-

Posts

22,319 -

Joined

-

Last visited

-

Days Won

10

Content Type

Forums

Downloads

Events

Gallery

Everything posted by xsspeed

-

A pack of arseholes

-

no painted floors or violated spiders

-

Buick v8 bronco

-

nah I sold it cos it was getting on/fucked, i didnt expect my diddle to shrink though /spam

-

im just tryna get a longer deck

-

that was just an example lol i'd seen some of those towbars and figured they were pretty light duty and just looped off the tray

-

whats the go with the towbars on long trays like this, presumably cant be rated for much. (im guessing theyre just a hoop off the tray)

-

sounds like a volunteer

-

Thanks both, yeah @440bbm I figured all those thing so like you say need to weigh up if worth it

-

@cletus What are the legalities/hoops involved in changing wellside to flat deck or just send it? Are there dimension restrictions for overhang width/tail? Reason for asking is I'm in the hunt for dbl cab ute which for the most part are wellsides so will put a tray on. Also wanting to consider a longer tray deck so am looking into if a cab plus tray can work as theyre a bit longer (she said). Would there be more to it than the obvious mounting locations and mudguard positions

-

i thought it was the certifiers who get kick backs from big tyre

-

would you have looked twice at it, then checked the sheet?

-

That's a 225/50 on 16x9, where max is supposed to be 8

-

makes sense if you think the sidewall construction of a lower profile is probably tougher than a balloon

-

I'll grab a Pic tonight, I put some that should be illegal on my 16x9s for test fit purposes only and I'd be keen to get your opinion @AllTorque based on that comment lol, they don't look suuuuuper stretched to me at all

-

Yep it is, will see how long I stick with it before it gets abandoned I hadn't looked at 30s @Roman, I think I might have ruled out assuming the crank doesn't fit or something but a quick check says it does, down another rabbit hole I go I guess Edit: Quick check was google AI which said the mains are the same but chatgpt says 62mm mains for rb30 which seems to correlate to other sources so think google AI picked up something awry So will scratch that off the theoretical list Edit 2: if it were possible dave the RR would be 2.13

-

We'll make use of @Romans exhaust tuning services https://www.instagram.com/reel/DJGL_sJT1Rc/?igsh=MXV2ZGI2NzQ0M21rbw==

-

Rb24 probably gunna sound like a 4gr or something shit

-

Yeah turbo still, sorry didnt spell that out when i was talking about rpms and the n/a z31, though I think this would be the approach id have taken if i was in that n/a z31 dudes shoes I haven't really dug into the rb20de neo head, as I pivoted pretty quickly - i couldn't find much on them so i was planning to CC the head at least as dont know what the combustion chamber volume is/i still can. I did compare intake ports a bit, will need to dig that out as they are similar to r33 spec rb25, but a touch smaller. Valves are a little different to rb20det too I dumped some compressor maps in a thread a month or so back, i need to dig them out, there was a BW turbo map that looked not bad, i need to do some more work on what turbine housing A/R to choose though, and it will be a bit of a balance between response and able to flow at top end of rpm range I think it will still be a bit suck it and see as even with all the selection advice its all going to come down to the combination of things working well together. At the end of the day i know just dropping an rb25det in would be easier and more power but this is a fun distraction from the real world for now

