-

Posts

3374 -

Joined

-

Last visited

-

Days Won

1

Everything posted by NickJ

-

I'm out of town that weekend but want to express admiration for this initiative, big thumbs up

-

Random slightly cool stuff you built but not worth its own thread, thread

NickJ replied to h4nd's topic in Other Projects

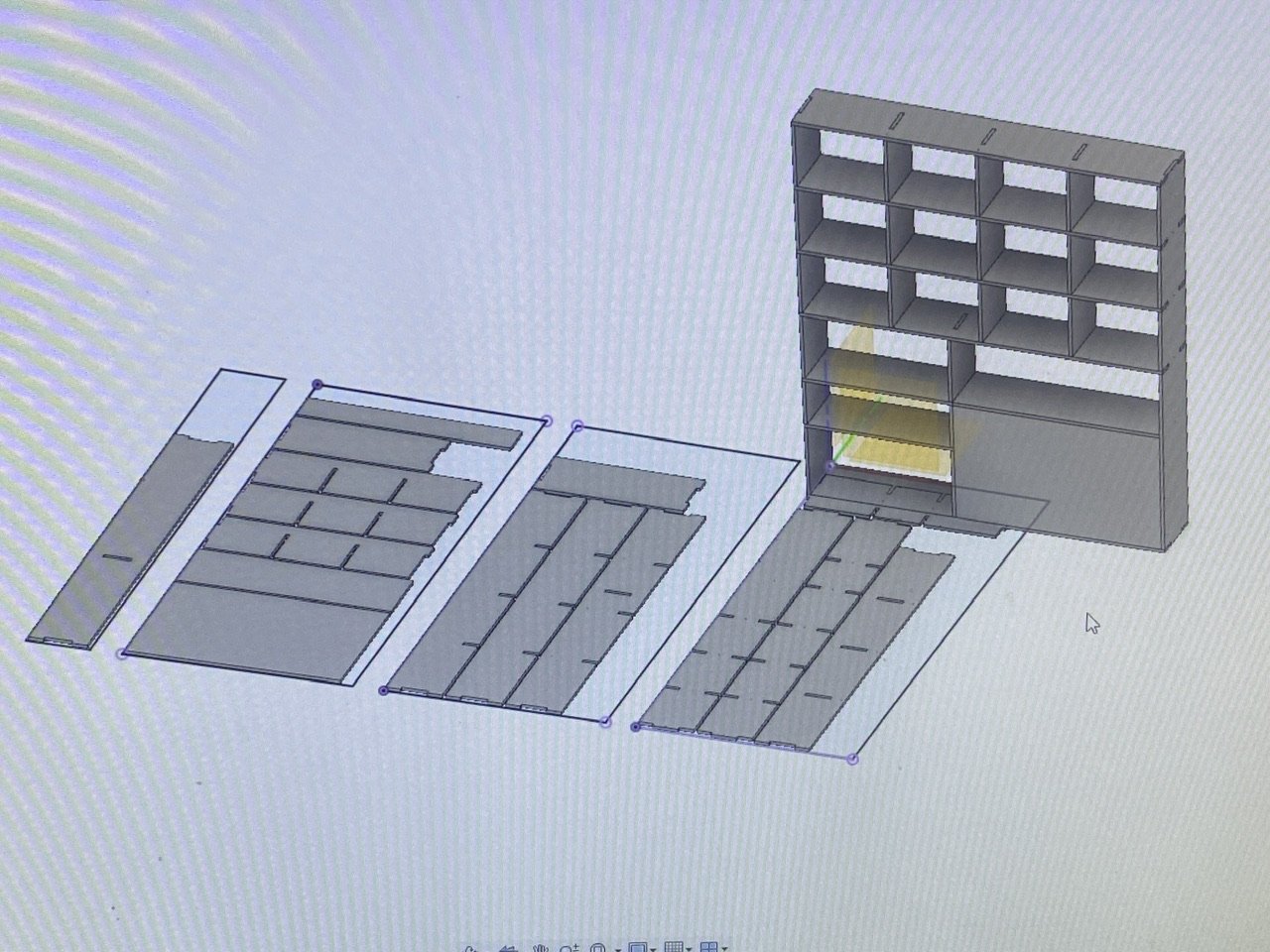

Thats a sweet shelf and suits the room, no way I could have filled the design brief with the hand tools I own, fortunately cnc makes me the carpenter i’m not. Machine is now set up to take a full sheet of ply however the geometry doesn’t allow the spindle to traverse the full 1240mm. Have you had a play with the arrange tool? Quite handy for working out nesting from available stock and then makes machining simple (aka all delays are very much self inflicted) -

