-

Posts

1,172 -

Joined

-

Last visited

-

Days Won

1

Content Type

Forums

Downloads

Events

Gallery

Everything posted by Sunbeam

-

Good news/bad news. Bad news first. I was driving to the local for my WOF this morning and as I downshifted to second, there was a popping sound, followed by the clutch pedal not returning. I managed to get to the garage and we popped it on the hoist to see what was going on. It was clear the cable had gone slack and further investigation revealed this had allowed the clutch fork to hop off the pivot ball inside the bell housing. About now I am very glad this bell housing has a release fork opening in both sides, because we were able to re-seat it. After a bit of faff and head scratching we realised the steel collar that stops the cable at the firewall pass through has let go. Less than 2000km on it since new! By tightening the adjuster as far as it would go, we had just enough clutch to drive it and PASS THE WOF (that’s the good news) I’ll have a fossick and see if I kept the original cable. After market sucks, people. Merry Christmas

-

Discuss here about Yoeddynz's little Imp project...

Sunbeam replied to yoeddynz's topic in Project Discussion

Hope the tyres work out well for you. Glad you didn’t get RP28’s as I can say with great confidence they are shiiiiiit. -

Complicated by the fact there are short and long nose versions of the 3.5 as well iirc. Often dizzy/waterpump style ie front cover version has greater influence on installed length.

-

Well done. It’s a good feeling getting an old car back on the road. Mine was only off the road for 17 years but when it clean sheeted its first wof I nearly passed out. I’m now finding lots of little things I want to fix…

-

Ga3_zo and kp60nick's honda logo of head turning fun.

Sunbeam replied to kp60nick's topic in Other Projects

Are these injected or carb? Looking at one for the daughter…. -

I haven’t driven this thing in months! I mainly haven’t had the time to commit to removing the dash to address the leaking heater core, so I’m afraid it’s bodge o’ clock Sucessfully hooned.

- 143 replies

-

- 13

-

-

Makes you realise how horrendous the later model bumpers are when you see it next to yours

-

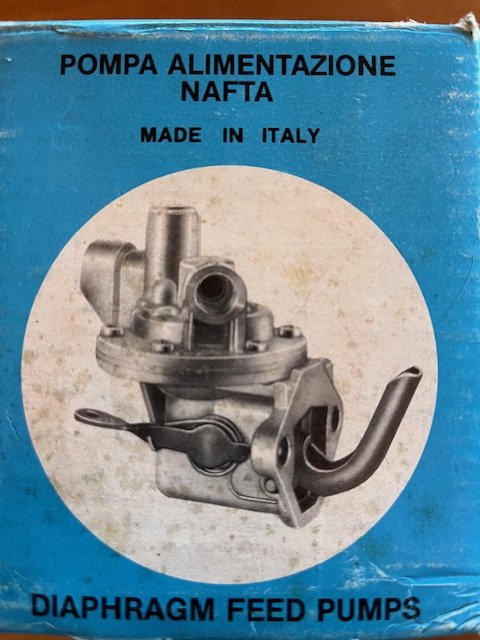

Parts from Slovenia! New(!) tail light lenses, caliper kit, fuel pump, brake master, water pump and front oil filter cover. Also got a heater tap and a coolant cap for the 125. Parts just sound better in Italian: And I loved the yellowed plastic the lenses were wrapped in, photo doesn’t do it justice. No actual progress, sorry. We’re in the process of building 2 sheds and a granny flat so car stuff is taking a holiday.

- 4 replies

-

- 14

-

-

Not done anything lately except order parts. Nice to get a proper steel expansion tank cap. Plastic one supplied by Midwest Bayliss lasted 1 seconds. Heater tap wasn’t cheap but worth hoovering up.

- 143 replies

-

- 10

-

-

Discuss here about Yoeddynz's little Imp project...

Sunbeam replied to yoeddynz's topic in Project Discussion

Sounds so good on the outside! Just drive with the window open all the time, that way you won’t need to faff around with tuning the exhaust. In fact, just remove the side window glass altogether and save weight at the same time, or you could put the glass in the frunk to improve the handling. -

If you matty b those epic maser rims I will find out where you live and burn all your shit down.

-

Yes. Effective and less exciting than air…

-

If the running in process wasn’t quite finished before, it is now! Fiat club track day! Thrashed mercilessly and made the brakes stink a lot! And realised my son is not a naturally gifted photographer… Nothing broke and many people told me my car sounds good. There were a couple of Ferraris, 3 Alfa 4C, and a Lotus Evora which was very nice. My car was one of the slowest but the only comparable OS cars out today were a V8 Fairlane, a MK2 Jaaaaag and briefly an Alfa spider. The Jag couldn’t catch me but I spent a fair bit of time being passed by modern turbo hatches. I’m very pleased with the way the Fiat handles for a fairly stock road car on chinesium tyres. Juuuust squeezed 100mph at the end of the pit straight which coincides with the red line on the tacho. If there’s a next time, I need better brake pads and I need to get the twin sideys on, she runs out of breath at 5k rpm. Son was fizzing as he got to go for a hoon in a Lancia Montecarlo race car (with added volumex).

- 143 replies

-

- 12

-

-

Leaky weld on muffler Right rear wheel bearing protesting loudly Out No in pics. Due to a lack of a press I dropped the axle and bearing kit off at Italian Job (nice fellas) who swapped it over for cheap. Wow, sooo much quiet! Much more pleasant to drive.

- 143 replies

-

- 10

-

-

Welcome to the dark side.

-

Gratuitous photo. To do list: Leaky weld on muffler Right rear wheel bearing protesting loudly Weeping heater core Left rear tyre touching the inner wheel tub on hard left turns One tappy tappet needs shimming Oil pressure switch weeping Build a good 5 speed from the two I have in stock and butcher modify the tunnel to fit it Rewire main beams with a relay fit electric radiator fan fit retractable front seatbelts, and fit rear seatbelts Otherwise, it starts and runs very well and I’m having fun.

- 143 replies

-

- 17

-

-

Would be interested to see if they are stocked. When I picked up my tubing from Autobend they told me those straps were unavailable

-

1000km post run in oil change time. Then I took it in for some surgery on the exhaust. I got sick of playing around with it so like a coward I farmed it out to a zorst wizard. There was much choppy chop and a quieter centre muffler was grafted in. Still sounds good but is now bearable to drive. Wizard made multiple angle adjustments to clear the diff and brake bias valve and torque arm. One problem to report: Whiff of antifreeze when the heater is on. GROOOAAAN!! Looks like dash out in my future.

- 143 replies

-

- 18

-

-

Snap! Have been dreaming of jamming one in the Fiat 1500..

-

Toyota wreckers are thieves especially van/prado/hilux ones. Buy every single wreck at top dollar, corner market, print money. Around here anyway. Good luck

-

What qualifies as cheap for one of these smurfs?

-

I keep seeing Max peed in his grods. Is that a euphemism for undies?