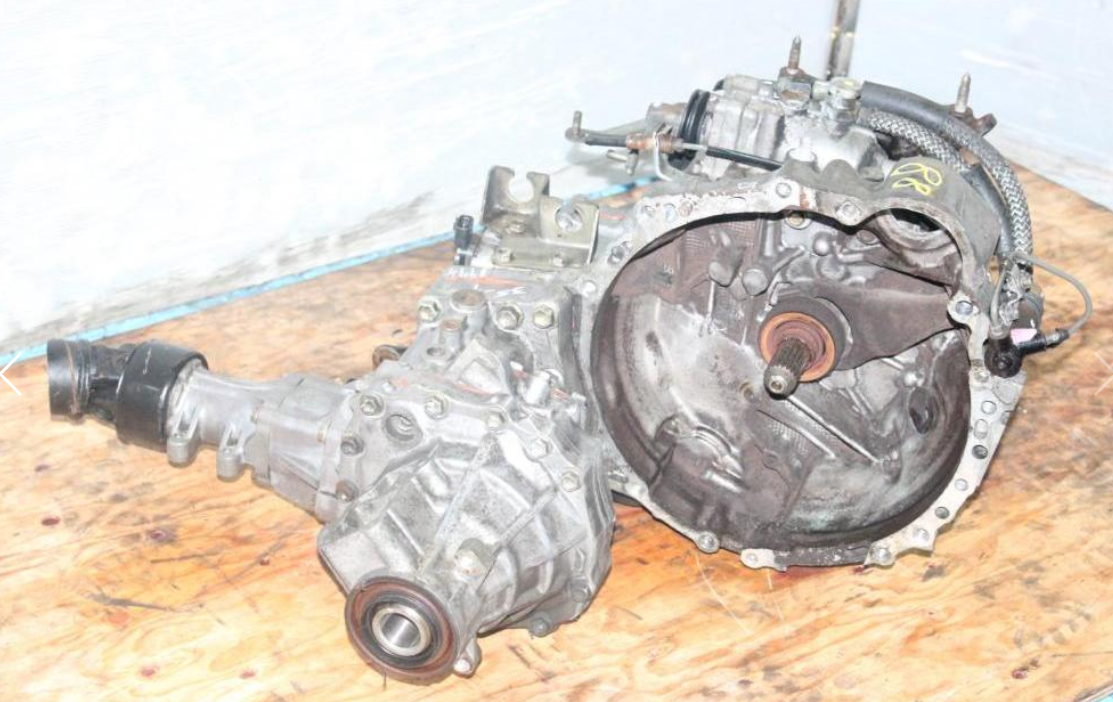

So was emailing a little with Uniclutch today as I saw their product on the latest Mighty Car Mods GTR video and I also sent some notes to Steve as well https://www.youtube.com/@uniclutch And I thought the idea was pretty cool, as I am not sure which gearbox ill be using yet a clutch that can do both is very appealing Disclaimer most of the pics below are found on the internet and not of my actual items Clutch notes: Honda CRV gearbox has similar bell housing clearance to the GT4 gearbox Uniclutch do some interesting clutch options they don't currently do custom flywheels (plenty of places in NZ do custom flywheels though if needed) They offer a clutch kit that you can change the splines on so one clutch could work with either the CRV or GT4 gearbox "550kw and roughly ~840 Nm power, you'll be at the safe limit of the 8-inch Track UniClutch (which is the only unit that will fit K24 and 3SGTE). it will still be usable and safe, but if your power goals exceed this, please let us know as you may need to work out something more custom to adapt a 10-inch UniClutch instead." So the 7.25" clutch options ive been looking may not have been great long term but its still a consideration to explore as id been looking at Tilton and Quartermaster clutch setups I like the uniclutch option as it means I can use either gearbox, the UniClutch Track drives amazingly. you'd be surprised it was even a heavier duty clutch than OEM. yes, we have a fitment ring for the K24 and also the spline for the Toyota gearboxes (21T x 29.0mm). depending on which flywheel you end up with, the spline will most likely be included. we also have the spline for the CRV gearbox in most of those kits also if that's the path you'd like to take. the UniClutch diaphragm design works with hydraulic and fork style release bearing. you just need to be aware of the 48mm minimum bearing contact diameter. if you have a hydraulic release bearing you'd like to use, send it through and I may be able to confirm over email if it's good. as mentioned, we don't have a flywheel available. the UniClutch will bolt to the majority of OEM and aftermarket flywheels using the appropriate fitting kit. rule of thumb is that if an OEM clutch works with the flywheel you're choosing, then we will likely have a fitment kit to suit. Gearbox notes: The CRV gearbox doesn't have the CV shaft come out of the transfer case like the GT4 Box, as you can see below it has a half shaft similar to a fwd gearbox I know with the E153 Gearbox from the MR2 the Half shaft is bigger and is pretty tight "Cannibal" Kit Instructions | Hux Racing And they redrill the 3SGTE flywheel to suit the K24 Crank bolt pattern K24 Flywheel is the same Diameter as the 3SGTE flywheel 305mm and both are 120 Teeth K24 Flywheel is more compact then 3SGTE flywheel I am not sure if we could shave the block and the GT4 transfer case to make it fit, and id rather not shave the GT4 transfer case, as if it won't work then id like to try sell it as I think they go for ok money (esp with a front LSD) I wonder if there is an option to do a Billet transfer case that would be smaller diameter? The AE115 Gearbox (E59F) may have a smaller transfer case but im not sure it it would fit on the GT4 box plus I think its a narrow gear instead of a wide gear (May have confirmed its Narrow below as the 5th gear cover us Steel rather then Cast) Which is why I got the E51 or E52 box with the 3rd gear issue as it was wide gear so the bell-housing should work on the GT4 box as I am unsure if the narrow gear bell-housing would work Im also not sure which of the 4A or 3S bell-housing will be the best to work with for an adapter anyway, I think I prefer the starter motor location on the 3S bell housing but the 4A might be better as it gets it at the back of the engine And im more open to modifying the 4A bell-housing as its on a box (E51 or E52) that already has issues with the 3rd gear Also while I remember (I don't think I need clearance however) The Narrow Geared E Series boxes (Rav4 (E250F), E56 & E58 (AE101 GTZ) E59F (AE115?) have a steel 5th gear cover that is smaller then the Alloy cast cover so may be an option to swap if we need clearance on that side. To fit the CRV box we would need to Gear selector setup? (not sure