-

Posts

22,324 -

Joined

-

Last visited

-

Days Won

10

Content Type

Forums

Downloads

Events

Gallery

Everything posted by xsspeed

-

Chur, when you say strut brace are you meaning like a tower bar or something else? Another question sorry, from a starting point perspective, is it better to start with a (relatively) virgin subframe or would something thats had strengthening plates welded in be ok/of any value (have found a subframe that has these welded in already https://au.gktech.com/products/v2-s13-180sx-r32-gts-t-subframe-weld-in-reinforcement-plates) Also some reasonable info on S chassis subframes here - stamped, welded mild steel construction is noted - https://blog.gktech.com/blog/s-chassis-rear-subframe-comparison/)

-

I found a video that better explains the S13 subframe process

-

chur, feel free to spam my project thread (lol) thread rather than block up here @RXFORD i had only half though of full fab as then potentially getting into custom spec everything, where the beauty so to speak of the s13 subframe is all the relatively inexpensive/easy to source aftermarket support. That said i guess if could still use the pickup points for control arms/hub etc then that would still be an option, just a bare subframe with less ropey mounting points - will ponder cheers The other option is the just try and work with the trailing arm setup which is still kind of tempting from a cost point of view. Can do some eccentric bushes/bolts etc to get some level of adjustment when going lower Stock is like this: There is a kit that does this (cut and shut control arm and attach new mount points) which looks a bit sus maybe? Whats the legality of something along these lines? Theres a US fabricator making these subframes which stay as trailing arm (but lose the spring perch). I've talked to clint about these and would need a design review in nz, plus apepars its all mig'd and in NZ expectation would be tig'd Could possibly pinch some ideas from both and build a NZ spec trailing arm that allows some adjustability that still attaches to the Z31 subframe (and maybe keep divorced spring/damper setup)

-

The front mounts are a bit more of a trick, the s13 subframe is shorter, that Z31 so the Z31 mount points are further forward than the S13 subframe can reach Can one, extend the subframe like so (with non shit welds?) Standard subframe Front mounts fall short of Z31 pin location Cut front mounts/extended Boxed up Is there anyway to do this extension legitimately, any suggestions that might be better than this method? Edit: a variation I have just realised this build used https://www.speedhunters.com/2021/05/project-z31-432-getting-technical/ suggests you can somehow chopping off the mounting points from the z31 subframe and attached them to the s13 subframe to get to the z31 mount position, cant see a good pic of the front mounts in link, I've asked the dude if he can share - can just see the s13 ends are cut and shut

