-

Posts

6781 -

Joined

-

Last visited

-

Days Won

32

Everything posted by Roman

-

Good info! Also worth noting that brand new R154s are available at a decent price from North Shore Toyota parts department, when they started selling them over the last year or two it started pushing down second hand prices as people just buy new instead. (They are somewhere just under or over 3k brand new from memory)

-

The poor man pays twice! I have learned this lesson the hard way soooo many times hahaha (and continue to try and be cheap)

- 39 replies

-

- 3

-

-

- avenger

- more speeds

-

(and 3 more)

Tagged with:

-

The completely opposite way to approach this situation, is to come up with your theoretically ideal gearbox and diff ratio first... and then see what options match. Soo... What engine speeds do you want to keep between? Looks like change gear at 7500rpm to land at 5000rpm would be good. 7500 / 5000 = 1.5 So for this, you need the following ratios if you have 1:1 as 4th gear: 1st: 3.375 2nd: 2.25:1 3rd: 1.5:1 4th: 1:1 5th: 0.66 Then you can put this info into here http://www.apexgarage.com/tech/gear_ratios.shtml and tweak your diff ratio up and down until you get near your max speed target hopefully with an available diff ratio. If you dont have any easily available diff ratio options then it's all the more critical to choose your gearbox correctly, as gearbox ratios and tyre size are the only ways to adjust this. You'll notice that real life gearboxes dont have the same ratio of rpm drop between the gears, this is usually because each gear has a different "task" Like 1st gear might be optimised to get the car off the line easily at the lights, 5th gear might be to give a 3000rpm cruising speed, and 2nd/3rd/4th have ratios with accelleration in mind. Using that calculator above, you can adjust rpm up and down to see what speeds you will be doing in each gear etc etc so you dont end up nanging at 5000rpm when trying to trundle down the motorway in top gear. You might find that a change of diff ratio helps you acheive what you're wanting just as well as a different box would. I have a 6 speed box and I only ever use 4 of the gears on track, this covers ~60kph through to 190+ If you've got ~90hp you're going to max out at probably 140-150kph at Hampton or Taupo full track so all the more reason why (an appropriately ratio'd) 4 speed box is fine for racing.

- 39 replies

-

- 2

-

-

-

- avenger

- more speeds

-

(and 3 more)

Tagged with:

-

OS drags is coming up rapidly so I thought I'd better swap out this rattly gearbox. I got it all swapped over easy enough, and then I thought I'd wire in a MAF sensor again at the same time, as well as an exhaust pressure sensor. And then things escalated and now all of the car's interior is back out hahaha. But MAF/exhaust pressure sensors will give some interesting insights into tuning VVTI angle at part throttle for best economy. When using the MAP sensor as the load axis for the tune, advancing the cam gives strange results. When you advance the cam enough that you start getting overlap, since the manifold is low pressure and the exhaust is higher pressure, you get some of the exhaust gas coming back through into the intake manifold, before it gets sucked back into the cylinder again as the piston starts to go down. This means that the measured MAP pressure goes up, (By 60% in one case!) so the engine adds fuel and pulls ignition timing. Which is the opposite of what you want to do when youve got EGR gas in there. So you need to redo these two things each time you change the cam angle, which isn't really practical. So I'm going to set MAF as load source for these tests instead, as it will stay more constant and wont be measuring the "dead" air from the exhaust which has no oxygen in it anymore. Since I need a MAF to do some testing, which means I cant use my airbox thingy for the moment I'm gonna experiment with something else as well. I saw an article where someone had varying results by tuning the length of the intake pipe ahead of throttle body. Presumably by making it a tuned length for reflecting waves back down the pipe. So I'm gonna start with the longest pipe I can fit and then slowly cut it down more and more and see if fuel requirements change at all. It's also handy having a long straight pipe for best MAF readings as well, while I am testing this. To be honest I've got no idea whether this is going to be any better or worse, at any length. But it'll be interesting to see if there are any noticable harmonics happening in this first part of the pipe. If not, it just confirms my previous idea that aiming for maximum mass flow is better than having a tuned length. (as per airbox thingy) Either way, one or the other is gonna get thrown in the bin and I'm all about that!

