-

Posts

3400 -

Joined

-

Last visited

-

Days Won

1

Everything posted by NickJ

-

Seriously? well keen on that, was planning on dropping the whole lot off to a fella I know with one, the finish is just awesome! There are posts about Nissan throttle bodies that strong cleaners rip a coating off, my interpretation was guys pulled the butterflies and never took care to seat them properly, giving the impression of a removed coating. how much do you have to strip down for blasting or do you just have at it?

-

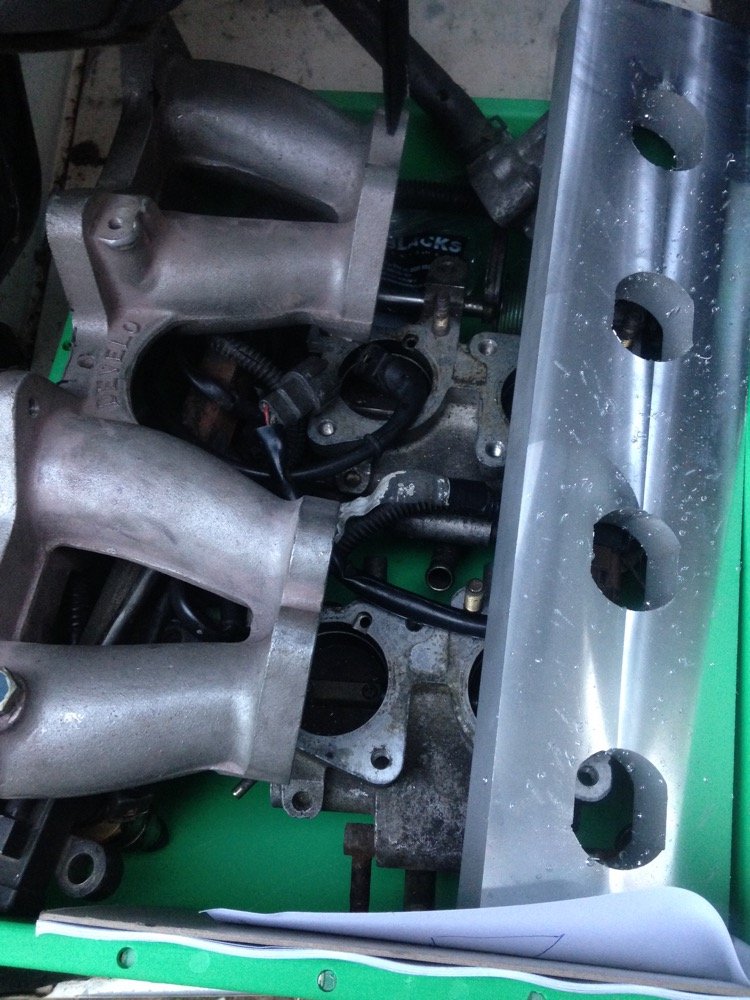

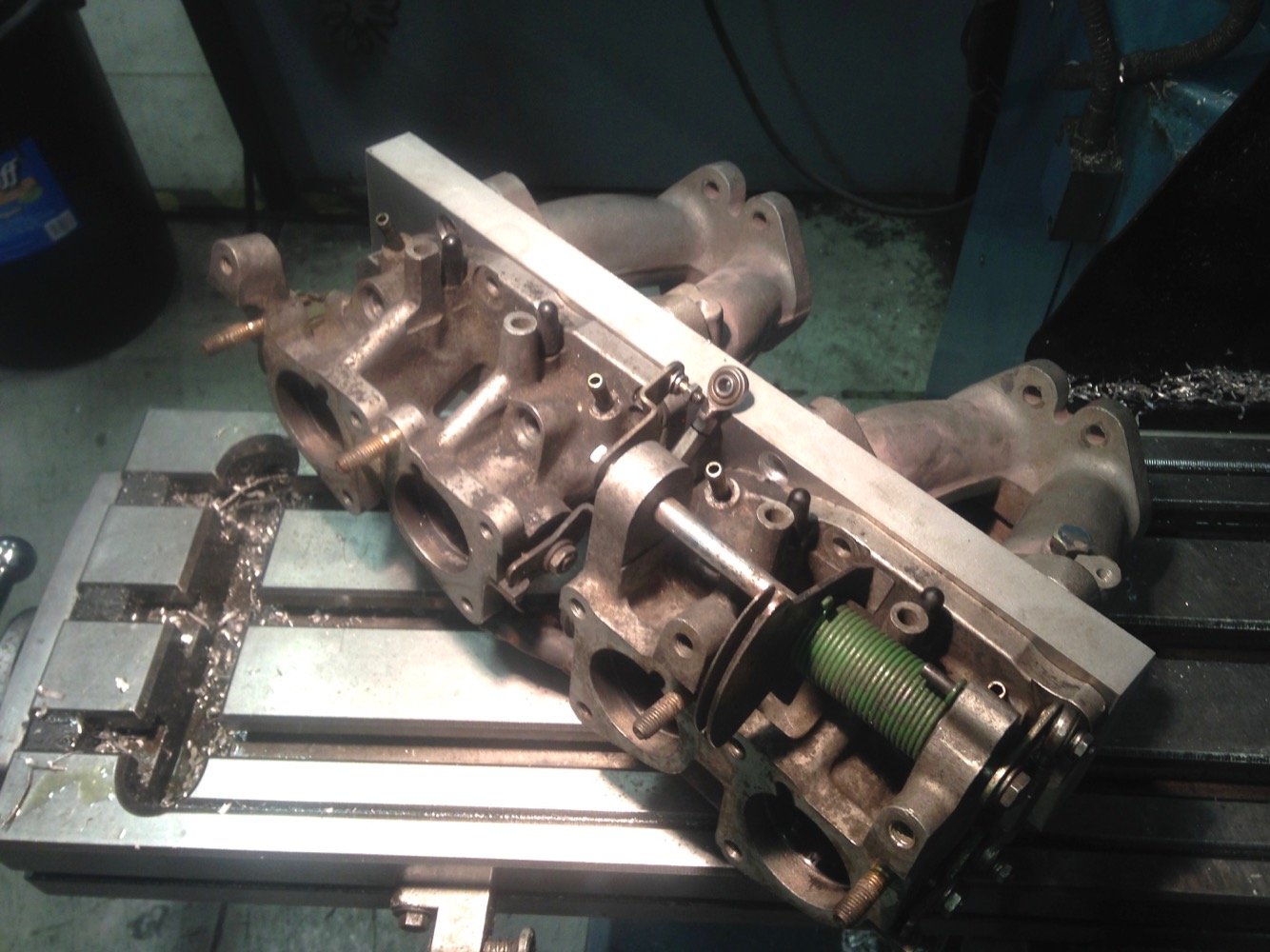

With COVID depleting the play budget, to keep my mind running I decided to finish the throttle body adapter for the spare motor, even though the cashflow is no where near rebuilding the motor, this is "free" progress for down the track Took the forgotten box of bits off the shelf and put it under my desk at work, currently aiming to knock off 1 hour each week until done. So far 2 weeks and 2 hours down, i've drilled and tapped in the right places so that everything bolts together, just need to port match and surface the throttle body side.... Love to have a mill at home, so far most of the hour is setting up! So cleaning throttle bodies, just like carbs, or is the internets claims of special internal coatings something to beware of?

- 53 replies

-

- 13

-

-

CHCH peeps, urgently required for peeping

NickJ replied to smokin'joe's topic in South Island Region

And it just pulled into the supermarket 3 cars over from me. Messaged you a pic, hopefully it is on your phone? Many tentacles has Mi-Oldschool -

CHCH peeps, urgently required for peeping

NickJ replied to smokin'joe's topic in South Island Region

I head out to macleans island a few times per week and live not far away too -

Thankfully everything on the inside is straight. I assume the capping is just held on by the rivets? Good link! spent hours trying to find decent aluminium panel beating videos and only got modern car stuff, that channel looks epic, will sit down for a watch over the weekend.

-

Thats well lame! Do the in lines project into the chamber? I run them down into the bucket cos I hate cleaning the inside of vac chambers I have wondered about putting a clear inline fuel filter by the pump, if resin made it to there it would wet out the filter element and cause massive flow restriction slowing further migration.

-

Keen to hear more about your experiences with shrinking and general dent removal, I have some deep small dents in mine from the PO i'd love to tackle but unsure if i'll just make it worse?

