-

Posts

14,310 -

Joined

-

Last visited

-

Days Won

88

Content Type

Forums

Downloads

Events

Gallery

Everything posted by cletus

-

Finished Did the carb as well Goes better, is a lot more responsive and definitely has more beans in the midrange of rpm According to the tuning book methods of seeing if its tuned right, it could probably do with next size up in the jets , which came with the carb so I'll try that, I could also put a afr gauge up it's bum to check Slowly getting through the list of improvements, suspension is probably next on the list, as a little bit more ground clearance would be handy

- 528 replies

-

- 14

-

-

Ooooffff that's going to look nice

-

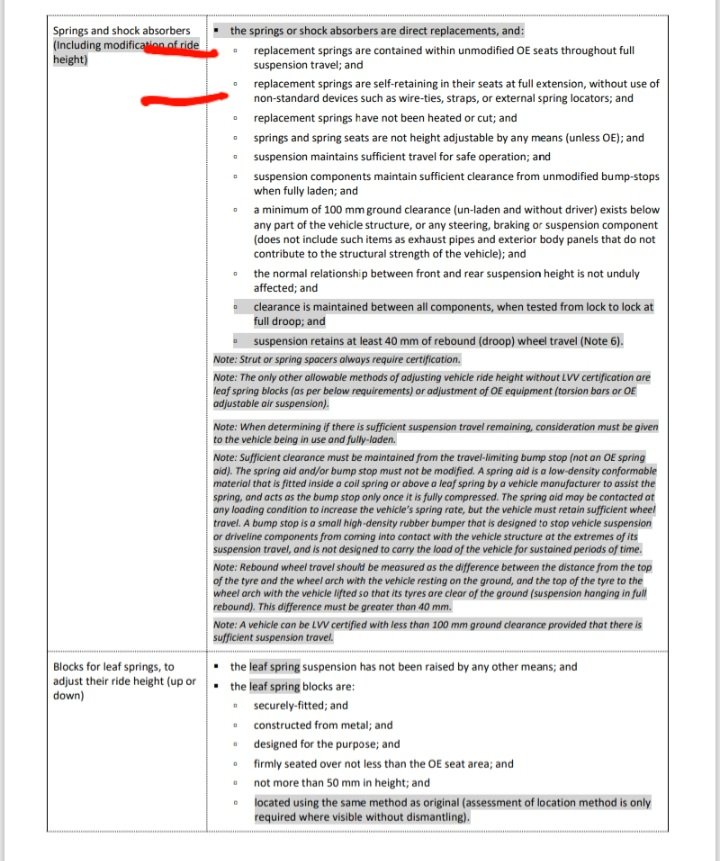

Rules, for not getting a cert = can't have a non original spring seat = can't have any means of spring location that isn't spring being correct length So those bilstein shocks technically require cert unless factory fitted to that specific vehicle regardless of if they have several circlip grooves or one. As for if you will have trouble with wofs? That will depend on the wof persons knowledge. There's probably tens of thousands of cars that should have a cert that dont, because the most common phone conversation I have is "it's been like that for xxx years and the wof guy says I need a cert now because the rules changed" (they didn't, someone just read the book or got reviewed by nzta)

-

Yes, they can be remade

-

Random slightly cool stuff you built but not worth its own thread, thread

cletus replied to h4nd's topic in Other Projects

Plz fit side pipe with a glow plug in it, my mitsi van had that accessory and it did awesome blue flames out the side -

Nah I didn't want to do more mods or have something that rides shitty down low , this cam set is as big as you can go with stock everything else This cam plus a carb upgrade and the pipe it has should be 85-90hp, which is probably good enough