Random slightly cool stuff you built but not worth its own thread, thread

NickJ replied to h4nd's topic in Other Projects

Hey man, client's design, I just machine to drawing.- 1289 replies

-

- 12

-

-

-

-

Random slightly cool stuff you built but not worth its own thread, thread

NickJ replied to h4nd's topic in Other Projects

GF wanted some fancy shelves in the lounge, she timed asking just right on the same day as I was getting the cnc running again. A day of design, three sheets of ply and press the green button. Slot together and a few screws to be sure.- 1289 replies

-

- 29

-

-

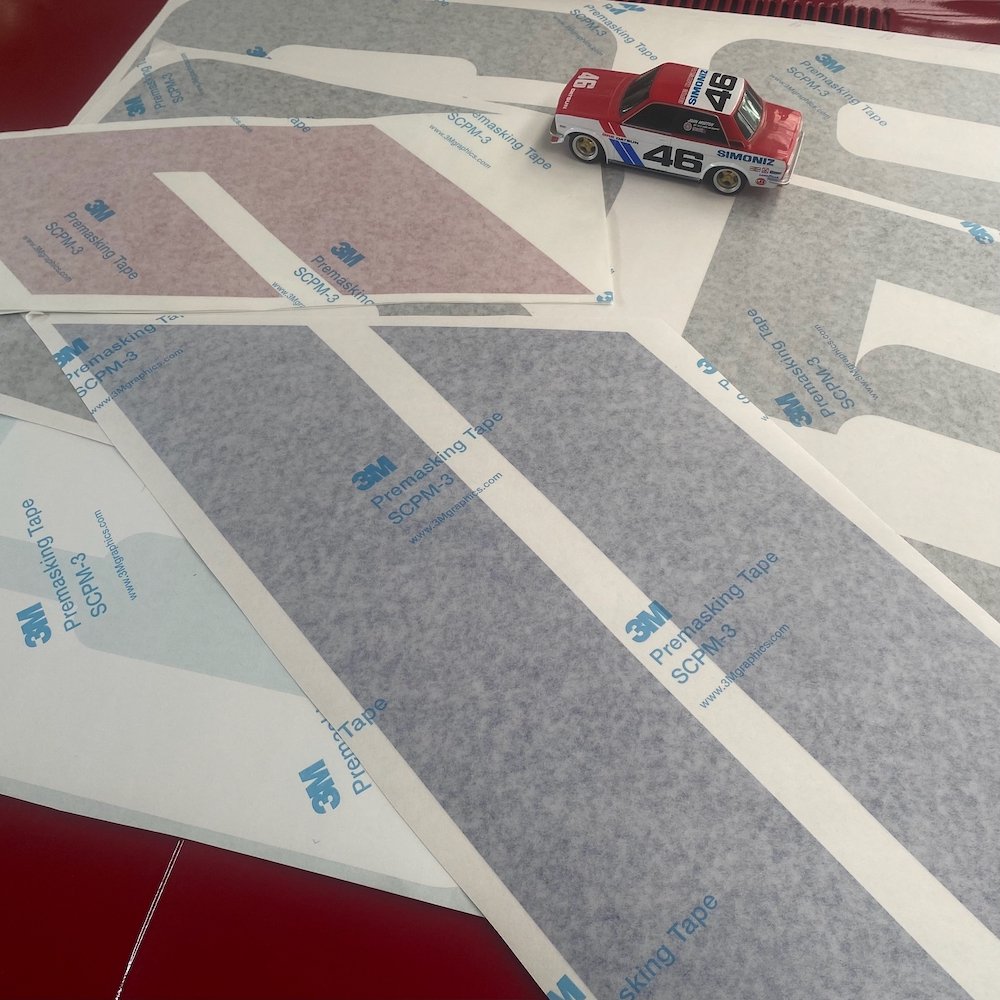

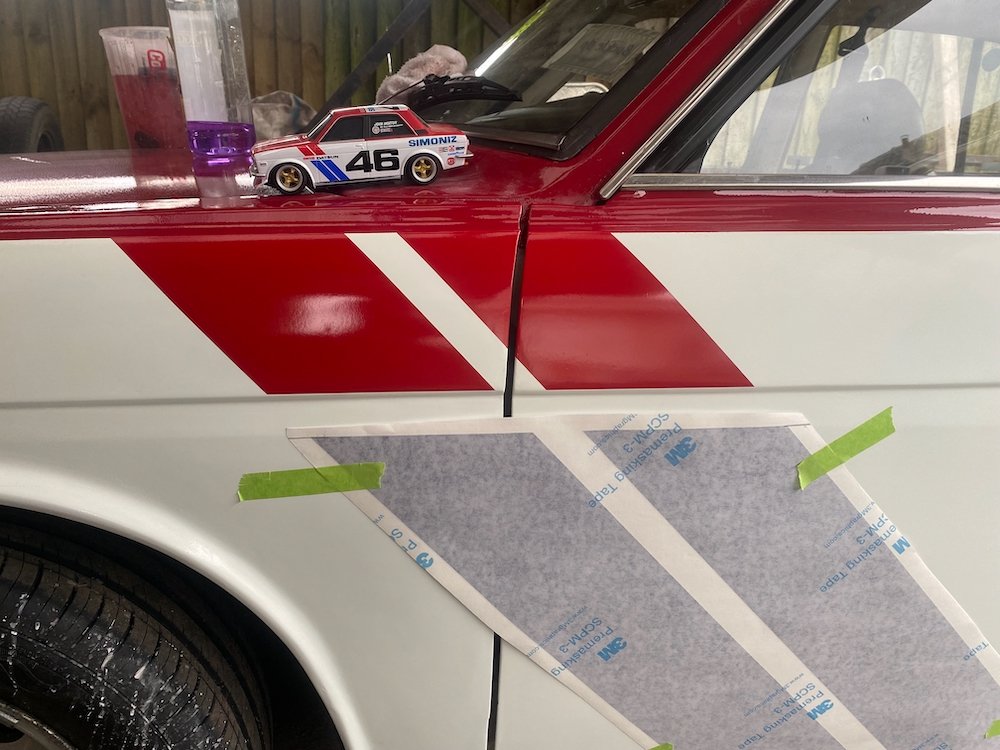

Yeah/nah the wof man aint gunna like that so the 20 year anniversary of these tyres will be their last Much nicer although they do feel softer...... Postie was feeling generous and delivered a roll of fun, had to dig out an old toy to approve the design Approval gained after a thorough wet sand to hide the painter I am not, quite an enjoyable task with the current temperature reaching for 30 odd. During a test run I found the hi beams not quite up to task, this lead to unwrapping the loom to trace the aftermarket relays, somehow a few of the connections had been messed up and along with the ever present dodgy fusebox had left me chasing the wrong issue. After a few pages in the 1B5 to figure out the circuit, its all back together and selecting the correct beam. For added bonus the high beam relay is no longer a parasitic load, hooray!

- 53 replies

-

- 31

-

-

3d scan and bend for that price is a steal, its not so easy nor quick, so often its seen as the perfect repro method, but it has its limits and needs full understanding of all the variables to execute right, rough workflow Prepare part for scanning Scan the part Import file Rebuild in CAD using start & finish as guide Add bends to match available dies Adjust for best fit Export Bend Recheck If ol mate murphy didn't visit (he always does) Adjust file Rebend Job done, but at $100/hr for the skilled labour + scanner + software etc etc, you don't get much time to make a buck. After all that, errors are often present, but after a few iterations you figure it out and then can go onto CNC bending hundreds of copies. In saying that, if thats what they sold you on, you'd expect they had the workflow down to deliver, from the photos it looks like the forward pipe needed a lazy bend to sit inside but the machine could only do a tight bend putting the two into the same space, rather unfortunate.