-

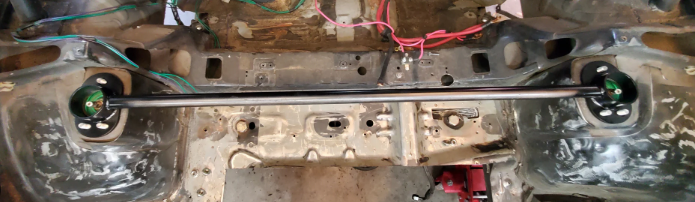

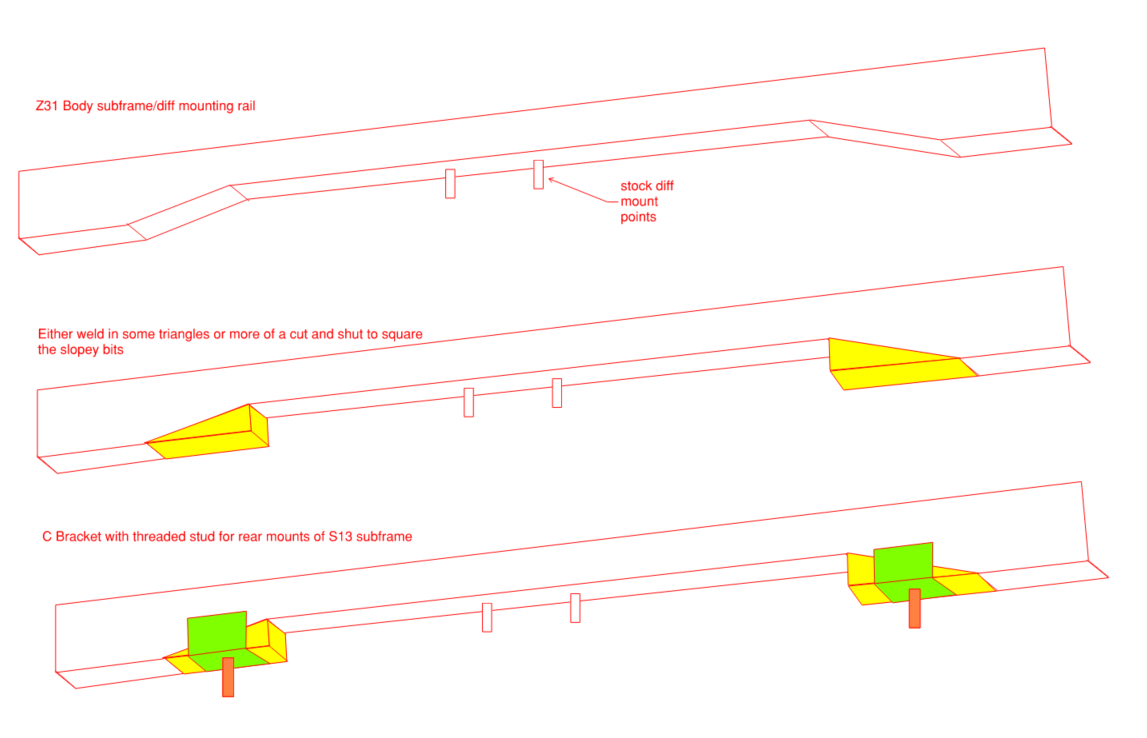

Clint I have been fluffing around a lot on the Z31, trying to establish a direction and get going. I wanted to float this to see if there were red flags before taking any further The Z31 rear trailing arm setup is a bit shit, S13s/14s/15s etc have multilink rear which is pretty sweet plus loads of aftermarket support Some jokers over the years have figured out ways to get S13 subframes mounted, problem is most are in the states and seem a bit questionable in terms of quality, however the principle seems sound The position the rear mounts of the S13 subframe want to be (apparently) align, front to back at least, with a factory mounting rail on the Z31. However the left and right S13 mounting points are more outboard. To make a mount the shape of the rail needs to be changed and a stud located for the mount. Simple diagram below: Pic (pre welding and pre installing of the stud) of the tidiest example I could find And post welded/stud installed So first question is for achieving these rear mount locations, is this welding in a wedge/cut and shut an accepable thing to do? Second question is, as you can see here, you would then use coil over spring suspension for an S13, rather than the divorced spring and damper from Z31, using the existing damper tower. I think we talked about this once where one may need to strengthen the tower? Next post for third question which might be the diciest part

-

1.45mm is a big gnats cock just sayin

-

+1 love the work man

- 418 replies

-

- 1

-

-

what calibrated gluteus acceleration sensors arent science?

-

@cletus does that bottom right one look like your gramps? it made me think of that old pic you shared edit: woops apologies for spam

-

chur, yeah realised i sound dumb posting this after a dig around and reminding myself but id forgotten everything

-

ive forgotten everything speeno told me about painting, and not in the right vein for this thread but im talking to a joker about a doors shut spray for my daily, he is proposing base coat followed by 2k clear. base is not 2k, is that all pretty normal?

-

-

there seem to be a number of billion HP rb2#/rb3# in existance already, source HRB's instagram lol

-

I mean specifically the one you've sourced sorry

-

What was the 2mz in, a windom or somethi g? Not exactly many around?

-

Lols well played, good jerb

-

C11 tiida e11 note F11 cherry G11 sylphy

-

Is it a d21?

-

Sounds like too much of a project and I know Alex doesn't want to go down a path that leads to a kswap

-

Is there a sweepstakes on colour, I'm hoping for a dark red, kind of thinking it could be a dark bronze/brown too tho

-

With that effort wouldn't you just convert to manual? Gearboxes aplenty for HR engines

-

Now like k11s every time I open Instagram I expect my eyes will also be exposed to z11s And yet weirdly next to zero e12 nismo notes

-

What spec is yours? I have the 1.6 manual one

-

Tomble's adorable go cart / distraction / Alto Works

xsspeed replied to tomble's topic in Other Projects

read whole thread over last few days, what a journey, lush doing this with misso and mates did you end up doing anything with this, i recently encountered same sort of issue with imported car and would rather not drill the plate (my plates are slim size not the jap size so i dont have any empty space to drill through - would be through a letter/number - the mounting position seems the same relative to top edge as your jap plates) seems like a good several mm by which it ought to sit higher