-

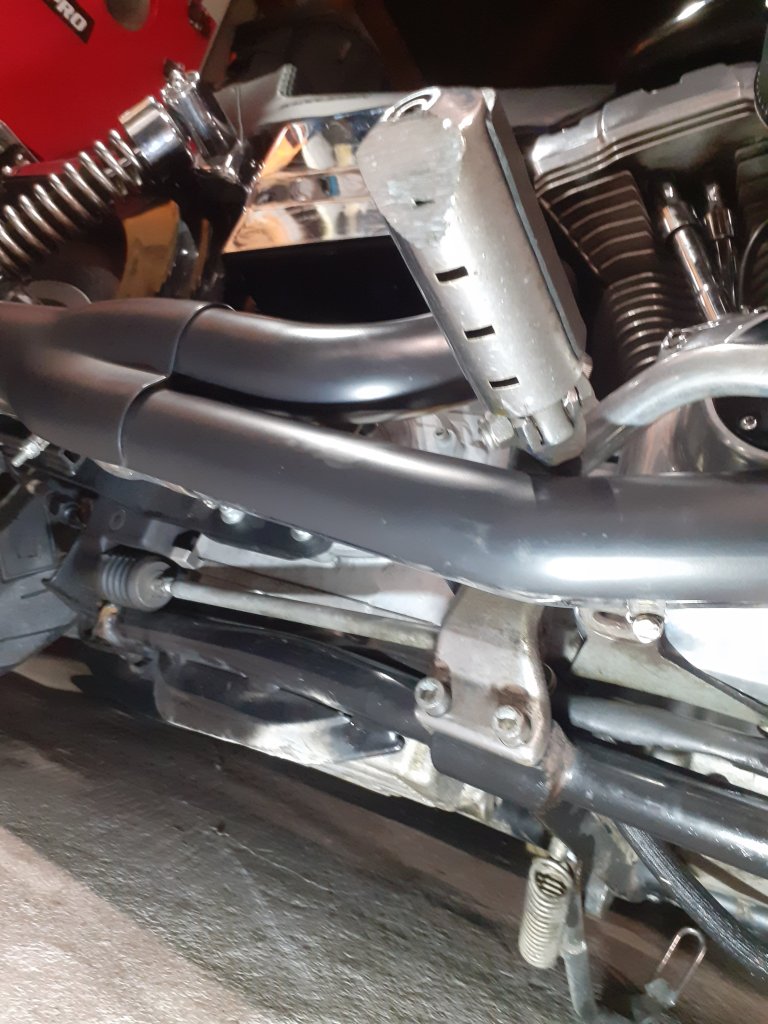

Time to do the tensioners, as if they break, bad, no fun time ! Since the cams have to come out it would be rude to not put better ones in , so purchased some cams that have skulls, eagles, hooded figures with scythes, etc New lifters, chains, gaskets, bla bla Most people that do this, put quick fit pushrods in, where you literally get bolt cutters and chomp the tubes and pushrods in half them put some adjustable ones in, this means you don't have to pull the tank, rocker covers etc off. Saves time but a set of those was another $500 or something and it seemed kind of wasteful so I just decided to do it the longer way. I can see why a shop would do it though as labour cost would be the same as buying the adj pushrods Anyway took all evening to get to here. I think I'll do a carb upgrade at the same time while I'm in here, weber specialties has a mikuni clone that works well on these things

-

yes. 200mm is the minimum. if its under that it must have a bash guard

-

Got my mrs to buy abag of cotton ball things , cut a few in half and poke them in the ear holes, seems to work pretty well

-

did they check the brakes on rollers? for some reason drum brakes and brake rollers dont go together, it seems to be a common issue on cars that stop perfectly fine, but fail on rollers i had a guy go thru wof check before cert, the car had a welded diff in it and still had a "brake balance problem", ha i wonder if its tyres or weight on each corner issues sometimes, one of my cars had multple goes at passing - shoes were fine, new wheel cyls, bled it a million times, ended up taking the guts out of the factory prop valve , nothing worked what solved it in the end was me sitting in the back over the side that was low, and that fixed it

-

Oh yes I have learned the hard way, anything HD related equals spending a lot compared to any other motorcycle brand Just because it's a caveman spec push rod 2 cylinder does not mean the prices of things that go with them are on the same level. Id suggest if you are keen on one, find one you either like in standard trim, or one that already has mods you want to do. When I bought mine, there were a few others that were around 15-18k that I liked, that had mods already done, I didn't want to spend that much , but by the time mine is done I'd be up there anyway. I really like it though, it's a load of fun.

