-

Posts

1,370 -

Joined

-

Last visited

Everything posted by shrike

-

Any plans to go back to DBW later on? Great progress, how far from firing it up again? just the fuel rail machining?

-

Surely someone could 3d print you a badge?

-

@Rhyscar sounds like an incentive to do a custom subframe or to clearance the existing one :p, a dimple die hole at the location of the headers might do it

- 417 replies

-

- 1

-

-

Any thoughts to go actual electric power-steering later on? ie Corolla, Prius, echo, 86

- 417 replies

-

D series single cam do like 40psi right :p

-

Any plans on an EK front conversion on the orthia?

-

Discuss here about Yoeddynz's little Imp project...

shrike replied to yoeddynz's topic in Project Discussion

Driving an untested semi tuned car in the rain is pretty ballsy to me :p keen to see how much more you progress and interest to see dyno results if you ever get round to it Thinking this and @RomanCarina need a photo shoot/ maybe a cheeky drag race What does the Imp weigh now it's all done? -

Surely someone on here has access to cad software that could analyse your file for stress etc if you sent it to them? Have you looked at how the 2GR adapter that MR2 guy uses is designed? I know that's cncd tho Edit ignore me, not the style I thought it was haha https://frankensteinmotorworks.squarespace.com/shop/p/2gr-velocity-stack-intake-manifold

-

@Roman the stationary cooling system test vids don't seem to be loading :p Bet your fizzing sounds nice and crisp love the intake noise Great progress looking forward to seeing more graphs

-

Daves new school holden shambles. (Is this project oldschool yet?)

shrike replied to Muncie's topic in Other Projects

And thats still on low boost yeah (4psi)? are you going to run a boost controller or just change springs in the wastegate?- 741 replies

-

- 1

-

-

Haven't done tig in ages (Highschool ish) and don't own a machine currently (My unimig does scratch start which I am hopeless at so don't even attempt) and my mig skills aren't amazing (look at my fake evo thread ha) But you are doing amazing and are definitely getting better with practice, like a lot of us here a grinder and paint make us the welders we aint. Even with stainless heat coating or wrapping hides alot and if it penetrates and doesn't leak thats a win in my book :p Nothing wrong with function over form Might be worth a brain storm with people that commented about your collector design in this thread before you send the next file off to be made, just to see if there is any other ideas to make your life easier Loving the progress, and im frothing with you for this thing to be doing stationary cooling tests Anglia4 did suggest cutting it to make welding easier as well Could always make it a interference press fit :p assuming they expand in the same rate when heated haha (im joking)

-

Daves new school holden shambles. (Is this project oldschool yet?)

shrike replied to Muncie's topic in Other Projects

So idle issue all solved? That's awesome news if so ♡ glad you got to the bottom of it Whats the weakest link atm? Estimated butt dyno power figures?- 741 replies

-

@kprwasn't sure what thread to throw this in or if youd be interested but Barry has the below for sale Can't remember if your running factory pistons or not

-

Keen to see how the rest of the exhaust comes out and great to see more progress No chance of 3d printing a complete manifold? or is it silly costs? Assuming you have done everything to prevent the cam failure from happening again now youve gone to the later model parts etc? I really need to learn CAD, some of this stuff is super cool

-

Time to make some wood gas?

-

Can always do steering relocation and conversions but adds complexity Steer by wire? A 4pot doesn't feel right in a crown otherwise I'd be talking K24 or if sticking to Toyota a 2ARFE ideally turboed. Barra has been mentioned but definitely an option as lots of support and parts etc around Tipping a boxer wouldn't fit between the rails? The EZ30 isn't a bad motor if that's your cup of tea

-

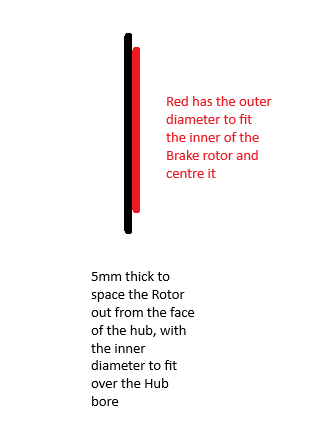

Got ya that makes more sense Yes if you had a ring with 60mm OD that was the thickness of the Brake Disc/Rotor and an ID of the Hub at that height that would center it fine If you have to make something you could make it so you could also center the wheels on them as well so it would be 56.1mm od for wheels to 60mm od for Rotor bore and Inner ID of 56.1mm? But if your happy with the wheels being studcentric no reason to complicate it

-

The problem with doing it from the front is That it could cause issues locating the wheels onto the hub centre? Any reason why it's stepped? If your spacing it out 5mm anyway you could make up on a lathe a tapered sleeve that makes the hub 60mm where the rotor bolts on, ideally you'd start at say 65mm at the bottom on the hub face with the ID of 60mm and then the 5mm up you'd make the OD 60mm and the ID tapered to suit the hub Not sure if I'm explaining that well Would make the hub 60mm to the height you need and then still allow the correct hub bore to suit your wheels @yoeddynzdo you understand what I'm trying to say :p To simplify ID at the bottom to suit the Hub OD of 60mm OD say 65mm or as wide as you can get it to the edge of the drive flange keep that OD for the 5mm spacing you need to space the brake disc then reduces to 60mm to fit the brake disc bore ID tapers as needed to suit the taper of the Hub centre I'd have it flush with the Disc hat face as long as you have enough height of the hub center to center your wheels on if not then you could step it down to the factory size after the disc for the height you need I'd start with a 70 or 75mm solid bar and machine it down from there Makes sense in my head lol

-

If you can find an off the shelf Hub centering ring that you use on wheels that are different bore to the hub you can put them behind the brake rotor Hope the below makes sense, ive done this on my AE111 for both front and rear rotors without issue, wouldn't be hard to turn up on the Lathe either if there isnt an off the shelf option Id probably make the black lower portion go out to the edge of the hub, could do these out of aluminum, or stainless Edit if it has a taper might may sense to make a tapered locating ring on the lathe

-

-

Daves new school holden shambles. (Is this project oldschool yet?)

shrike replied to Muncie's topic in Other Projects

Whats the details on that ECU I can have a look over here in Ozzieland if you like?- 741 replies

-

Yeah not much meat to work with, you could always mark out where 4x100 would locate and see if its doable Adding more material would be tricky and potentially obvious Whats the spline count inner and outer bearing diameter With the Ae111 I could swap to Rav4 as the bearing inner diameter was the same and the rear Im using bolt on bearings with the drive flange from a highlander (FWD was Camry from memory) Just wondering if there is another car that might work

-

Depends how you do it and if anyone would notice I guess My Ae111 5x114.3 conversation uses all factory toyota parts that bolt on so looks factory (well it would if it didn't have massive brakes etc) What do the factory drive flanges/ wheel flanges look like?

-

Ok so if you went 4x100 few options that would work in that range depends what style you like