-

You may struggle to get it airtight without a solid gelcoat if vac infusion is the path you want. Any release film will do the trick on a good gloss paint finish, providing the paint has bonded well to the mould. I do wonder if the cheaper rattle can paints will soften under the epoxy, is that what you were thinking? No harm in running a test panel on some scrap.

-

I'm about to embark on a similar project, attempting to turn myself, this is the best info I found: https://www.nolathane.com.au/install_guides/Z5373.pdf Pacific Seals in Wellington whip up custom jobs, I can only assume that PU would be up their alley too.

-

A pic from Datsun Nats last year appeared on the internet, the bodyroll might be unsettling for some viewers... When I brought the car, dad dug out a sway bar and said I better have it to keep the car complete, on viewing the above photo I pretty much dug it out, stripped the surface rust and re-installed as soon as the paint was dry! While the brain was on suspension and handling, I lifted the bum to work out the origins of the "weird" rear end characteristics, i've always been unsure about the backend, if the road is just right, it feels to drag the car to the left. Setting up string lines, the alignment was pretty much spot on, maybe a bit too much toe on oneside, trailing arm bushes are also moving freely without detectable play. Best bet right now is the subframe bushes, they are not looking too happy and likely 50 years old, going to order some urethane and machine up a set as a starting point and go from there. Has anyone here experimented with subframe mounting, solid etc? keen to hear your results. So much for locked up for winter, went for a lap over the port hills to "check" the new rollbar, I can report i'm an idiot for not fitting earlier!

- 53 replies

-

- 18

-

-

Snow groomers have a radiator just behind the cab, only issue I had with them was the noise of the fan when it kicked into top gear.

-

I cringe hard on the thought that if mine does surface, every rust repair bodge known to man will be found and i'll be forever that guy.

-

Agree, so fucking nice! Parents had a SSS coupe when I was young and I ended up with a 4dr SSS as my first car, I sold it because the rust just got so horrific no volume of newtech could hide it from the wof man..... Hope there are no dodge repairs to discover and its back on the road soon!

-

Thats actually pretty cool using the barrel, do you already have that part? Mates machine has a chunky ballscrew underneath along the midline, linear rails at the same level, the work surface is then suspended from either end above all the moving bits. While its not that rigid (about 0.5mm deflection if you lean on it) it does keep the dust well away from all greasy bits.

-

What basic design are you going for? helped a mate set one up a few years back of similar size, the weight of the gantry would be hard on belts? he went for ball screws, we managed to drive it pretty hard, lost precision well before we got any whip out of it.