-

T50 is an AE86 gearbox, so that puts you into the highest Toyota Tax bracket possible. So like 8000% tax according to this muppet: https://www.trademe.co.nz/motors/car-parts-accessories/toyota/gear-boxes/auction-1460390328.htm But more realistically even a non desirable bellhousing / spline count version from a different type of car is likely $500+ these days. For a flogged out 30 year old heap of shit with 300,000kms on it. Do not want. (They are a nice gearbox when in good condition, just not cheap anymore)

- 39 replies

-

- 1

-

-

- avenger

- more speeds

-

(and 3 more)

Tagged with:

-

Auckland Monthly Meet - Wednesday 22nd November

Roman replied to Threeonthetree's topic in Upper North Island Region

I'll be there! Ahhh.... Maybe.... -

Depends on ECU or whatever you're using, with Link you can only go to a max of 500hz on digital inputs, so usually ABS rings need to be cut down to every 2nd tooth or whatever. I've heard people having 4 points per rotation and working well enough. I've also seen reccomened that for something like wheel speed sensors for launch control where wheel speed is low, you'll want to avoid using reluctors as the output voltage can be too low at low wheel speed. Also need to keep in mind that some traction control strategies compare driven wheel speed to non driven wheel speed, which doesnt work if your front wheels are in the air which will hopefully be the case You can get a CAN based 20hz GPS unit that can input speed into ECU designed for motorsports applications, GPS speed might be a good way to view speed when front/rear wheel speed ratio becomes unreliable (due to tyre expansion, front wheels off the ground, wheel spin, etc) plus would be a good thing to have in datalogs regardless.

-

Well on the positive side, a 4AGE dies every time someone steals their throttles for something else

-

Surely putting SR20 ITBs onto an SR20 is not the most challenging conversion though

-

Andy Wyatt does a good video on idle control theory.

-

I have a dedicated barometer in the ECU already and a MAP sensor on the intake, so I can look at any combination of these three things as well as MAF readings. Some ECUs, like the latest Adaptronic one. Instead of having an onboard barometer it has inlet MAP and exhaust MAP sensors. Then part of the calculation for the load axis is the pressure ratio between intake and exhaust. Apparently this allows for changes in altitude etc better than any other system. I've found that when I advance the inlet cam at low load, to introduce overlap.... MAP pressure goes up for same throttle angle. At one point went up 60% higher because of EGR effect blowing exhaust back into the inlet. So its hard to tell which cam setting is more economical, because when you advance the cam it pulls all of your ignition timing out. When it should add it instead. MAF will be a better load axis for setting this up initially. So this is where exhaust/inlet pressure ratio would be interesting to look at. It will be interesting to see if there are noticable peaks and troughs in the exhaust manifold pressure from the tuned lengths of the pipes like you do on the intake side. I think a combination of MAF / MAP / exhaust MAP will tell an interesting story for deciding on cam settings at partial load. Lately for 4000rpm+ I have had all load cells with the same cam timing as full throttle. Which I think has helped with snappyness of throttle response as the cam doesnt need to "catch up" when you put your foot down... But now I've noticed a lot of fuel or oil in my intake manifold when it's previously never been an issue. So I think when inlet valve first opens with that much overlap at low load, it's blowing fuel back up the intake runner and into the plenum.

-

Has anyone here setup an exhaust pressure sensor before? Looking at OEM setups for diesel differential pressure sensors, they have a fairly short stainless steel pipe connecting to the exhaust, and then a length of rubber(?) hose going to the sensor mounted remotely. But perhaps these are more resilient to heat than the map sensor I'm going to use. Or maybe diesel exhaust gas isnt as hot? I'll be expecting EGTs of maybe 600-800 deg? So needs to cool the gas quite a bit. Damn I wish I still had my thermal camera haha. Have been advised using copper pipe is a good plan for dissipating the heat, but then what after that? Would silicone hose be okay?

-

Auckland Monthly Meet - Wednesday 18th October

Roman replied to Threeonthetree's topic in Upper North Island Region

Oh no the wof has run out on my car! Guess I'd better come along anyway. -

Hyperblade's KP61 Racecar "KP61R" Discussion

Roman replied to Hyperblade's topic in Project Discussion

Cool to see this all finished and in action! How do you find your dash, in terms of latency / lagginess? -

You replaced the wheel bearing six times before thinking perhaps it's not the wheel bearing? hahaha just giving you shit but thats pretty funny

-

Interesting article on pipe length / power differences http://www.autospeed.com.au/cms/article.html?&A=107749

-

Hey @Celica RA45 here's a question... Since the manual engines run TI valves which are obviously lighter, does this mean they run a softer valve spring as well? Compared to auto engine with steel valves.

