-

Posts

37,282 -

Joined

-

Last visited

-

Days Won

346

Content Type

Forums

Downloads

Events

Gallery

Everything posted by Nominal

-

Pallet packing made me twitch too.

-

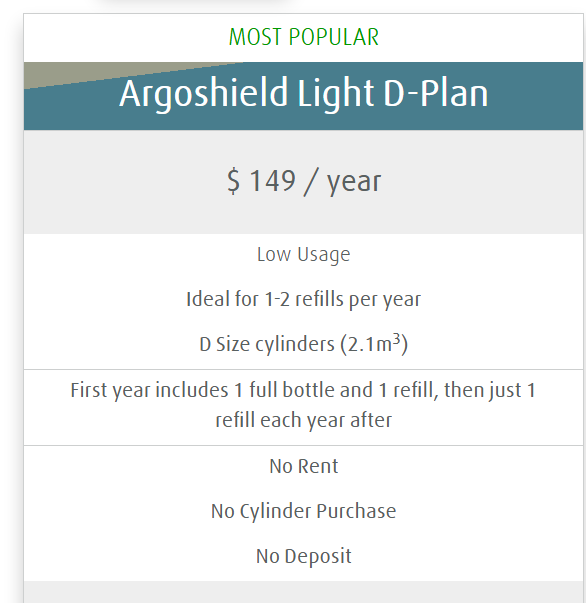

There is a lot more chat in the welding thread. If you really want the cheapest you'll have to do some legwork. I just go with the BOC D-plan coz easy, not big outlay to buy the bottle. Look at Bunnings too. e.g.

-

Hydrofluoric acid is nasty stuff, can go right through your skin.

-

Discuss here about Yoeddynz's little Imp project...

Nominal replied to yoeddynz's topic in Project Discussion

-

-

Get some new wheels?

-

Wylde's '84 Holden Statesman DeVille series II

Nominal replied to KKtrips's topic in Project Discussion

I know, I was just winding you up. -

Wylde's '84 Holden Statesman DeVille series II

Nominal replied to KKtrips's topic in Project Discussion

Isn't it supposed to go on the front? -

Fuel pumps don't seem to like sitting around after running in my experience. Which makes them a pain on project cars. Even worse if there is a bit of moisture in the fuel (from sitting around in half-full tanks)

-

Random slightly cool stuff you built but not worth its own thread, thread

Nominal replied to h4nd's topic in Other Projects

Is there any particular design, or just a firebox with a chimney? -

-

Nothing about the steering box could cause the discs to hit the control arm. The spindle that the wheel rotates on is constrained by the ball joints and the steering stop, so something must have movement/slop that shouldn't be present. Hopefully the mechanic did the check mentioned above rather than a visual inspection.

-

That's amazing!

-

Hey @skidmark, really good to see the substantial progress on this massive project. Thanks for providing updates here.

-

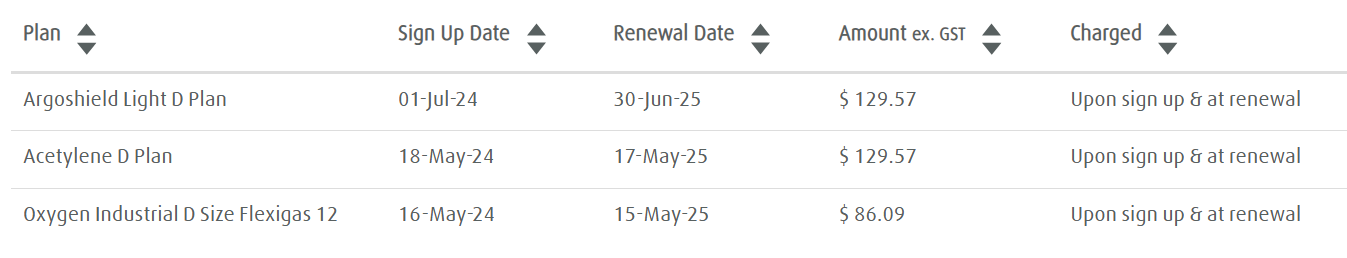

This is my BOC account, seems cheap? Maybe too cheap, I'm not sure. Their website seems a bit out of whack. This is how they list the D-plan for Argoshield.

-

Why not jam one of these on? https://www.bunnings.co.nz/diablo-165mm-6-5-48-teeth-steel-demon-ferrous-metals-circular-saw-blade_p6370900 The only issue I can see is that the works of the saw may not be well shielded from metal dust from grinding.

-

I'm waiting for the 89000rpm bit.

-

It's kind of old, but they approach is good AutoSpeed - Undertrays, Spoilers & Bonnet Vents, Part 1 AutoSpeed - Undertrays, Spoiler & Bonnet Vents, Part 2 AutoSpeed - Undertrays, Spoiler & Bonnet Vents, Part 3

-

K-Trips 1982 Holden Commodore VH Discussion

Nominal replied to KKtrips's topic in Project Discussion

Do you get much reaction / chat from the natives? Maybe some summer cars events coming up? -

Discuss here about Yoeddynz's little Imp project...

Nominal replied to yoeddynz's topic in Project Discussion

What kind of lunatic would embark on a project with a recipe like this??? -

You are probably right, I built my one just after 2000

-

When you reg it as a new one and get 1 year WOF's

-

Just putting these here for reference, photos etc from Ford's Iron Mountain plant in UP Michigan where the woodie wagon bodies were built until 1952 when Ford went all-steel and the plant closed down.

- 111 replies

-

- 18

-

-

-

Ouch on the steel price!

-

Yep, just out of Waihi.