-

Xsspeed's 1988 Z31 Nissan Fairlady Z 200ZR 2+0

xsspeed replied to xsspeed's topic in Projects and Build Ups

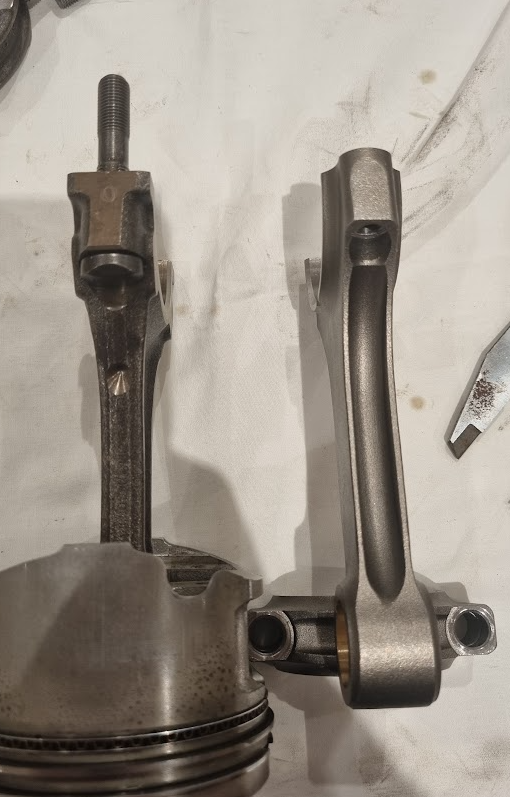

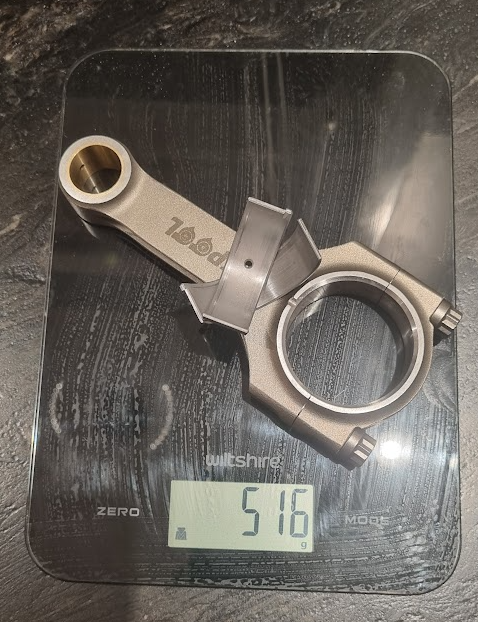

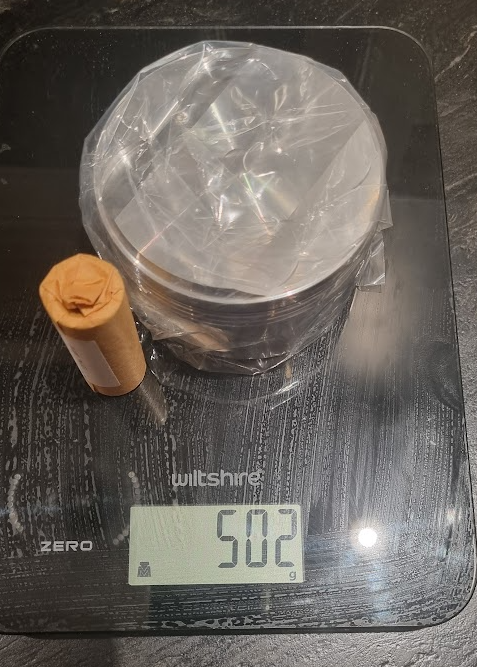

And a bit of a weight comparison Factory RB20DET 1060g And Spool RB20DET rod plus HKS piston (less rings) + = 1018g Im guessing once the plastic and paper is gone and rings added it might be a handle of grams more net... plus the 4mm extra length in the rod to come So all in all looking like pretty much the same sub-assembly mass for the 20det factory rod and piston (121.7mm rod, 78mm dia piston) and the "RB24" combo (125.5mm rod and 86.5mm dia piston) which while i was hoping forged equals lighter, it is bigger so its good to know I havent significantly added mass Next steps are dummy up the rb20det crank in the rb25det block and cradle to verify the mains are the same size as all the literature says, and I should probably fit up one rod/piston to confirm the relative height to deck before pulling the trigger on the rods tell me im silly etc- 19 replies