-

Yeah well its been proven to work by others, its also possible that it just wasnt fuelling evenly between cylinders on mine as the runners arent exactly the same. But either way, in my case the benefits werent worth the downsides. Also if you have a quad throttle setup where it's at the same temperature as the head then you'll probably have a better result as the fuel evaporates a lot quicker. Something interesting, I saw someone post a factory inlet manifold for an SR16VE N1 and it has staged injection from factory. The other 4 injectors are in the head.

-

Great progress lately Tom! Keep it up.

-

Okay soooooooo as awesome as it was living in a beautiful place and having a cool Automotive related job, life in Cromwell/Queenstown wasnt quite right for me. It was awesome fun working at HPA, made some friends and great memories which will last a long time. But, it just didnt quite feel like somewhere I wanted to settle down and in some ways it wasnt the career direction I wanted to take. So for a variety of reasons I ended up coming back up to Auckland. Being landlocked so many hours away from the ocean just didnt feel right! It was a bloody awesome experience though and it felt like it reinvigorated my life and got me back on track after some hard times lately. But anyway! It was good that I never got to the point of attempting to drive the Carina down, as the new driveshaft combination wasnt good. It took a bunch more mucking around after I got back to get this right again. But sadly it looks like the previous incident may have stuffed the bearings in the gearbox as it's pretty noisy now and leaks fluid out the rear main seal even after replacing it. Pooz. But it was great to get back home and be able to go drive it around again! The R888s are on my normal wheels so I've been driving around with a 15x6 running 205/50/15 and have noticed no negative effects to handling. Possibly because the sidewall of the AD08R is so stiff. Since I've been back, I started with a fresh sheet of paper on the tune file in the ECU. As it had some old junk in there, as well as some stuff that I setup when I ahhhh knew less than I do haha. The staged injection seemed to work well enough in terms of delivering the right amount of fuel and blah blah... But it was always a bit crappy in transient conditions. I decided I would turn on the outer injectors 100% of the time and try tune the car using just those, and get the accel enrichment and so on working as best I could. But it just felt boggy. When I reverted back to 100% inboard instead, holy moly the throttle response difference was amazing. And so the pull out of corners was much better and it felt like you could more accurately mash the gas and know what the car was going to do. So I ditched it and put a standard manifold back on. My theory is that since my intake manifold is thermally isolated from the head, it is not able to use the heat of the runner walls to evaporate the fuel so you have massive fuel pooling issues... Which means you lose control of your fuelling as some fuel you squirted in several cycles ago is only just entering the combustion chamber as it evaporates. So fuel you add at say 5800rpm only enters the cylinder by the time you get to 6000rpm and so on. And so if you tune your car with the acceleration rate of say 3rd gear fuelling isnt right for 1st gear anymore. Just lots of headaches that you cant really address well enough with the accel enrichment available on a G4+ In the documentation from Toyota on their wall wetting experiments they note that on a cold port (engine cold starts) fuel can take over 1.5 seconds to evaporate and contribute back to fuel in the engine so even if it was only half as long on the runner walls. It's a massive surface area covered in fuel which is always going to be a ball ache to compensate for. Going back to a standard manifold looks to have cured a vaccum leak or two as well, haha so the idle and so on is much better too. I've been playing around a bit with a few variables such as injection timing and VVTI advance as well. I have found that changing the injector timing so it's injecting fuel as the intake valve is open helps a lot with cold starts, and results in a lower fuel consumption when the engine is hot too. Since it's been cold I've also spent a bunch of time getting the cold idle really nice, closed loop lambda adjustment works really well if you set the adjustment rate to 1hz so its only slowly adjusting it. Otherwise it makes the idle surge if you try to run closed loop at say 20hz like you could if you were doing 4000rpm or whatever. Under cruising conditions it seems that advancing the intake cam at all just means worse economy. This may relate to the tuned length of the primaries and secondaries of the exhaust causing some undesirable something something at cruising rpm compared to a standard exhaust manifold... But for whatever reason, it isnt beneficial to advance the cam. And at high rpm low load, rather than retarding the cam I figure I may as well keep the cam advanced so when you stab your foot back on the throttle the cam is not having to "catch up". And this seems to have made the throttle response even better as well. So the engine response is better than ever! I picked up a cheap Altezza engine, planning to give it a freshen up and at some point swap it over. I'll be losing the fancy ported head of my current engine, but will be gaining: -Exhaust side VVTI -Higher compression ratio -better alternator position -Better water line setup -Better engine mount setup -Better PCV valve arrangement -And a few other minor advantages so I think it's worth the trade but will be interesting to see. The state of the oil and colour of the coolant in the altezza engine though is bloody disgusting though so it'll need a strip down and hot tanking or whatever before doing anything with it. So might be a while until it's ready to swap in. But looking forward to having a play with the exhaust side VVTI. I think I'll wire in an exhaust pressure sensor when I do an overhaul of the loom to suit some of the changes needed. Will be interesting if this will show anything relating to tuned lengths of the primary and secondary pipes. In the immediate future however I'm just really enjoying living at the start of Scenic Drive in Titirangi now and being able to go for some awesome drives on some backroads making doort noises again

