-

Posts

24,247 -

Joined

-

Last visited

-

Days Won

3

Everything posted by Bling

-

Idiot proof methods to bring car window glass back to new? Lots of grime and some wind-blown dots from painting. Have used razorblade in our of the way places as a test and it comes up good. But could damage glass so wondering what others do? Does a clay bar take all that stuff off?

-

Yeah mix will be nicer to use, but honestly i've not been limited by pure CO2. You adapt to each gas. I've measured 0.5mm sheet and tack welded that with pure CO2, it had no use, I just wanted to see if it was possible. Old escort panel should be a breeze with it, with practice. I certainly wouldn't change gas and expect it to solve the problem here. Not that there is a problem as such, just need more practice and to know what to look for.

-

Will try this week. In the meantime, get a few bits of scrap panel and just try welding tacks on them. Literally just try weld in the middle of a bit of scrap. Then turn it over and see how obvious the weld is. Too cold and the surface will look like normal. Penetration which you want, will start to form a molten pool on the underside. The idea behind having a few bits of scrap is so you don't build up the heat too much, which will throw the results out. Maybe post up the settings you are using too. I always do a test weld before working on the actual job too. That photo I posted earlier I had some sheet, same sheet, on the bench and did some test tacks to make sure the settings were ok. Biggest hurdle with your patches were the gaps IMO. They are weldable, but only with practice as they are a bit harder to do. Easier to weld when the panels are butted together. With gaps, you have to get creative. Once you have one tack that bridges the gap, I tend to weld to the tacks which will then melt both panels together at the edges. Trying to weld into the gap by starting on one panel or the other will be blow through city.

-

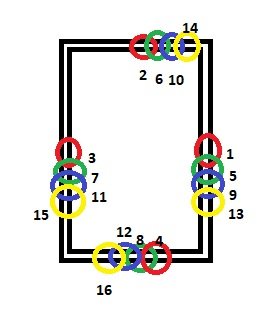

So, not a pro welder etc, just showing how i'd do it. On a small patch i'd potentially even have a little break between each set of 4 tacks, to avoid heat build up in the panel. Heat build up will change how it welds, too much heat and apart from the panel potentially warping, the chance of blowing through will increase. So maybe 1,2,3,4, break, 5,6,7,8, break. The smaller you can make the gap between the car and the panel the better too, less chance of blowing through, having the wire go through the gap or even melting the edge away from the panel. If you can have them a tight fit, that will make it easier to weld.

-

Flap discs for me, and it's only if it's going to be seen really. A lot of my repairs aren't seen so I leave them as they were when welded. Checked your project fred, yeah looking a bit cold. What I do for patches like that, is do a few decent tacks to hold it in place. Then I weld right next to the tack, aiming the torch at the gap right against the tack already there if that makes sense. What it means is the wire won't go through the gap accidently as it hits the tack that's already there. I'll try get the welder out this week and do some photos of what I mean as it might not make sense.

-

Post some photos up of practice welds done on bench, or even the patches you have done. Here is some I did in my boot, laying upside down. Welder settings are relatively high, for the material thickness, but I do short welds just long enough to fill the 5mm holes I had punch in the bottom sheet. Gave good penetration which showed on the topside with a bit of metal protruding top side too on the plugs. Example included in spoiler.

-

100mm or so squares of panel steel for practise. The panel will heat up, so have a few you can cycle through to get the most accurate results. Then i'd just set the welder and hit the panel. So a few "spot welds" and see what the result is. Post them if you like, i'm sure plenty on here with more experience than me. But you can tell a lot from a weld as to what you may need to fine tune. I have a BOC welder which has a few settings on it, so I can't give you the settings for yours. But I find it pretty forgiving. For example, I was welding some 4mm plate to a 10mm section the other day for an exhaust bracket. Then this last week I plug welded some just shy of 1mm body panels without even changing the welder settings. A lot comes down to how long you pull the trigger for, distance from work etc. This is with CO2, it's all i've ever used at home, no problems.

-

Will swap for cosplay photos. /didn't take any sorry

-

Cracker day for it, some sweet whips too. 10/10 for Wayne's balls.

