-

Posts

3,958 -

Joined

-

Last visited

-

Days Won

1

Content Type

Forums

Downloads

Events

Gallery

Everything posted by NickJ

-

Keen to hear how you find that machine, sounds pretty useful in the vid

-

What sort of buy in cost is required for a newb to attend? Bike experience limited to AG100 on the farm. Bike + safety gear = ?

-

Tried all those, some are repeats, no further progress I can get into the "Shared folder" but not the local user folder. I can share folders within the local user folder and see them on another computer, but not open them, comes back as location not found.

-

oooh, there are some moves there I have not tried!

-

Weekend at Barrys

-

Put me down as keen, happy to get involved changing tyres/brewing coffee

-

Is it not up to the lines company to maintain infrastructure?

-

Sounded good to start with, but no luck. This is getting close to being so simple, so simple that it will be embarrassing.

-

Sounds about right, keen to hear if you remember anything, so far following internet guides and AI have gotten nowhere that even some new search terms would be good

-

You would be very welcome, bonus points if you park a period correct Telecom Sierra out front

-

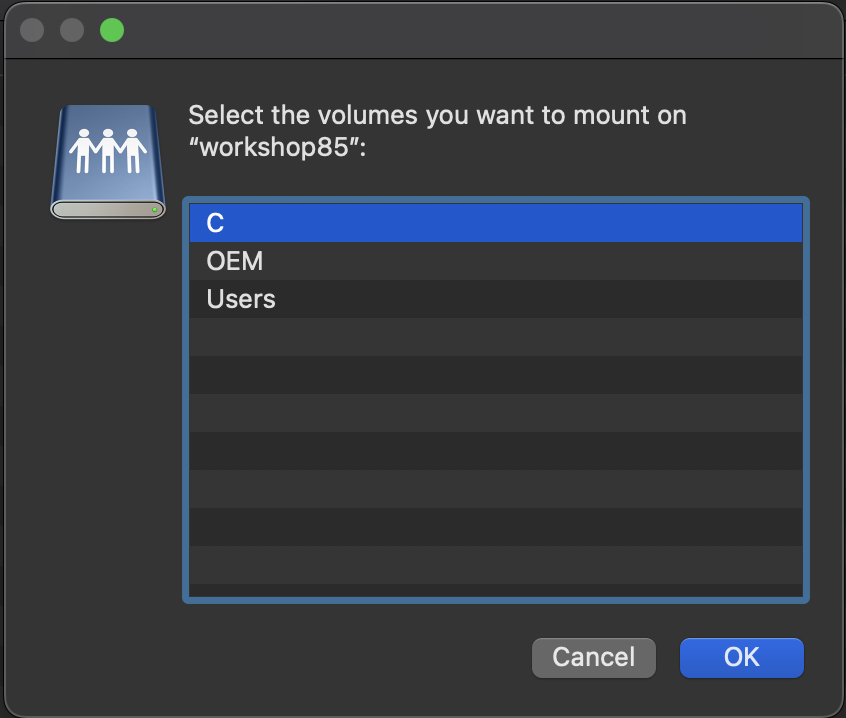

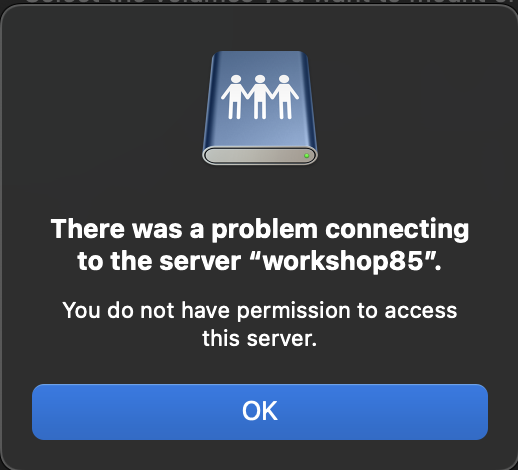

I can get this far I got "C" and "OEM" to show in that list by right click/properties/share but as soon as I select them it gives this Password sharing is turned off, so is the firewall, and on 40-56bit encryption, 128 didn't show at all. My linux computer has exactly the problem, can see the windows machine but thats all

-

Correct, I can get folders to appear like that, but as soon as I try to open them it says I don’t have permission or it can no longer find them. I have changed all the permissions at every level to allowed, no change

-

Anyone here know the secret sauce to get windows 10 to allow network access to more than the public folder?

-

Getting my feet wet learning the inner workings of Linux and Windows, managed to network the workshop PC and CNC, no more memory sticks to transfer gcode, just post direct to the machine. Pretty good for a Tuesday

-

Actually, this weeks tech winner award goes to a large player in international shipping Had to fill out a mass of forms, by hand to dispatch items, obviously the way to avoid this is via the online portal, fair enough if not that their system requires 2FA to login, notifications which are sent to somewhere in accounts. How TF did someone come to the conclusion that 2FA should be applicable to business accounts?

-

They seem to be enjoying daily pop ups in teams asking me to try all the new features. Also love Bing randomly deciding i'm in south africa and giving me prices in Rand. Ooooh, and while i'm at it, canceling the screensaver without opening links to weather/majestic forest/some travel agency would be nice too.

-

I find the first frost of the winter to be quite a reliable battery tester /worked well for me this year //i'm told the repco style one that applies a load is the way to go

-

The flow meter will be calibrated for Argon, but as CO2 is roughly the same density, it will make no difference

-

Would it be right that the forgings are all pretty similar (if not identical origin) and the cost is to the amount of machining and finishing? Having been involved in making conrods, they are pretty high up on the simple but complex scale, cheap ones may work if they have a good process to shovel them out? The difficulty we had was linking every step, locating the stock, boring the gudgeon, pressing in the gudgeon pin bush, then re indexing to bore both ends parallel, without taper and then repeating that many times over. Even with some spendy gear we still measured up batches to sort into matching sets. In saying that, if I could get the raw forgings, i'd be giving it a hoon cos each step is pretty simple.

-

Random slightly cool stuff you built but not worth its own thread, thread

NickJ replied to h4nd's topic in Other Projects

Run diesel in mine, not really potent enough but anything decent melts the pump -

Hooooooly thread dredge! What advertising service is behind these ad bots, guessing its a webhost platform? Kinda amusing looking back that since then I have ended up in the CNC world and can now answer that question over a few different processes. @oldrx what are you after? I'm shifting my bigboy router back up at home as soon as this weather clears, within reason happy to fire parts through for OSers Also have contacts with a few small one man CNC outfits who can do anything else for a reasonable rate and be helpful at the same time

-

Just link to the relevant aliexpress page would be an easy improvement

-

Yep, Bunnings has bonus points with me for open 7 days, helpful as it correlates well to the most likely day to run out, Sunday.

-

Well, lets rip into it eh? Engine out Only took a few hours which was quite enjoyable, where's the catch I wonder, ahh, there it is Seems someone didn't want the cross member bolts coming undone, bit of an awkward wrestle eventually giving way to the 3' breaker bar Steering arm thought it would try a similar game, I had a lazy trick for that on a block of wood And then reality drops by, nothing bad, just that old demon scope creep. Plan was to pull out the cross member to sort a flogged out hole, realisation now is that if I want the engine bay painted in the future, it kinda should be done now. This sets the scene for replacing more bits, fixing more oil leaks and generally going a bit overboard. Which leaves me today with a very lightweight Lada Some would say not far off a bare shell

- 78 replies

-

- 22

-