- 165 replies

-

- 37

-

-

Sorry but yeah this is a sign that your engine is completely dead.

-

Haha never seen a bucket failure before at all... Then just saw this on FB today.

-

WTF thats weird about the bucket! I'd almost think that perhaps the bucket got stuck and valve pushed into it from underneath? Will be interesting to see what it looks like under the bucket? I've got a spare head here with some buckets if you need them.

-

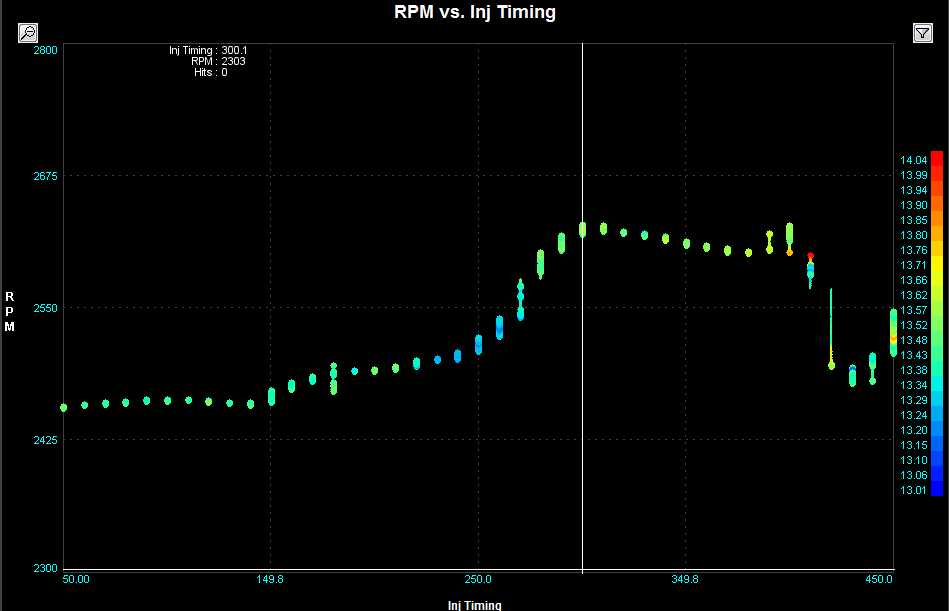

I've had some interesting results with injection timing at idle, and a friend found that with E85 cold starts became much better with approx 250 degrees BTDC end of injection for timing. Rather than 400deg default setting which fires fuel before valve opens. So I thought I'd try something else at a higher rpm and low load. With the car bonnet up, oil cooler fan on and radiator fan on to try stabilise conditions. I used the e-throttle to increase minimum throttle position the engine sat at 2500rpm and at the goal AFR. Then I iteratively increased the injection timing from 0 degrees through to about 550. I wasnt able to control ever variable here as when the rpm changes slightly it interpolates the ignition timing and fuelling slightly. But it was interesting to see that changing the injection timing alone caused a very clear pattern here. As for interpreting the results however, Dont know. Maybe higher rpm for same mass of air = more power / better air fuel mix? My best results at idle were around the 220deg mark, but I'm guessing ~300 looks best here unless anyone has any other thoughts.