-

Posts

14,713 -

Joined

-

Last visited

-

Days Won

10

Everything posted by Raizer

-

Random slightly cool stuff you built but not worth its own thread, thread

Raizer replied to h4nd's topic in Other Projects

@chris r, @UTERUS, @GuyWithAviators etc all said the same, @Shakotom said that's illegal though. /Prob going out the side tbh, neighbors shitty Bongo has a side pipe and gets WOFs so should be fine ha! //Main concern is I can't afford to lose ground clearance with some of the fields I end up in often. So committed to a MIG Remembered I don't know how to use a MIG so kept at it with my little TIG Should flow a touch better?! Took several attempts to get it to here, but it clears the bell housing, shift linkages and trans cooler lines so it'll be mint now. Grinder and paint make me the welder I ain't or something Embarrassingly I forgot to pick up some straight tube on Friday, so it's going to be a rather loud trip to the steel shop in the morning! -

Been kicking the tires of a few MIGs lately, mentioned to a customer of mine that I was in the market for a mig and asked what he would recommend on a minimal budget (he's a welding teacher at EIT), told me to go to BOC and check out the new Raptor ones and to name drop him. So yeah, this happened Chucked in a free 5kg wire and a pack of tips and also knocked close to $200 off the already discounted price!! Bunnings trip for some gas and I'm pretty much ready to make a mess of some steel ha! *fuck I need to give the old van a clean out one day soon*

- 764 replies

-

- 13

-

-

Random slightly cool stuff you built but not worth its own thread, thread

Raizer replied to h4nd's topic in Other Projects

Yeah it's not too bad access wise, still a bit of a pain getting at the top bolts on the turbo, could be super easy if I took the rear carpet out and pulled the bell housing cover though. It's going over the swaybar + diff + Panhard then snaking around the spare wheel and diesel tank etc that's looking like it'll be the real challenge for me tbh, especially considering I'm using a lift tig on a gravel driveway ha 2.4 petrol version for reference. -

Random slightly cool stuff you built but not worth its own thread, thread

Raizer replied to h4nd's topic in Other Projects

Tungstens acquired, still figuring out what I'm looking at with migs so am holding off for right now. -

Random slightly cool stuff you built but not worth its own thread, thread

Raizer replied to h4nd's topic in Other Projects

It's only taken close to 18 months, but I've picked up where @chris r left off (failed flexi and upcoming WOF made me get off my ass and into the shed) It would have helped if Chris had the van on hand when he started, we would have known it was wanting to go straight through the shift linkage then haha! Figured out the patch needed with CAD Can't find the pack of tungstens I've got in a safe place, so that's as far as I got, will grab some (or a MIG welder...) tomorrow. That's with the stock on still in place, should have tons of clearance from the shifter when it's actually bolted up! Just need to order a 45 or 60 and another 90 to finish it up, might get fancy and throw a V band in there while I'm at it. Inspo from another Super Custom fan: -

Maybe wide body 200 series HiAce? Even the 2wd 200s are 6 stud from memory.

-

Good thinking re the ecu, mine had several popped caps which had melted a few traces on the board. Still ran but the trans wouldn't give 1st gear in drive and randomly drop out of overdrive, also went into limp mode at times.