if my existing one would work) Shorten and re-spline both front CV CRV axles to work with Toyota ST185 or ST205 Front outer CV joint Custom prop-shaft (transfer to diff) (not worried about this as most likely needed one anyway) Modifications to correct diff ratio as front and rear don't match (even factory honda diffs don't at 2.529:1) (multiple options below not sure if I really like any of them tbh) Factory CRV isn't full time AWD so the diff ratio not matching isn't an issue as the rear diff turns on and off as needed Auto front transfer case and run 35 profile front tyres and 40 profile rears to get the diff ratio closer (and if we haven't pinned/locked the front transfer this should be ok to start) Custom transfer gear 0.3778 ratio (factory is 0.434 for the Manual and 0.393 for the Auto) Custom Rear diff ratio of 2.549:1 (hard as nothing off the shelf and the Celica rear diff is a 6.7" T series diff but is potentially different to other T series) Factory Celica ratio is 2.928:1 Auto front transfer case and change rear diff to a Jag X type X400 (Currently no LSD option but one coming, and the diffs are pretty cheap so I could get two and weld one up etc ) New rear diff mounts to suit Re-spline and shorten rear driveshafts to suit Toyota ST185 or ST205 Rear outer CV joints There is also a corvette that has a 2.59:1 rear diff but its not a very common diff so availability is an issue Can happen later ie once the cars going and potentially shipped over to me in Aus Front LSD Pin/lock CRV transfer case so its 100% AWD ( there is a clutch pack option for this) Might need billet transfer case and upgraded transfer gears depending on power being run CRV/Honda gearboxes in general aren't know for taking power so would probably need to build it with a gear-set to handle the turbo Maybe I need to start stockpiling gearboxes along with engines :p Though I may pick up a cheap complete CRV if need be Edit: adding to this the E51/52, E56, E58, E59F, E153, E15XF & E59F all share the same clutch Spline of 29mm and 21 Teeth. Factory 4AGE (20v), 7AFE/4AFE (FWD gearbox) are 23.8mm X 21 Teeth. -

@xsspeed am I misrembering that RB25 rods will fit an RB 20 crank? I thought Maxspeeding made RB25 rods? If they are similar couldn't they use the drawing from the 25 rods modified to your specs?

-

Shrikes Will it ever be finished Toyota Levin AE111 AWD

shrike replied to shrike's topic in Projects and Build Ups

So even though the listing for this says the below ports are 3/8NPT they are in fact actually ORB 8AN M20X1.5 but M18X1.5 fit (a little loose) 3/4" NPT is huge and I don't know why they would fit Why I don't know, its possible they are 5/8" NPT and its a typo but that doesn't match up to the measurements and the bungs it comes with screw into my M20x1.5 M18x1.5 Nope Oil cooler kit is mislabeled and it came with M18x1.5 and M20x1.5 fittings not M22 and M20 like I thought Luckily the Honda oil filter is M20x1.5 So ill get some 8AN to M20x1.5 8AN to M18x1.5 adapters, one side will be my turbo coolant return as I probably won't run a heater circuit anyway So the 1x 8AN tee with a 3/8 NPT 2x 8AN to M20x1.5 Are both spares To add context on the factory K24 coolant setup one port is for the heater return (front) and the other (Back) is for the coolant bypass The coolant bypass brings water from the head and bypasses the radiator until the thermostat opens Also my obsession with running AN fittings and lines for everything possible is getting silly, I was trying to track down options for a 1/16 NPT to 3AN fittings so I can run ANfitting/line rather then normal silicon vac hose on my Fuel pressure reg Ill be going for an EGate when I go turbo so no vac lines to worry about there, and my brakes are non boosted as i've gone to a pedal box Starting to think I won't need many vac ports at all -

Have you considered a 1AR or 2AR :p And I feel you, keeping with the A series for me no longer makes sense due to the time its taken for the build Though I am getting worried the Honda K motor is a little old but at least heaps more support and availability Do you have a couple of 2ZZ in the back of the shed? I am going to start pulling motors out of Accords in the not too distant future and aim to have 3 motors (including the one in the car)

- 417 replies

-

- 1

-