ajg193

Members-

Posts

7429 -

Joined

-

Last visited

-

Days Won

1

Everything posted by ajg193

-

Wants to hold centre more than it used to though, kind of like a modern car

-

It's driving absolutely perfectly, self centres and no play

-

I decided to give Amayama a go for ordering a part. The Starlet has always had a bit of a clunk in the steering, a few years ago I narrowed it down to the internal bush on the drivers side having a small amount of play. I then promptly did nothing about it due to the part being expensive. Checking on Amayama, I could get the part for $32 including GST and delivery. Toyota wanted $135+GST. the part arrived after a three week journey from Japan. I pulled the rack out of the car, 1960's British car engineers really need to take notes on how to design something. It's stupidly easy to remove the rack, they even make the bolts go in from the bottom on the side where the engine is in the way. I then stripped the rack down and removed the old bushing. The bushing was quite difficult to remove, I ended up heating it slightly and managed to hammer the inner section out with a long piece of pipe. I then ground the outer section out. The bushings are four layers Steel->Rubber->Steel->Teflon. I think the part cross references to a whole load of different models and is still easy enough to get. I then had clean, grease (lithium base molybdenum disulphide) and reassemble the rack. Setting the preloads was interesting. I ended up setting the main pinion depth by feel and used a kitchen scale with a 17mm socket attached to it to push on some vise grips to measure the turning torque for setting the rack guide. I ended up getting it right at the middle of specs so I threw the rack back into the car. It took a couple of tries to get the steering column aligned on the right spline - first the steering wheel was one tooth too far to the right, then it was one tooth too far to the left and finally it was bang on. I took the car for a drive to test it all out. I'm actually blown away by how different the car drives now. There is no more clunking at all and there is no more twitching, and the tracking doesn't change slightly under heavy cornering. I always thought there was something up with the rear suspension but it handles perfectly now. The steering actually feels like something modern. I'm guessing a fair bit of the change in feel is from adjusting the rack guide. Either that or I've just tightened it too much and the rack is going to wear out super fast. Oh, and the other week I was doing a bit of thermodynamic modelling to try and improve the intake air temperature prediction, details and results are over in the DIY EFI thread. The engine behaves a lot better now, nice and smooth around town at low/mid loads.

- 90 replies

-

- 18

-

-

My brother has one on his 302 Capri, been on for a few years and I don't think he has had any issues. But he's probably only done like 5000 km in that time

-

Random slightly cool stuff you built but not worth its own thread, thread

ajg193 replied to h4nd's topic in Other Projects

Pretty sure old Shayne Gooch the lecturer was jizzing over that golf ball hurler design about 5 years ago when we had to sit through his class -

Gilmers are only ever acceptable when used on a 4k with a 3/4 race cam.

-

cylinders are like $5, just do the whole lot

-

The proportional term on megasquirt doesn't actually work like in that video though. Instead of being P = Kp*Error, it is P = Kp*(currentError -lastError) Basically, with megasquirt, Kp doesn't really do anything on its own and requires one of the other terms to act on the system and initiate the changes. I've gotten it to respond well enough again by setting integral, then adding proportional to speed up response and then going back and forth between the two to balance it out. I have stayed away from derivative gain for now. Kp=30,Ki=10 are the values that give a reasonable response on my setup. Probably around the same as the values I would have had in it before I decided that historic me was stupid and current me could do a better job of turning knobs. In all the other PID systems I have set up/made in the past I used the traditional algorithm that allows setting of proportional first and then fine tuning the offset out with integral and then damping it all with derivative.

-

/* This math is the derivative of the ideal PID equation: * output = bias + ((P*error) + (I*errorsum) - (D*derivative)), but with * P and D only using PV and not the error (or setpoint) to help avoid * overshoot once properly tuned */ deriv = PV - (PVarray[0]<<1) + PVarray[1]; Kp = ((long)(PV - PVarray[0]) * flash4.egoKP); Ki = ((egoerr * (long)flash4.egoKI * (long)looptime) / 7812L); Kd = ((deriv * (long)flash4.egoKD*781) / (long)looptime); PVarray[1] = PVarray[0]; PVarray[0] = PV; *egostep = (long)((Kp - Ki + Kd)) / (PID_scale_factor); Turns out that MS doesn't use Kp to correct the AFR based on error, just based on how much the value is changing? Recommended routine is to tune integral term and then adjust the proportional and derivative terms later. Supposedly a "Type C" PID control algorithm and more stable than the basic "Type A".. I'm gonna have to do some learning.