-

- 23

-

-

-

Xsspeed's 1988 Z31 Nissan Fairlady Z 200ZR 2+0

xsspeed replied to xsspeed's topic in Projects and Build Ups

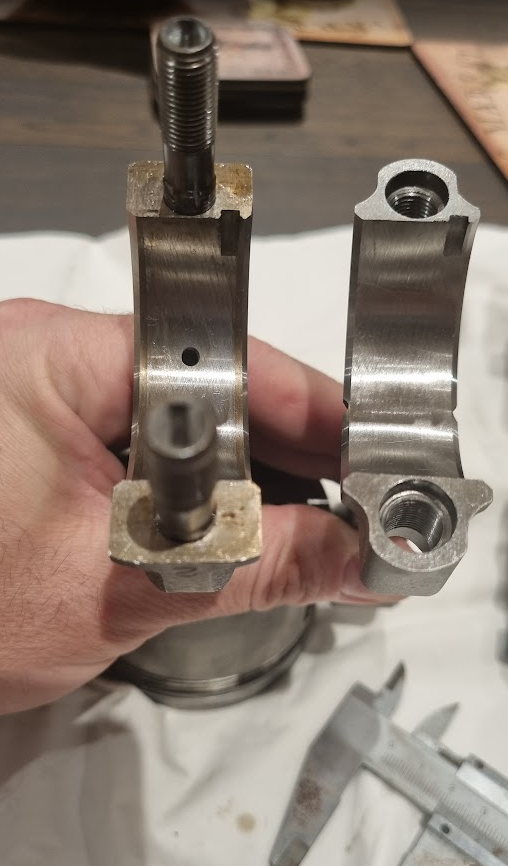

OK so time flies I didn't finish the radiator repositioning as I started to go down engine rabbit holes and figured its probably going to end up somewhere non-stock anyway - that in itself is a rabbit hole I have been acquiring a lot of parts and spares so over the last however many years which will help with restoring and giving some period touches However, the topic du jour is the engine. So I started looking at what people do with RBs and Z31s, plenty just run the redtop 20 or replace with a 'more modern' r32 unit. Others go down the rb25 route or rb26. Now while I had been pondering concoctions of RBs i discovered that, it was at some point a thing to stroke your 20det with an rb26 crank and rods, and bore the block and use 4agze or tomei pistons to achieve an RB22/23/24 depending on your recipe. I liked the idea of this so started getting some rb26 bits. Then i learned of the rb20de neo with better flow heads than the 20det and so i grabbed some of them, you need to do similar work to the heads to rb25/rb30 concoctions so it all seemed feasible. Theres a guy who is a contributor to speedhunters in the states who stroked an rb25 with rb28 gear and ran it N/A while shooting for 10000rpm, which is a sweet build but didnt get to the rpm he wanted. now after many late night instagram DM slipins with dave and boning up on stroking my...where am i going with this...oh stroke, rod ratios and mean piston speed become settled that sticking with the puny rb20 stroke of 69.7mm was conducive to high rpm* Now I like many have been inspired by the trials and tribulations of @Romandayf and his quest for lego engine parts and revs to the moon. So i did a bit of maths, and joined the dots a bit with @kprs long rods, to figure i could actually destroke a 25det, with 2mm longer rods. better yet i could use the hks pistons from a rb28 which has a compression height of 28mm rather than 30 to gain another 2mm of rod length (if i was going the custom rod route anyway)...this destroked rb25 ends up being about 2.4 litres, so another version of an RB24. And as it turns out there was a factory rb24 but it was a sohc(?) carby thing in malaysia(?) seems hard to track down details but looks like it used rb20det rods and maybe just taller pistons So research RB24s, and noone says its worth it, be it stroking an rb20 or destroking a rb25, so might as well go in balls deep right? I dont need big power and i really like revs so lets see where this takes us. (Downstream question will be can the rp71c gearbox keep up, i hope so given it should be power at higher rpm and so less introduction of torque but there will be some, and id also rather not have to drive around a fragile box as thats not fun either - thats future steebs problem Which (skipping over a bunch of other shit) brings me to now, I grabbed some HKS pistons for a bargain, and currently in the process of ordering rods One of the sticking points with ordering rods (for me at least) has been the notches for the bearing tangs, which kind of seem a bit innocuous but are obviously there for a reason. Because of the geomtery of the rods its hard to get good reference points with verniers and I didnt really want to guess. So I chatted up the guys at spool who do a rb20det rod and got some help. I bought a single rod from them and they also gave me some of their drawings which has been super helpful. One weird thing with the factory rods, and this is more true for the rb26 than rb20 is the notch kind of straddles the joint in the conrod big end. I really wanted to see if it mattered, but as you can see the spool rods notches dont straddle the joint, and these old stock bearings seem to fit up fine Another weird thing (to me) is the offset from front/rear for the notches is not the same, so the bearing shells themselves are misaligned by ~0.4mm - I don't know if there is a purpose for this or just doesnt matter Anyway - pics comparing stock rb20det rods/big ends to spool rods/big ends Those with a keen eye will notice the spool rods look a lot like a lot of other rods, see conrod tech thread, and i can't find a discernable difference visually yet which supports the theory that the same outfits in PRC are making these spec of rods Bit of a look at the spool rod: Bearings fitted You can see the offset i mention here Bit of comparison, factory on right Factory on the left here *in theory- 19 replies

-

- 10

-

-