-

Posts

3400 -

Joined

-

Last visited

-

Days Won

1

Everything posted by NickJ

-

As far as OS goes, this thread is pretty PC

-

Throttle spindles wear out on those carbs, mega air leak down the shaft and you can never get a steady idle. Checking play is hard to do with the return springs in place, but if you hold it at half/full throttle and can give it a wiggle, chances are its time for a spendy rebuild

-

Yep, i'll pop along for a hello and a burger

-

tax some from ya neighbours for us please

-

Yes/No, I actually thought it would be a good way to size the system for cheap and then buy legit ones. The tapered threads on the Ali ones were that terrible, I doubt they would make a seal of any confidence

-

Workmate just brought a stack of chinesium AN fittings for an efi conversion, macaroni elbows would have been a superior material choice.....

-

Random slightly cool stuff you built but not worth its own thread, thread

NickJ replied to h4nd's topic in Other Projects

That heat pump cover is awesome! -

My father actually ordered them from Australia to cover all his collection, i'll try to remember to ask next time I chat. A quick google brings up a few on ebay so there should still be a few about.

-

That was round 1, I changed to this design to see if that gave more "pressure" in the mould Also the next badge I really want to copy is much larger and to my current observations won't quite work this way.

-

Yeah, 2 vents at the top. Can see the intended pour and vent, I thought gas would get trapped in the small point. Turned out that got blocked from gas and general bubbling away, couldn't fill quick no matter how hot I got the mould. So I opened the vent up and used it as the fill point and the original fill as the vent, that worked perfect, couldn't pour fast enough and little to no bubbling. Apologies if my terms are incorrect, I'm pretty much just working this out as I go! Small pin holes is a good idea and makes sense now I have had a play, this shape seems happy, but it is a concern on the next badge in line.

-

Had another go this afternoon... After many attempts and mould redesign, this was the best. With the part standing vertically in the mould on the left edge, the first half is perfect and the top turns to crud. Worked it out to be the metal cooling fast during pouring as I only have 80g in the pot, more metal, more thermal mass.

-

Gave it a hoon today, made a mould with plaster of paris, heated it to 150C then poured in lead free solder. Only issue is the detail didn't come out. Mould not warm enough/too warm? the left overs that I poured into a piece of aluminium had full detail so thinking to try again cold.

-

Yeah we're mainly large CNC machines, yes they could do it, but its not the kind of work we do daily, even then a top level motorsport machinist would be cheaper! I have a bore gauge at home that could measure into the pockets if you want to look that close?

-

That really sucks to find that this far in! Get that block in for a tickle up ASAP, hard to tell from the pics but often the depth looks worse than it is.

-

I can still hear that Corolla....

-

I know nothing about that regulator, but thinking out loud... For a fluid to make noise you need cavitation/turbulence, that suggests high flow, I assume the engine isn't sucking excessive amounts? what kind of flow goes back to the tank? Can you try throttling the flow from the pump to slow the feed to the reg/ is it sized too big? Also the feed does a 90deg right as it enters the regulator, can you remove that and see if it helps?

-

Do you have a link to the shop that sells it? I feel this is a good wet weekend activity

-

I put a piece of black tape down the middle of mine at wof time, old mate didn't see the joke

-

I had an error between chassis number in the system and actual chassis number, something like a 1 and 7 mix up, man at the testing station was being a dick about it, but his boss took the papers, walked into the office and came back job done. I have no idea what the actual process is other than it is possible.