-

-

Ended up getting a commercial glass fitter mate over for a second set of hands, we wound up making some tools from 0.6mm stainless steel to pry the gap open as the other person fed the trim in. Got 99% in using straight dish soap, made a mess, corners are almost impossible. Still managed to tear a small section, thankfully under the trim.

-

Nah, not quite unfortunately, thats a different profile, had plenty of people say the same tool, this trim holds by one side only and the trim isn’t flexible.

-

So how does this trim on the Datsun go in? if I fit the trim to the rubber first it comes out fitting to the window. fit the rubber to the window then I can’t get any useful tool in to lift the rubber to fit the trim. Kinda stuck, but somehow they got it in the factory? Or recommendations for an oldschool glass fitter in chch?

-

The wof to do list has now become pretty trivial, starts, runs and stops just as good as I remember, for added benefit all mechanicals and electrics operate as intended too. Paranoia was weighing hard during the quick run up our street but the only issue of note is some guard rub that will be an easy trim to fix Still quite a few jobs to get it how I want it, but i've gained most of my shed space back With f-all mechanical jobs left and the wof stuck waiting on the postie for window seals, I hooked into the cosmetics...... Cos i'm no painter there was a bit of orange peel to deal to, started wet sanding the car today and made an absolute mess, thankfully youtube came to the rescue and after adjusting my technique moved through to 2000grit before polishing up the last bit. While i could go further, i'm really happy with the finish, not gleaming show car perfection but a finish as you'd expect from a car of the 70s. Just the roof took a few hours today so looks like it will be a few days before the whole car is done.

- 53 replies

-

- 31

-

-

Non branded and likely came from toolshed or similar, I find it doesn't get the velocity at the tip to atomise nicely and when I ramped the pressure up to compensate it really didn't like it.

