-

Posts

4,794 -

Joined

-

Last visited

-

Days Won

1

Everything posted by mjrstar

-

Similar to @shrike suggestion my old evo had an idle voltage supply for the fuel pump presumably to reduce noise, and then a second relay when the engine was on a bit of boost. I fed it the full beans all the time by jumpering the relay that switched over to the full boost mode. Much easier to deal with when reflashing the ecu. Perhaps nissan has something similar? edit: As you were fine sir, must have been posting at the same time. Double edit: ecu is seeing less air when on boost than actually exists. So if its on a map sensor then start there.

-

Am I dreaming or do doritos have the water pump run either clockwise or anticlockwise depending on which model. I'm sure the pulley I machined for rx7 rally car crashing guy ran off the back of the belt, and he asked me to knurl it for extra grip.

-

You might need to remove the dpf for a manual cleaning if it's been persisting for a while.

-

That doesn't look miles away from a stock ITR header, what brand? As eventually I'll wear the bottom out on my stock headers. The bolts for the heat shields are about 1/2 to 2/3 gone now.

-

The ~200kw at 4000rpm range is the same as my old evo. It had a nice punchy feel to it.

-

The other thing to consider is the minimum clean cut thickness you desire. Excel arc on sale, bit more than the aliexpress price https://www.supercheapauto.co.nz/p/xcel-arc-xcel-arc-viper-cut-30-plasma-cutter/678424.html?utm_content=paidsearch-pmax&gclsrc=aw.ds&gad_source=1&gad_campaignid=19826383096&gclid=CjwKCAjw3f_BBhAPEiwAaA3K5E7c-segDyqzPS_Lw2krWf1mO29UcH_5Pu13HglI5kgvXBhn1y1wIhoCNbMQAvD_BwE

-

You'll need to decide if you want a cheap one with no built in air compressor or an all in one with built in air. Which will be a bit less admin /more portable. Most brands will offer both. We have an excel arc one at work, seems to do the trick. Local trade zone was good for service on an excel arc tig that got an unwanted drink and needed a new circuit board. Seemed cheap enough to repair and pretty quick turnaround.

-

In my starlet, i originally put it together with a 4.3, it was quite grip Limited with the way it delivered torque through the midrange. When I swapped to a 3.9 it was a much better combination, still a little bit wild but manageable, and better to drive overall with not not wanting to break traction at 1/2 throttle at 4000rpm. The diff ratio is just a speed reduction/torque multiplier at the end of the day. The question is do you want to target a specific cruise rpm. ( I'm sure the 20b would be fine mechanically around the 4000rpm mark) and fuel consumption will be garbage whatever the diff ratio. Because rotary.

-

Bring back @Post Merge , soz for the DP.

-

With a 20bpp are you expecting the car to be hindered by grip or torque? From a performance perspective if limited by grip then =taller diff, if limited by torque then go shorter. Not a lot of point in making more torque if it turns into smoke. I guess the other option might be a 6 speed with a long 6th gear used only for in the cruise, and ignored on the track?

-

Where do I buy a reverse rotation 4age, and a niteparts adapter to suit b series gearbox.

-

Where is the tldr, that guy went on a journey, and I did not follow. I suspect he spent a metric or maybe imperial fuckton of money on the engine to make a car that became pretty traction limited?

-

Truenotch's BEAMS AE86 racecar discussion

mjrstar replied to Truenotch's topic in Project Discussion

Dry sump the diff, the vacuum will mean no more leaks. -

I'd suggest at that rpm on a b20 it's likely running a set of aftermarket sleeves, which are reasonably priced but not cheap to machine and install. Or maybe he's happy to send it and wait for tye zoom zoom boom. A dude round these ways make good power from a b20 with darton sleeves, 48mm Jenvy throttle bodies and a set of eliminator cams. Put into a lightweight ef8 crx with a good gearbox.

-

I've had some success with a bit of belt wrapped onto the pulley, then get a pair of chain grips onto it. Depends just how seized I guess though.

-

Can you scan it to check dpf pressures or % blocked on the dpf? Even egt's might give an idea. There might be a calculation that if it fails a regen due to dpf blockage not reducing it decides that extra fuel has ended up in the oil. Take it to mexico. A pull a day keeps the dpf light away. In my diesel the parameters for passive regen are over 1/2 tank of fuel, up to operating temp and >2000rpm. It probably needs 15 minutes or more at a guess.

-

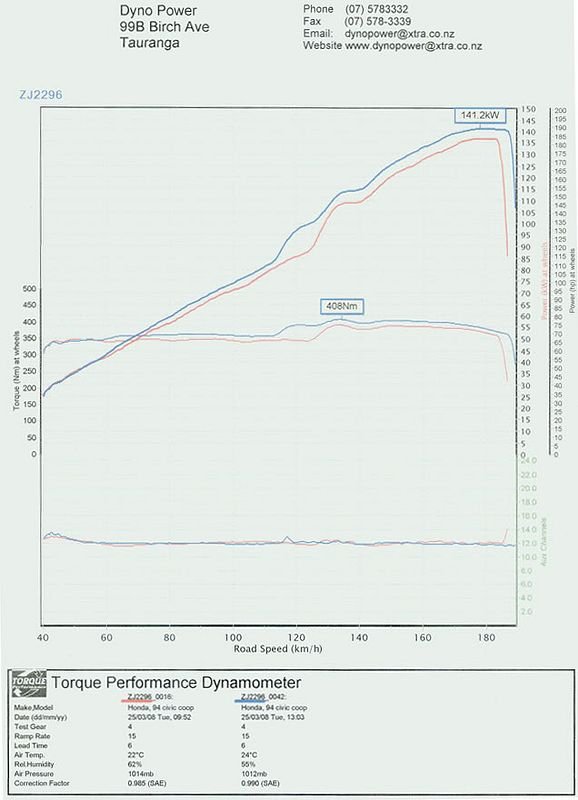

I found the dyno plot, the chip I had burned for my civic is the same one as was used on his own internally stock b18cr, although his had hytech headers, and a 2 1/2 exhaust. Whereas of course mine runs os approved 3 inch, with stock itr headers. It has a little wiggle on his dyno sheet, I don't notice it in real life.

-

it's pretty much stock, so it'll be whatever power honda made it have when it was new minus whatever it lost in the last nearly 30 years.

-

Mine is stock itr 4-1 headers, 2 1/2 from the doughnut flange then up to 3 from where the cat would have been to single 3 inch muffler. With a helmet on its noise is bearable, but without head gear not so much. Performance wise I have no idea if it's any good.

-

I recall 21 or 22 year old me going 240kph plus at pukekohe in my kp, 3 point belts, no cage, no worries. Wtf was I thinking. I guess the hilux brakes would have got a bit if a workout. And of course the occasional slide at the last turn at 180kph and dipping a wheel onto the grass. No thanks, not these days.

-

-

I was just looking at the blue and red squiggly lines and making an assumption about the cams.

-

I'm not familiar with the 176-b cam, but it looks like the off vtec lobes are basically stock? After having driven a b16a with Toda B's they would be my pick if I was chasing mid range and top end. Sure they have a slightly choppy idle but nothing too drastic.

-

Is it still stock 10:1 compression @Maru-So?

-

Could be, whatever it was it worked fast, wasn't there the night before and had appeared by the morning. Plus the car was in tow back from an event in taranaki for a portion of that time.