-

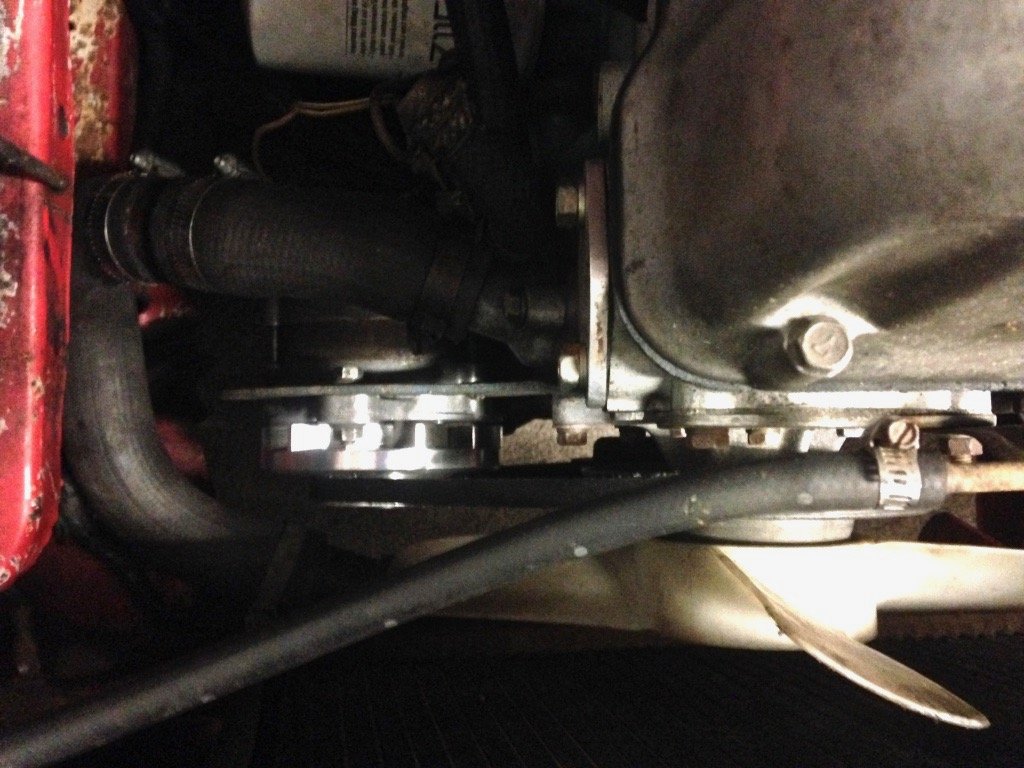

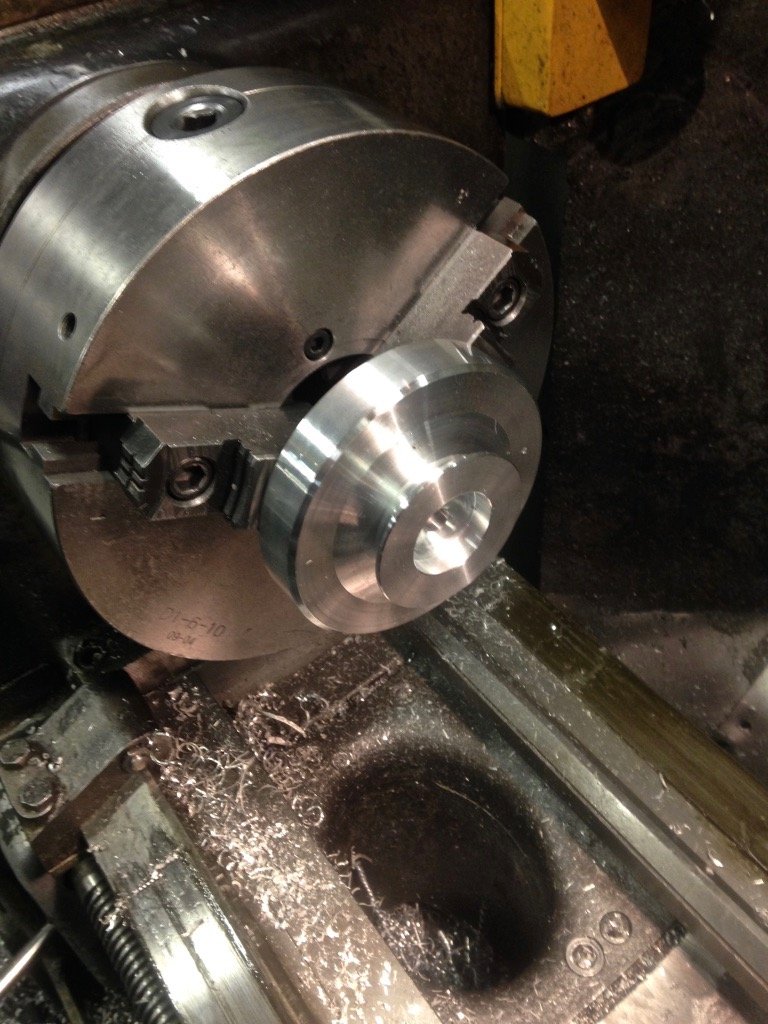

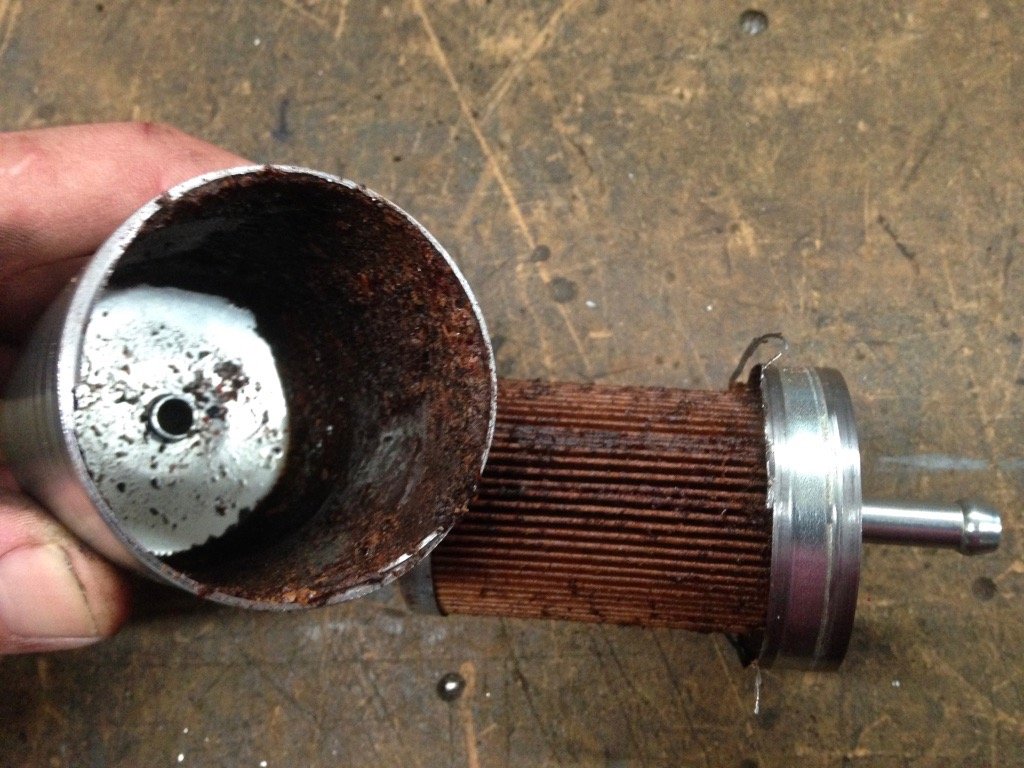

Quick fixer upper for one last hoon on Queens birthday.... Someone left coffee grinds in the fuel filter..... Yep, that sucks, tank is gunna have to come out, will be put on the winter list. Considering the filter is ~2 years old so I am going to just replaced it and let the rust be tomorrow Nick's problem. The alternator issue turned out to be an OK repair, considering I went about it the hardest way possible! The pulley is meant to have 2 flats that engage on the shaft, my guess is that years ago the nut got loose, was also stripped at some stage in its life to finally work loose until it spun and made a right mess of the lot. My fix? In some odd moment of cheap and quick I decided that fabricating a new pulley was the correct approach. (I really should have just fizzed the pulley onto the spacer and been done with it) Step 1) Wait for the workshop staff to go home and leave some machines unguarded Step 2) Spin bit of 6061 real fast like Step 3) Dig around behind the CNC mills and uncover a largely neglected indexing head and spin many dials real slow and orderly Step 4) Realise the M12 thread is actually poked and have to change the design, interference fit for the pulley and cut a M10 thread with stuff all material free. Step 5) Bake till crispy and seal in the luck thus far. Step 6) Plug it back together Step 7) Dump it back in the hole where no one will ever see it again. Step 8 turn in for the night, waking the household this late with Datsun noise will not be in my longterm interests, will be a long day waiting to test drive! Very stupid/illogical that I put in all this effort, half as much would have grafted a modern alternator into position with much less future hassle.