-

I've spent some time digging through the source code, looks like they are actually including VE in the flow calculation, it's just that TunerStudio misrepresents it. Another issue I noticed is that the EGO control routine seems to have some sort of a bug, where under certain conditions it does not actually aim at the correct AFR. Ie at 1200 rpm and 30 kPa, it is set to 14.7, but the EGO routine is trying to pull it to like 13.5. I have no idea why and can't figure it out.

-

Other problem is a stinking hot exhaust manifold right under/next to the intake manifold. Without a heat shield. I don't have enough room by the chassis rail to space the exhaust out any further from the head - do phenolic gaskets even cope with exhaust at all? Heat soak with the engine off is almost a problem with my setup, I aim for idle to be 13.5ish:1 under normal conditions as if the engine is sitting for like 15 minutes and then turned back on it will idle at like 15:1 (it idles reasonably well up to about 15.5:1) for a few minutes or you drive a hundred metres or so to pull the heat back out of the manifold. This is even with the CLT correction factors, so it's probably a mixture of injector/fuel heat soak and the possibility that the hot exhaust causes the intake to be hotter than CLT.

-

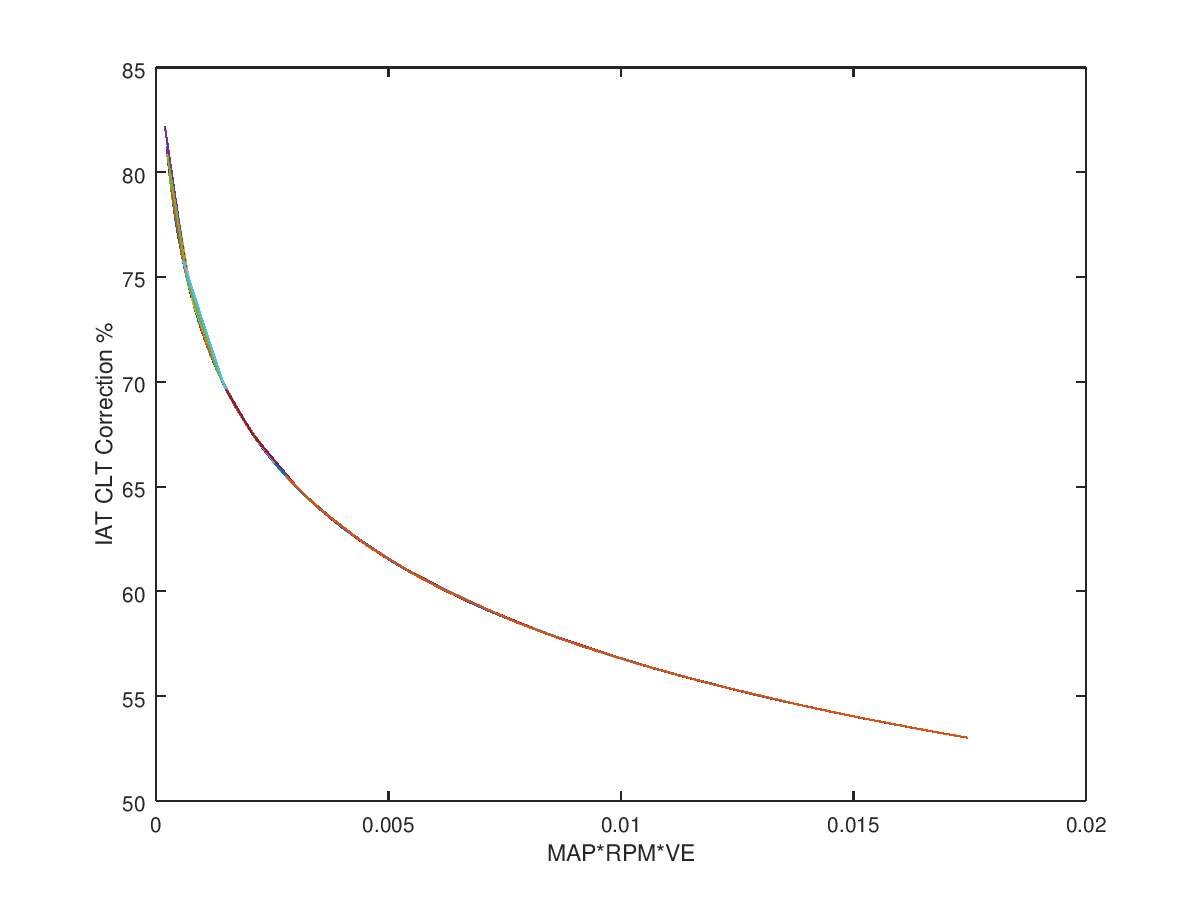

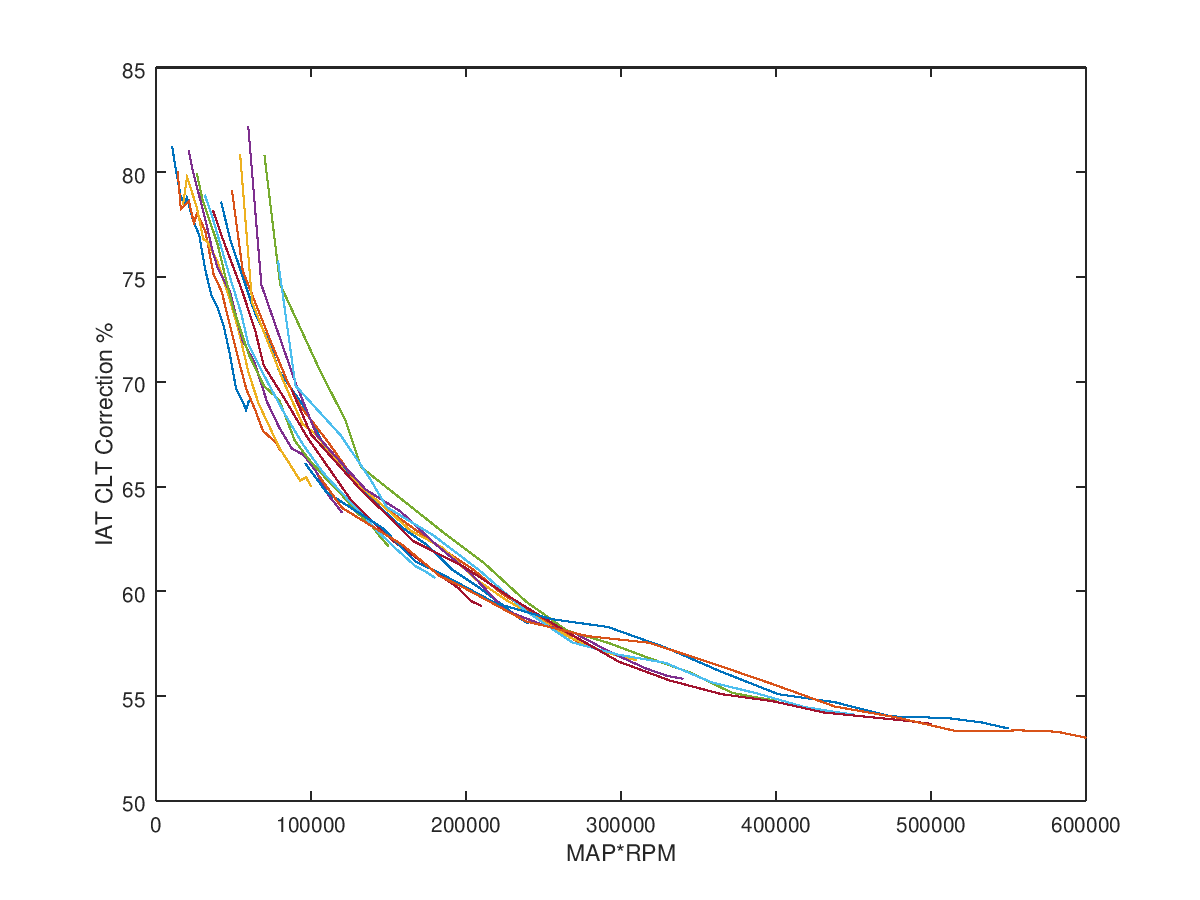

Due to the location of my IAT (airbox) sensor on my setup I have always had a little bit of difficulty determining the actual temperature of the air when it gets to the cylinder. The engine has long steel intake runners that heat up over time, affecting the heat transfer. I could theoretically rip the manifold out and weld a bung on to put the sensor right near the head but this would not look quite as per how Toyota would have done it, and Toyota made millions of cars with air temperature sensors in the airbox anyway so it's theoretically possible to make it work well. Symptoms of incorrect air temperature prediction are leaning out as the IAT increases when idling, AFR changing as the engine is heating up to steady state, AFR bouncing all over the place at certain