-

Posts

6,542 -

Joined

-

Last visited

-

Days Won

4

Content Type

Forums

Downloads

Events

Gallery

Everything posted by BlownCorona

-

most of the data plate was worn away but i was able to figure out what most of the stamped in number where by comparing it to my drill press. ill re do that and let you know. ultimately im totally fine with just getting a better set of pulleys or adding a jackshaft if the $50 controller isn't actually a good idea. id rather not get the controller and have to buy a new motor aswell. my drill press could do with a better set of pulleys as one of them is fucked so maybe i treat the drill to a new set and use the remaining good pulley on a jackshaft

-

Cross posting this from the lathe thread where I'd didn't attract any replies but may not have drawn the right eyes. I'm probably gonna just buy a speed controller from aliex tonight and hope but if I'm throwing my money away let me know. - Question for single phase AC motors. I have a 3/4hp single phase motor that i would quite like to be speed controllable via a knob or switch. I see you can get ac speed controllers for fairly cheap but do any of you clued up electrical folk know is they will work and work well? not looking to go single to 3phase and most of the results i get when searching for answers are to do with this. what im starting with is a farily sizable wood lathe, and am turning into a very small engineering lathe with the intention of machining soft metals and hopefully hard metals but only small parts. it has a 3" 3 jaw chuck on it to give you an idea on scale. somewhere between a watchmakers lathe and a small automotive lathe, as this that is what i want to use it for. do AC motors become easier to stall if you dial them down via the power supply over mechanically? and if so at which point does that become a problem? It has speed adjustments via belt and pulley changes but the slowest speed is still fast as fuck lol. dad picked it up for $20 cause the guy said the timber kept coming loose (throwing meter long bits of timber out at i assume mach 1 after looking at it) i need to aquire a tiny to small cross slide and either buy, or make a tail stock, so suggestions on these also welcome. also keen on a tiny 4 jaw chuck aswell

-

His sign has a vintage car on it lol

-

hmmm id heard nothing but good things about him and is pretty close to me. fired a request for a quote for timing belt on wifes new to her '13 volvo v40 - couldnt find the parts??? on volvos infamous modular motor???? that uses the same timing belt for the 4-5-6cyl variant engines????? theres a volvo dealer in town????????? pass thanks.. ill just do it myself

-

What shop?

-

If you fit a thread to the crank somehow and then use a nut welded to a socket. When the engine starts, the thread unwinds the starter nut. Or do what Martin jetpack did. 12v 1kz-te starter motor with a 24mm socket welded to the bendix. Bolt it to a meter length of steel and feed it 24v. Crouch right under the motor, hold the starter motor onto the starter dog and hit the button, with your arms braced. the throw out bendix ensures engament untill you let off the button, where it jumps back disengaged, after the 200hp 2stroke v4 hand grenade screams to life with the muffler at head height. Scary every time

-

I mean it seems fairly certain that the abs light being on is probably pretty related to the main source of vehicle speed being broken. Can't reference wheel speedy to vehicle speed without knowing vehicle speed.

-

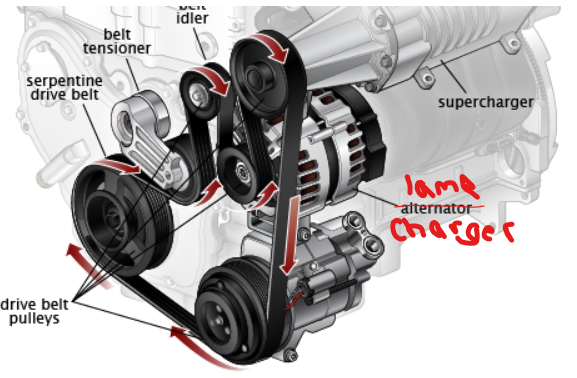

this was my first thought too. heaps of alternators have the belt kinda do like a reverse loop around them to get max wrap/traction, but then the pully spins reverse to the crank. edit - bonus points for random internet diagram including a blower. thats the problem Clint, you need to install a supercharger for it to charge. its all in the name, always has been!

-

BlownCoronas 1971 Toyota Corona

BlownCorona replied to BlownCorona's topic in Projects and Build Ups

Well i guess this marks the start of actually building this engine. Received my block back from kennally cams who gave it a quick tidy up. Not wanting to have the clean and bare block deteriorate i immediately set to coating it this weekend. Ended up settling on the the POR15 product system after reading favorable reviews. i degreased the parts i will paint and applied their metal prep (phosphoric acid + Zinc phosphate active ingredients) - meant to etch the metal and leave a zinc phosphate coating. Maintaining a wet surface for around 40 minutes before flushing and drying Infront of a heater untill bone dry. Next up was the 'Rust preventative coating' - this step was possibly not required for me but seemed recommended as a good anchor for the top coat. this coating is a moisture cured polyurethane, temp resistant and non porus coating. brushed on and left to tack off before topcoat. Finally two coats of the engine enamel. this and the above coating were also warmed up Infront of a heater to provide a better self leveling flow. First coat of topcoat black was brushed on later afternoon saturday, and the second coat went on sunday morning ensuring the first layer was properly touch dry, but not anywhere near close the 24hour recoat limit. Im very happy with the result. the above image looks wet but in reality it touch dry and had been for hours. I have a nice metalic gold for the head and front timing cover + some alloy prep. I will be having the pulleys, sump and pressed steel cover plates gold zinc plated. while not the intention, i am going for what will be a JPS looking colourway on the engine. Now that i have the block back, i can take some final measurements for the valve reliefs to be cut, then the bottom end will be balanced before final assembly.- 140 replies

-

- 21

-

-

Discuss here about Yoeddynz's little Imp project...