-

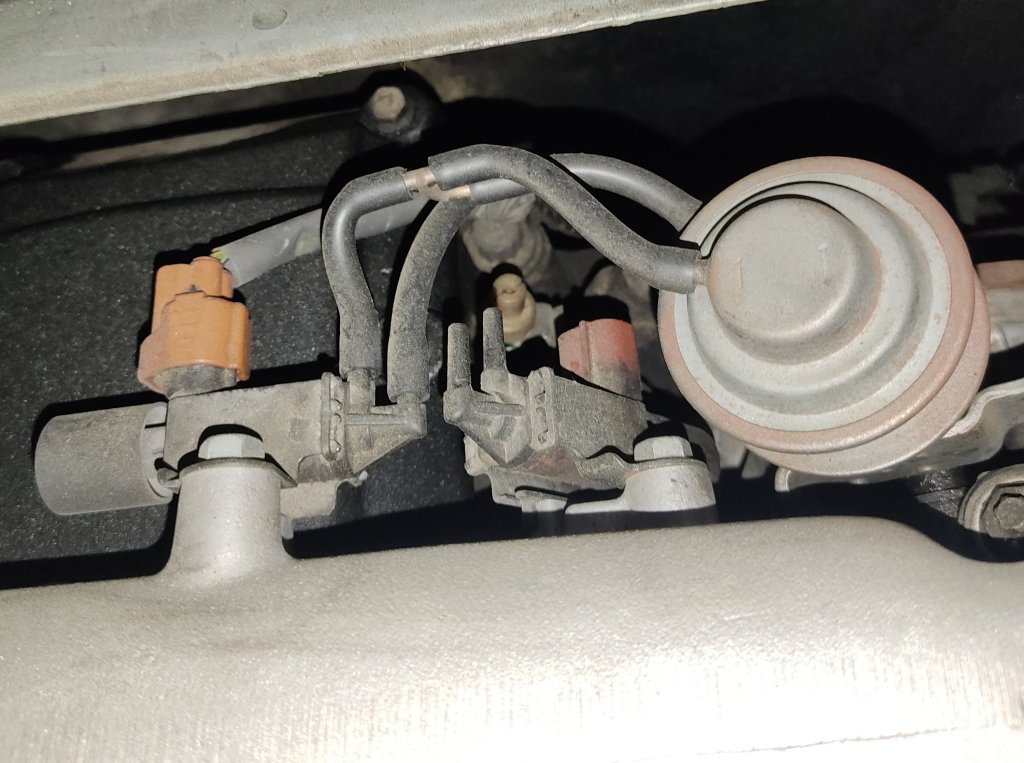

Twin butterfly throttlebody in these older 1kz negates that a lot, the smaller blade is normally wide open. The vacuum pot is for closing it, one of the ports closes it a bit over half way when the EGR is open and then the second port is to pull it the rest of the way shut for soft shutdown.

-

Oh yeah, dunno if it differs across models etc but I found if I fully removed EGR the ECU got a bit unhappy and would throw up a CEL and go into limp mode So I've got the vacuum solenoid plugged in and cable tied out of the way in the engine bay, doesn't need vacuum hooked up just the electrical side of things.

-

T the 2 vacuum pots together, hook up to the solenoid valve that opens when the key is off. Remind me in an hour and I can take pics of how I did it in my KZH

-

Eastcapescapade 2021 November 12th, 13th, 14th

Raizer replied to johnnyfive's topic in Upper North Island Region

He's down there, you should kidnap him and bring him up 2-up on your posty -

Any garage, hold is taken off when you buy rego. VTNZ for pink/green sticker removal.

-

-

Your pics aren't working, Google photos isn't a host for sharing.

-

Think it was @Truenotch that put me onto these ones. https://www.trademe.co.nz/a/marketplace/business-farming-industry/industrial/manufacturing-metalwork/helmets-safety-gear/listing/3303528436 that's around half recommended retail too. I've been impressed with mine, I'm no expert but it's way better than my 3M one I paid twice as much for.

-

I was with boc, but wasn't using enough for the D plan to be worthwhile. Bunnings still seems to be the go from what I've seen, at least for me barely using a D bottle every year or more.

-

Sounds like the factory alarm being a dick. All doors/bonnet shut properly?

-

They are belt driven

-

Plan B, PGO, Daelim, one of the other Gyros are all CVT and would happily thrash off-road without giving a fuck lol. /I'm not phased either way tbh, if I was coming I'd likely just bring the H100 anyway.

-

They just don't want their Lifeless 125s getting smoked by 50 and 70cc CVTs

-

Yeah good point about the bell housing cover, unsure if it'll bolt into a a tradie Hiace without trimming the floor back a bit. Super Custom (1KZ at least) has the same engine bay and covers as the factory 1UZ ambulance.

-

Or start with a Super Custom/possibly just use Super Custom engine covers

.jpeg.4c4ad7c7cf73a08342c2adbc3949f467.jpeg)