-

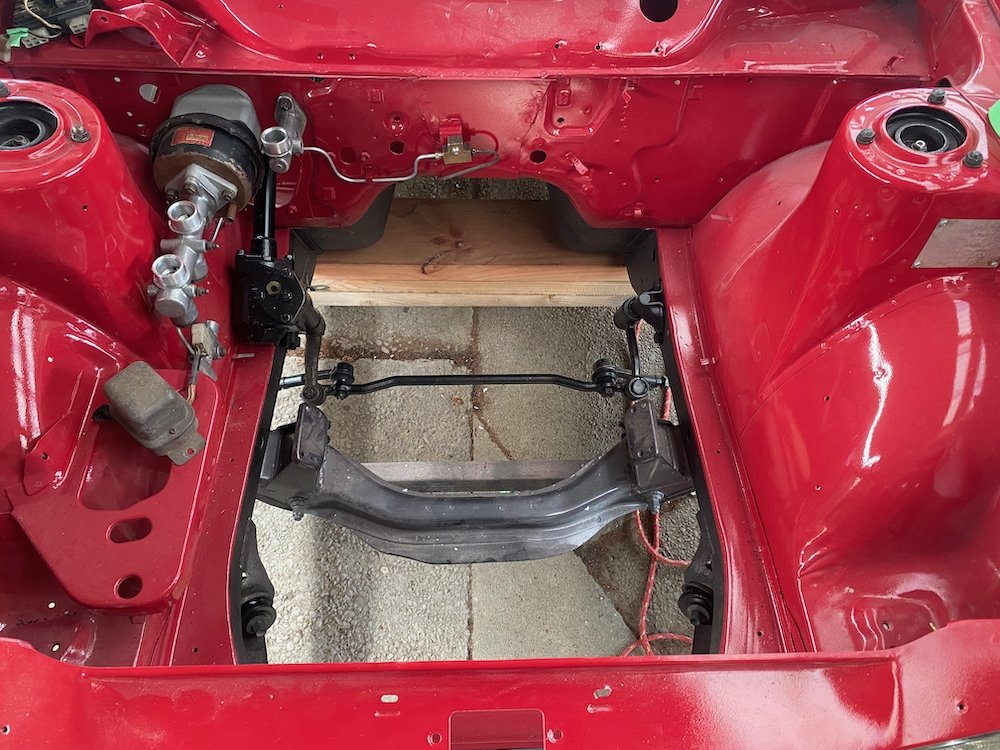

Well, ahhh Yup Last few weekends have been motivation central, brake lines bled, engine, transmission, driveshaft in, fuel tank and lines etc etc. With pretty much everything together I poured in some fresh gas and after leak checking the system turned the key all the way..... Would love to say it fired right up but the points had corroded just enough, a quick tickle later and the engine fired straight back to a steady idle as I remember. Only thing stopping it going for a drive now is fluids in the gearbox and diff. Plus some minor things such as seats not bolted in and I need to source a rear windscreen rubber, simple right?

- 53 replies

-

- 28

-

-

I have a cheap one, its crap. good for primer thats gunna get a sand or motivation to purchase a nicer gun

-

Still at it, progress is steady with visual changes becoming more obvious. Finished off paint around the window frames and fitted the doors, still need to fine tune the door gaps Finished off all the brake lines including the left rear that I wasn't too happy with. Managed to find new seals for the front calipers, they are ready to bolt back on Had a go at the interior too, while i'd really like to drop it off and have someone do the whole lot super nice, there is not much cash left in the tank, sourcing some nice fabric I repaired all the pillar trims that were ripped so that the windscreens could be fitted, the roof lining looks even worse up against fresh cloth! Few more weekends at this rate should get the engine in the hole before Christmas

- 53 replies

-

- 24

-

-

Still plugging away, winters been a bitch, weekends haven't gone to plan and the cold weather makes opening up the workshop a pain. And then when the weather did play nice, of course I had to keep up with house renos, at least I could outsource some of the work to the cnc and click through lighter work such as tending to the chrome. This week I started fitting out the engine bay, original brake booster, master cylinder, steering gear and pedalbox, new tie rods thanks to Rockauto, coat of black paint for pretty much everything else. Front struts and hubs complete with new bearings are in, same as the rear, at this stage keeping the same shocks all around, have a few things to work out before confirming what way to go. Wheels go on, dolly comes out Good to see those eyes on their feet again! Valance is pretty messed up, made the call during paining that i'd repair but not get too worried about shape as its ultimately hidden behind the bumper, hopefully a longer term plan will eventually sort it out. Have been renewing all the brake hard lines as I go, after putting the suspension in I found an issue, brain fart while bending the left rear I had the arm upside down on the bench, thinking I had more space the turn to get to the union hangs pretty low, best replace this one before going to far.

- 53 replies

-

- 26

-

-

One vote for toss it all in the fire and start again. Those fuses give me nightmares.

-

Mid 90s car, easy as, beyond that it comes down to the individual vehicle due to mind numbing complex methods used to make a lever move up and down, the information is usually out there as to what wire is hidden where.

-

Water is roughly 0.5psi/foot of depth, if you ran a compressed air line to the tank on a warm day, an outlet into a suitable column of water will give you a very accurate pressure. A rubber glove taped over a pipe also makes a suitable low pressure relief valve just don't ask for ASME certification. In all seriousness, large pressurised volumes are why certain regulations exist, tread carefully (or go full Wile E Coyote)

-

Did I drop some off to you when we electro-nerded in the sun ages ago? I'll recheck my stocks anyway

-

I have plenty of 4cyl starters here, can take pictures/part #s if that helps?

-

Don't you mean complex pipework and valves to divert gas flow to a single sensor?

-

If you have confidence in the system, one bank is fine and swap to the other just to confirm. Or temp sensors on both sides that will give relative conditions for cheap on initial start if it is that important you need both banks for tuning, then really all cylinders should be monitored.

-

Kinda yes, there seems to be no widespread industry standard for V band clamps, i've found plenty of variance in both size and contour from different suppliers additionally some size off the band, some off the tube.