-

they have a min turn radius that will dictate idler size

-

warm some in a cup with a heat gun to 20-25C and you'll find another world

-

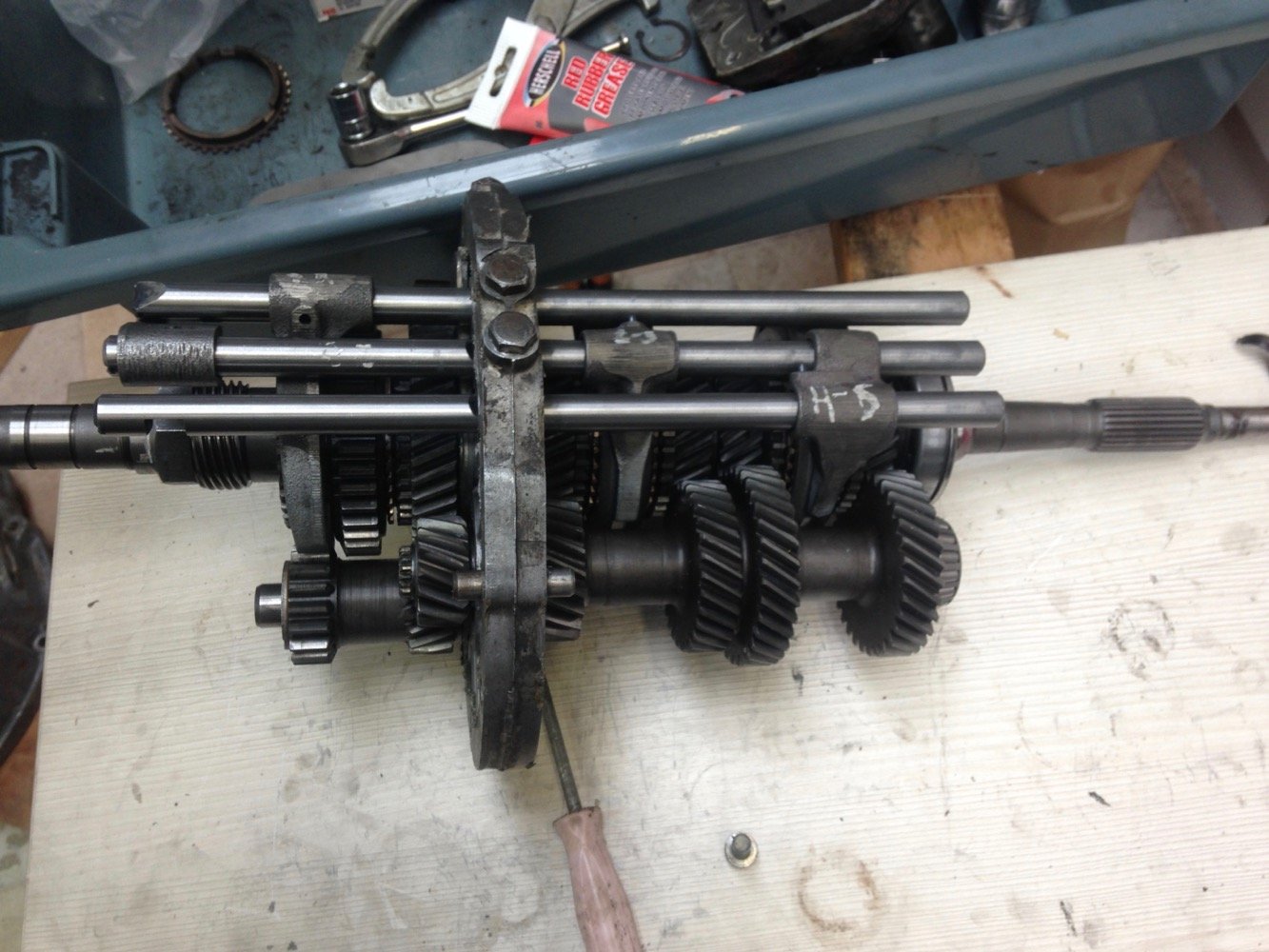

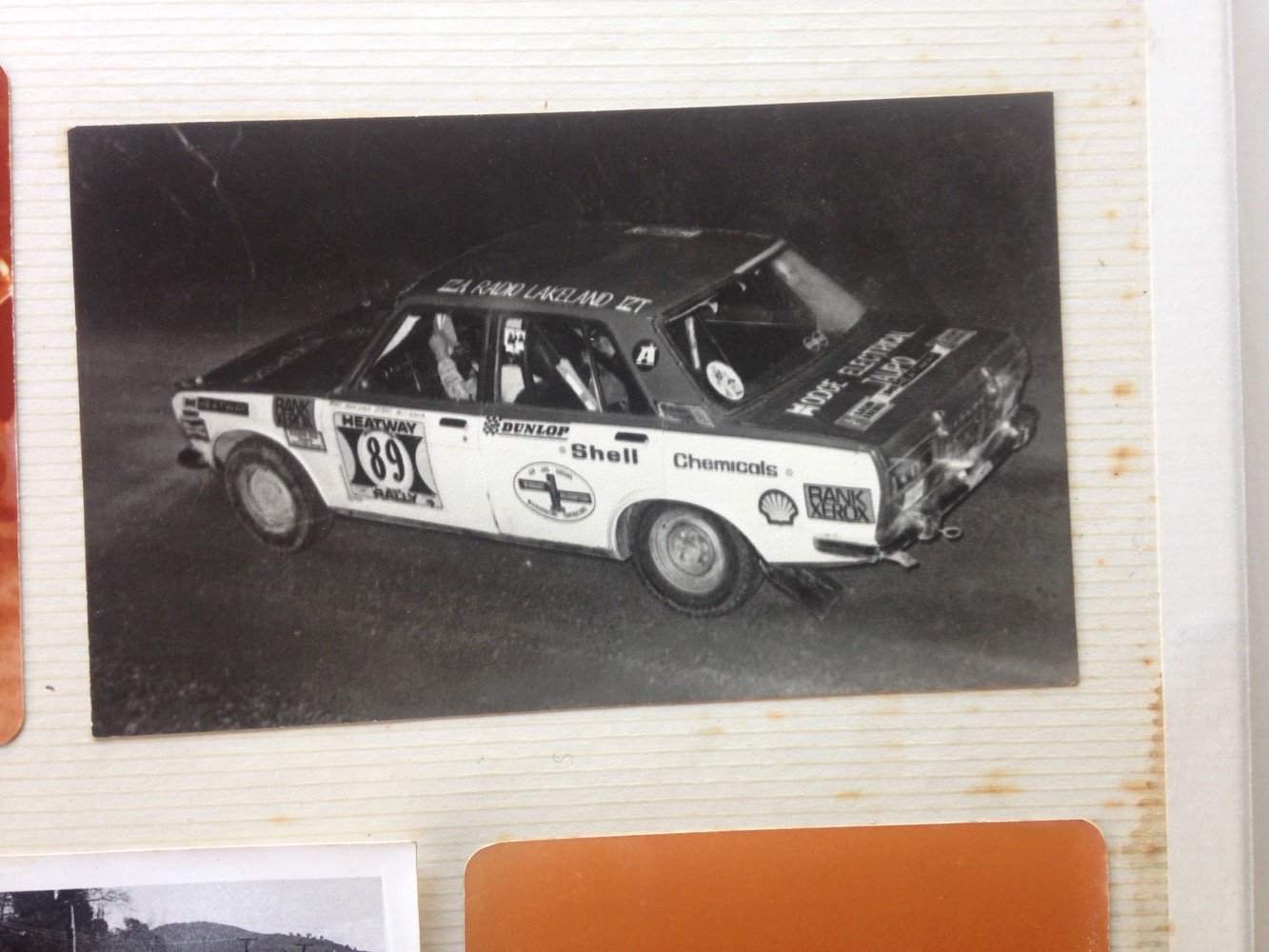

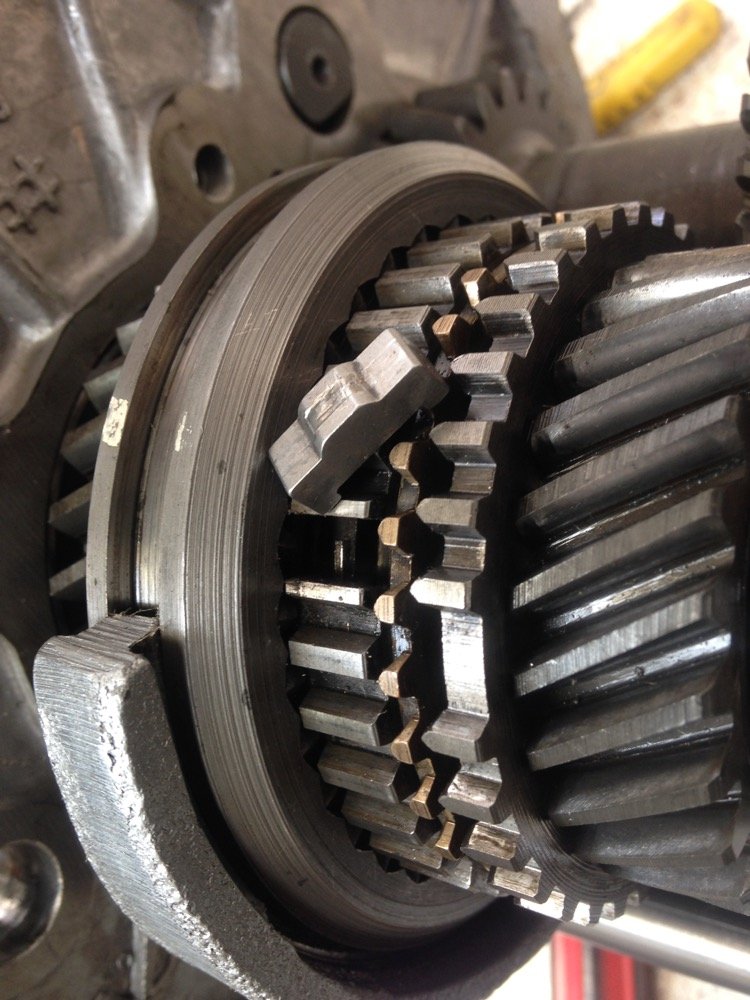

Welcome to the New Year Datsun thread, year of the dogleg.. Work on the new motor stalled due to Christmas break and needing funds for a special Datsun event - Leadfoot 2020. Mid last year I made a few sneaky phone calls and managed an invite for my father to compete in his 1975 Heatway rally car that has been resurrected. As the story goes, a few weeks out from the event, his co-driver convinced Wishart Helicopters (Now Helicopter Line) to sponsor their entry, they stripped the running gear from Dad's 68 1600sss, swapped it into a bare shell and had at it. With only a few pics and good stories left I figured he needed a good event to bring the car out for the first time. While he wasn't near the top of the impressive field of entries, the car ran, sounded and looked the part, We had an amazing weekend which made all the travel and preparation worthwhile. With lockdown now in effect, the motor build is well and truly on the backburner, like alot of NZ, surplus spending is a luxury so i focused on what I had in the shed. This gearbox really tested my patience, advice given was to test everything before fitting, the linkage bellcrank is a tricky beast, it however, was a breeze... This little shi(f)t insert was the source of my pain. Every time I put it together, these would fall out of second gear synchro. Somehow I was slow to learn that the front