-

Yes I had to do that with mine, run in with just the outer spring, then fit the inner ones after

-

What you are talking about doing is all possible, and can be certed, @RXFORD has covered most issues, I would add that you'd need to be careful of any arms fouling on the chassis, when you fit an irs in a car that wasn't designed for it, you need to run the suspension through its full range of travel to make sure things don't hit where they aren't meant to before the bump stops limit travel The rear shock mounts will need strength added, a strut brace isn't enough on its own , it will need diagonal bracing as well but that's something I'd need to see in person to figure out the best plan starting with a non modified subframe would be easier, as if you need to cut or mod a bit that's been strengthened that makes life harder What is your main aim for doing this? Are you trying to get it really low? Going to do track stuff? There are options to sort out camber on the standard rear end that might make life easier if it's just going to be a street car

-

Some euro vans are like that, and available to buy as a cab/chassis deal for making camper vans with

-

GVM issues would likely be your downfall there as far as building something you could put some weight on, unless you want to build a feather or polystyrene transporting vehicle

-

New grips and throttle tube arrived from murica so spent a while fiddling around with fitting those, because both side switch blocks had missing bolts and stripped threads in one side so there wasn't actually much holding shit on. Also the clutch side grip was loose and rotated like a throttle one which was yuck I ordered some new switch blocks off aliexpress but they were a bit chinesey so I fixed the threads in the factory ones instead Seat is a heap better, way easier on the bumular region, I removed the rear pegs because with the previous seat I needed to use them sometimes to take the weight off my tail bone but now do not need that. Like everything else on this bike they were made of heavium, things like the battery support bracket are amazingly hefty compared to what a Japanese bike would have Also swapped black plate on Am having a hard time coming up with a colour scheme for when I paint it, I don't want too many different finishes on it but would like something to break up the chrome/silver/black cause sometimes it looks like a black and white photo of a bike anyway, Heres a pic yet again in a picturesque spot, if you are getting sick of these pics, don't look below, ok

- 528 replies

-

- 15

-

-

So the old Ali engraved plates are still valid, if the car matches the description on the plate, mods are the same, then all good. Any new certs after Feb 2021 I think it was? Will be the new EDP donut thing Any car with an Ali plate that gets re certed for anything other than wheels only, gets a new donut one when it's re certed

-

Have had the results of a few online shopping sessions turn up over the last 3 days, and this was the main one that I was a bit excited about, and it took about 2 minutes to fit after I made a couple of alloy spacer/washers Slightly hard to find, because since purchasing this machine I have found its a bit of an in-between model that was only made in 04 and 05, the 06 on dyna is bigger and a lot more common so easier to find parts for in nz. 04 and 05 has a different tank so the earlier seat doesn't fit Anyway, my posterior is much more suitably supported, the vertical bit supports your lower back which is good

- 528 replies

-

- 15

-

-

Sounds like made up shit to me Let me guess He also had a land rover with a 186 from a gtr torana that would get rubber in all gears and keep up with a GTHO

-

A roll of itchy header wrap is pretty cheap so I got a roll of that before I read this thread again, probably should have bought some actual muffler packing Also should have tested things more scientifically , I dunno if it's quieter or not Meh. Also took the battery out and cleaned earths and power cables where they attach to improve starting, as sometimes it goes kerrrrclikclikclikclikKER KER KER POTATOPOTATOPOTATO and now that seems to have improved

-

OK so the packing did settle, but where it settled to is likely the road between my house and the Waikato area Turns out steel wool is not suitable as a packing for mufflers Also once the packing disappeared it discolored the coating on the muffler slightly I'll investigate a more suitable packing material

-

The threads protruding thing comes from the CCM chapter 18 That says that a bolt must protrude past a lock nut by 2 threads The reason for this is the first thread on a bolt is a bit smaller, so a nyloc or similar lock nut will not grip the threads correctly if it's flush. Unfortunately some of the requirements in the book don't fit every situation, and sometimes are misinterpreted or applied where they don't need to be Personally I would not require 2 threads past the face of a threaded part, as long as there's enough thread engagement in the part itself

-

Needs a hilux or similar ratty old truck cab adapted on to it haha

-

How much have you lost in total? I really like the level of commitment to making it lighter, and doing it the way you have, making trick parts like the carbon Fibre brackets etc I was watching something the other day about dudes in America who remove things like brakes and just have a single front disc for max top speed runs, and another one who had drilled holes in his brake lever so the wind pressure at super high speed doesn't apply the brake slightly

-

Yeah I would assume the ute itself would be good quality paint and clear, and the canopy will be made in nz and painted locally by the lowest bidder