-

VIRM should have pretty decent diagrams showing where it's required. I was looking the other day (but too lazy to google it right now) and it showed all sorts of angles and where they were required. Cletus may have actually posted it on a previous page, I have a vague memory of that so could be worth a look. look up virm mudguard, should have all the info

-

It's because no one uses CD's anymore* and people want laptops that weigh nothing. I haven't had a CD drive in my PC since forever. On the plus side, USB drives are cheap and you don't have to carry around CD drive components in your laptop for that one time you need it. *Certifiers are made to

-

Worst case you could make up a battery pack that plugs into the charging socket? edit: yeah very true on CGA, sounds like a decent case.

-

Do your best bog the rest. You can only do what you can do, anything is better than rust left in place. If you can enclose it inside something that stops moisture getting to it I'm sure you'll be sweet. Plenty of repairs don't get a full treatment due to no access.

-

Can you not get access? I used to just glove up and brush paint over the epoxy repairs usually. Often blindly then i'd just take a photo and see where I missed. Depends where the repair is too, can get that goop that covers everything in sills etc. Chuck up example situation.

-

Just reposting Bookface for those not on it. SUNDAY 11th Oldschool.co.nz Christmas Meet Ouruhia Domain from 11am we will have a BBQ. please byo drinks and meats. we will provide sauces and bread See you all there! If you haven't been before, rock along, we are pretty friendly.

-

Yeah should be able to pop some back out.

-

In my experience, the amount of fuel you go through covers enough tax. My auto one would use 15L/100km no matter how you drove. I took it to Nelson once from CHCH, had to fill up halfway...reliable as fuck though. As for the dented up car, unless it's a WOF fail, why even fix it, sounds like it may happen again so save the money / time.

-

Pretty hard to beat CD's price wise, i'd say they are more reliable too for long term storage. I grabbed one out to put photos on for this reason this week and each time I plugged the USB stick in, it wanted to be formatted lol. Gave photos on a SD card in the end as have no means to burn a CD easily. Check out Amazon.com.au for CD's Clint, half that price there (unless you buy them with cases) with free delivery if you spend over $xx

-

I'll look into that tonight, you'd think so, but i've never tried it. Not sure on Androids capability in that regard. /ling got a model number for cd writer?

-

Depending on the tablet you have, you may be able to get a slimline USB cd writer, if you haven't got that bit sorted yet.

-

Do you watch the Skid Factory? Their latest video was dealing with a turbo 1UZ, not sure if any of that can transfer across to your setup or not. That had pretty hefty cooling in it but it still got too hot. Just thought i'd mention it in case you don't watch them anyway. It might give you some ideas. I know the setup is pretty different, but perhaps something will cross over and help if cooling becomes a problem down the road. Cars looking gooood, gotta be happy to have it on the road.

-

Measured mine while doing other jobs today, ~15mm inside diameter on the pressed in seats. If I had known about them I could put a bit of planning in to it. But as it stands i'm happy with the new studs as it will mean I can run common nuts and I already have them, so there is that haha. Cheers for the heads up though, they sound like they would solve the problem with minimal work. Pretty keen for some better quality nuts though at some point. Might hit you up if you don't mind, as so much garbage on the market these days it's hard to find quality.

-

Yeah not something you see every day / ever really. The shape really grew on me when I found my first one, hadn't seen one on the road before, not that I was looking, but yeah not many around. Those with them tend to have multiple if the internet is to be believed. Didn't actually know those were a thing! I do want to get some new nuts at some point as my current ones, even though were new, are flaking a bit. Might look into those, or at least measure my wheels for fitment. Cheers

-

I thought someone made replacements? Think it was in that link but haven't checked. That seemed like the best value way to go. If you are doing up a car, especially an old one and reusing old shocks, they'll need replacing at some point even if it's not today. So do it once, do it right. If they are knackered, the car will never handle well. I had a shock blow out while on a long road trip. Couldn't work out why the car no longer wanted to stay on the road on corners, scarily so. A seal had gone I think and all of the oil had pissed out.

-

In the bin. Unless this is a looow budget build, you will not regret new shocks.