cover acts as a travel limit for the shift rod, once installed, no problem. Once the box was together and shifting nicely, I popped it back (if only it was that easy on my own!) first test drive and it really did not want to shift 1-2, so out it came (Again) Issue was tracked to the spacers on either side of the sandwich plate bearing, swapped them over, and everything lined up much better - thats the punishment for many months between strip and rebuild! The only saving grace was carpet on the workshop floor, made life much more comfortable. Final lockdown task was cleaning up the centre console from the 200sx the gearbox came from, hot soapy water and plastic doctor, very nice and suits the care 100% Test drive was short lived with a squealing alternator belt, but proved the gearbox was happy, this morning I swapped out the belt for a spare and went for a quick drive, while it ran terribly, a tank of fresh gas brought her back to life. And that brings us up to tucking the car away for the winter, fingers crossed for some pottering about this winter, getting ready for a spring time hoon!

- 53 replies

-

- 17

-

-

-

You pretty much called out the weld quality on day one #Nostradamus

-

Thats the kind of rookie code I was expecting, if anyone else is actually reading this thread suggestions like this will help them along. In hindsight its obvious arduino has a rescaling function and would tidy up the code nicely. I also agree that doing that maths in the computer makes more sense. One of my original ideas was to make a blackbox DAQ to hook up and run on all sorts of projects, I guess it comes down to which end someone wants to program at each application, or code in a menu to set limits?