- 53 replies

-

- 27

-

-

As above, awesome effort to just give asking a go! There was a red scorpion with a fiat twin cam that popped up on facebook about a year ago, not sure where it went though

-

Discuss here about Yoeddynz's little Imp project...

NickJ replied to yoeddynz's topic in Project Discussion

I'm with Tortron, shrinkfit bronze sleeve thats then machined to size I look forward to your report that makes it look way more fun whilst neglecting the reality of hours spent dialing it in square -

Discuss here about Yoeddynz's little Imp project...

NickJ replied to yoeddynz's topic in Project Discussion

Forgive me for being too lazy to do the maths, but the contact area between the pipes is small compared to the surface exposed to the air/frame, i'd safely wager that any heat leak will be minimal compared to the cooling from such long runs. Imp looks pocket sized in some of the pictures, like it could be easily stored under a bench, the perfect car really! I wish you many pleasant adventures to come. Did they ever put SU carbs on the Datsun A series? -

Its now at the panelbeaters getting the worst of the rot dealt with, not sure what their exact timeline is but it should be getting close. That pic is post blasting and looking at the others he sent me, its actually in pretty good shape for a Datsun that hasn't moved for 30 years

-

Awesome, good man indeed, he doesn't need much to start a good yarn about Datsuns eh! I guess he's told you all about this one: Be sure to pester him at every opportunity as I do, need to be sure it gets completed in a timely fashion.