RPM/load conditions etc. A fix for these issues is to use an IAT/CLT correction factor that blends to two values as a function of air flow rate to predict the actual temperature. The most common approach is to set the correction factor to near 100% at idle conditions and then the rest is just determined through trial and error and just forgotten about when it's determined to be good enough at steady state. One problem with this setup is that the model uses RPM*LOAD to predict airflow and doesn't care about VE at all, which causes large errors at low load conditions where VE can be less than 50%. I don't believe that this can easily be tuned out. Anywho, what I recently did was pulled out my old thermodynamics book and opened the section on convection heat transfer into fluids flowing in a pipe. I used GNU Octave to develop a simple model of the intake system and engine and generated a surface map of predicted correction factors for all points in the engine tune map. I can adjust intake runner diameter, runner length, engine capacity, runner temperature profiles etc. The model uses the VE table from TunerStudio to calculate actual mass flow rate at each point (technically this model will cause the VE table to change, so some iteration may be required for more improved results). A collapsed output from the model is shown below, giving the expected shape of the curve for my particular engine (I still need to actually measure the temperature of the runners at various points to confirm). I've put the predicted curve into TunerStudio and the engine no longer hunts when you sit there holding the engine at around 1500 rpm with no/low loads and the AFR seems to stay constant for a wide range of IATs now. I don't know what can really be done to fix the AFRs being somewhat all over the place (ie being 14:1 when the engine first gets to 85C but slowly changing to 14.7:1 as the runners heat up, with constant IAT) as the engine is warming up to steady state apart from adjusting the warmup enrichment curves. We see the limitations of the megasquirt correction factor when we compare the results of the MAP*RPM model vs if we include VE (x axis