BlownCorona replied to yoeddynz's topic in Project Discussion

oh man thats perfect! -

Discuss here about Yoeddynz's little Imp project...

BlownCorona replied to yoeddynz's topic in Project Discussion

is there any reason why you couldn't machine a donut of lexan (or what ever appropriate material you'd use) to fit in between those flanges and just oring them? that way if the clearness deteriorates you can just put a new one in, in like 5 minutes + machine time? its possible i miss interpreted your fill level but i understood it to be around the mating surfaces of the existing flanges, so with a lens there the fill mark would be just when the oil starts to appear? would probably be nicer of the fill mark was in the middle but im sure you could rejig something to achieve that too if desired. /pour a resin donut and embed another lego man -

any recomendation for 2013 volvo v40 T5r 2.0 for the same job in chch? @GuyWithAviators do you work for toyota now? or a non specific workshop? can you source volvo/good aftermarket parts? i can and very well might do the job myself but shopping around and realised ive not used a workshop in 15 years and have no clue anymore

-

oh he also mentioned that undesirable things happen with outboard injectors and butterfly valves which likely explains that indy car setup with the butterfly way out on the end of the trumpet making its outboard injectors actually inboard. i can ask him to elaborate if you want but i don't think your going with outboard injectors anyway. i expect it probably something like dragging the fuel out of suspension when it slams into a partly closed throttle or something?

-

doing something because its cool is always valid.

-

I spoke to my friend RE roller throttles. i tried to convince him to sign up and post here lol his gut feeling was that a lot of money was spent on peoples opinions and the performance gains from rollers was never really proven (potentially if actually validated these days would show they gain nothing much). He did say that they had a massively positive response from one of the drivers who just loved the response of the double rollers, but when they really drilled down to the bottom of it, it turned out that what he actually liked and misattributed to the throttle design was the lighter throttle spring they had.

-

finally looked under the hood and saw the 4k eh?

-

space and spec constraints is probably what drove high end racing to them but better flow is not the same as more flow. Ill ask my friend when i see him monday why they were so prevailent in btcc. the only reason i started designing one is cause they look cool which is the only reason i do anything plus it was going to be a great parametric design exercise (type in what size throttle you want and the model shuffles to suit) i dont even give a fuck about performance, speed limit is the same for everyone and im too poor to go racing lol

-

Kimjon's next money pit - BMW Airhead cafe racer build

BlownCorona replied to Kimjon's topic in Two Wheels

spray that tail light in bed liner and itll look even more factory, plus be protected from UV. Gives a great cast style finish. -

a guy i work with was involved with the Primera BTCC cars and they ran double barrels, they potentially offer performance and flow increase especially at part throttle as the path is more open and much less turbulant?. as you say at WOT, less so as the butterfly becomes very aerodynamic. see the prior CFD and have a look at the pressure areas on the back of the part open butterfly. also didn't koiengsegg specifically put the freevalve tech on to increase RPM? something about much much less rotating mass in the valve train

-

oh yes i see, fuel vapour collecting due to reversion. i wonder if you could fix that with cam spec changes and/or vvti fiddling if available. going fully insane, double barrels may also fix that problem. (while also bringing several other, much worse problems). the flow increase for a barrel over a butterfly is so massive its a worthy avenue to explore. pic for others, im certain you've probably made your own charts before

-

i also have half baked cad files for a parametric barrel throttle i started to design. its something i would like to get back to as they are super sick. project stalled as i dont have a car that wants them. is there any reason why you would be injecting fuel upstream of the throttle? i cant figure out why fuel would pool on the barrel at all?

-

as you say, perhaps actually getting a satin dark grey might get you where you want?

-

i also vote no flares unless the wheels were going to fill them out about 2 - 3 inchs further than that photo. It looks (in my minds eye looking to the future) so clean with just the rx nose grafted on like factory.

-

that's not what the previous owner of my old crown thought. imagine my horror as i cruise down the central north island, Christchurch bound in a sight unseen crown that i knew had a small pulley so id i thrown a boost gauge into my carry on luggage with the thought of checking it but never did. got bored somewhere around Te Kuiti and plugged it in. 17psi so much heat it struggled to go up large hills, and when it started to rain in wellington it got substantially faster lol. thank fuck the original pully was in the boot. cool project man, I hope you figure out how to make the blower howl more, i wasn't ever able to get much