-

So sweet it runs, good motivation booster I hope! I wouldn't get too hung up on the idle just yet, side draft + points? never really go together nicely, the way it jumps off idle suggests nothing major is annoying it.

-

Could that run 2 or even 3 inputs? how big is the screen? thats super handy, does what I achieved with my laptop without the hassle

-

So awesome! Looks like progress is moving at a motivational speed?

-

you must be near the only one on this planet who manages to capture all the right things when for the rest of us, the one bit of information that would be useful is the one that we didn't.

-

Resin cold, part warm is standard logic, just a pain with de-gassing in the middle, gotta watch resin bulk so the temperature doesn't get away on ya. If feasible, take lots of temperature readings for future reference. With post cure, the part needs to be fully supported, in the mould is best. The theory is to ramp up just behind the advancing HDT so that the part never suffers any major loss in rigidity. Very simply, the higher HDT is from increasing cross linking, if the part is ramped too fast, the cross linking can occur in a distorted part, never to return to planned dimensions. From a similar viewpoint, uneven heating can do the same, either ramp real slow or get a big fan in the box to ensure low temperature gradients. Mould choice is very limited if you want to post cure to 120C, MDF shouldn't go past 60 (bad smells...) Normal resin moulds tend to turn rubbery but with some experimenting and cunning it can be done.