is mass flow rate, kg/s - below). At low load conditions there is a broad range of correction values for each MAP*RPM condition, which results in a large uncertainty of what the actual correction should be. Perhaps I should look into playing with a MAF sensor one day, but there isn't really any room left for me to fit one in the engine bay without making it look out of place. Side effect of the model is the prediction that if I cut the length of my runners from 650 mm to 250 mm I could increase my power by 6% by dropping the temperature of the air getting into the engine from 57C to 38C at the upper RPM range. That could be a good excuse to make a dual runner system with a butterfly valve that swaps them at a certain RPM in the future.

-

Those pens are literally rubbish

-

Also, how much earth turning power is that putting down to the rear wheels?

-

I hope that is running a 63/64ths race cam

-

povo 4 speed or 5 speed? Was a friend's car with low suspension. I don't even need to jack mine up

-

Somewhat related Barry sharn: You can't fit a gearbox to a KP starlet if you jack it up on one side only, the body flexes enough that the bellhousing fouls with the tunnel before you can mate it to the flywheel

-

You think you're too good for bog? If it was good enough for your dad it's good enough for you. /Barryrant

-

CRC Tyre black. Goes on with a rag or a brush if you're rich, soaks straight in and lasts literally years. I did my starlet bumpers about 5 years ago and they still look like new. Doesn't streak or anything.

-

Is that running a big boy cam or is it just running like shit?

-

You gonna visit me on the way over? I can fill your boots with RF tranceivers, will keep the 5G/Covid away

-

Car batteries are super recyclable, one of the most effectively recycled items in the world. That's why they are still allowed to be made of lead. Unlike circuit boards, they end up getting burnt in Kenya

-

Bloody bureaucracy I tell ya. Time to drive all our old cars into the city and protest

-

Just put side draughts and a 4K distributor on it if you don't want wires everywhere. Pretend it's a rally 4age in the 80's