-

Posts

856 -

Joined

-

Last visited

Guypie's Achievements

Post Fiend (4/5)

1.6k

Reputation

-

Guypie started following Roman's 4GR V6 Toyota Carina and Shrikes Will it ever be finished Toyota Levin AE111 AWD

-

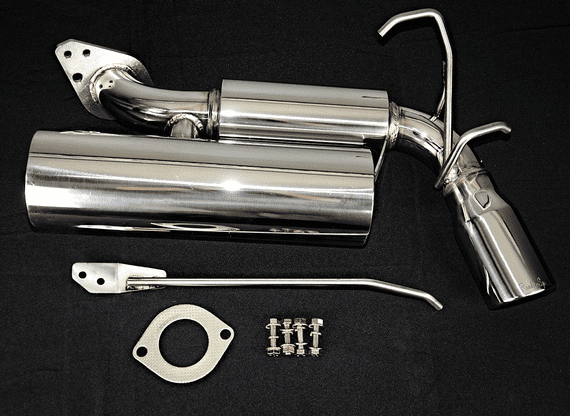

If it's one particular frequency you want to eliminate you could do a heimholtz resonator/j-pipe thing. I think it moves the frequency up or down by an octave Calculators here: https://strikeengine.com/helmholtz-resonator-calculator-exhaust-j-pipe-length/ An example of one:

-

If I wanted to change the wheels on my certed car with the old data plate cert, is it a full recheck or $50 re plate fee or something in the middle or both? LVVTA website says this but I can't quite make sense of it. "The fees charged to a customer for LVV certification are derived from the time it takes to carry out the LVV certification inspection(s), fill in the required forms and form-sets, and prepare the associated documentation, which will be in the region of 2.5 hours for the more straight-forward certifications like a seat and seatbelt installation, through to 4.5 hours for a Targa car, plus in every case $270.00 for the certification Electronic Data Plate fee (subject to change), or $50 plate fee for a wheels and tyre change only certification (on an already certified vehicle), and additional consumables including stationary, courier, telephone, and travel expenses." Too many damn commas in that sentence. Data plate currently says OE wheels, was hoping it would say 17x7 40p or whatever so I could swap to something else of same spec. Edit: just found this, my exact question: "My car has been certified for coil-over shocks but on the stock wheels. Now I want to change my wheels. Do I have to get the car recertified? Yes, you’ll need to get the car recertified, but providing that all other modifications match what the vehicle was originally LVV certified for, you can get a partial recertification for wheels and tyres. Simply give your LVV Certifier a call and let them know what you want to do. The cost is up to the LVV Certifier to determine as it will depend on how much time is involved in the inspection and LVV certification process"

-

-

I might have some new spokes in the right length. Let me know how long they are and I can probably hook you up.

-

I know that a friend got his coregas or eziswap bottle filled by gaspro in Hamilton when no swappas were available. Doesn't look like they have a welly branch though.

-

They aren't updating stock on the Bunnings website from what I can tell. Give them a call and ask, I got some argon from my local the other day and the one on the other side of town had mig gas.

-

Yeah CO2 bottle here. Would trade again, have been running it about 8 years now. Lasts way longer than mig gas per fill due to storing as a liquid.

-

How's the ring gap? I have heard of ring gap closing up when pistons get hotter than intended from the factory setup then wedging in the cylinder. Maybe it happened at tdc and the rod yanked the bottom of the piston off. Probably unlikely but another thing you could check on the other pistons. Maybe do some maths with thermal expansion coefficients and see if it would be likely to close the gap in the temperature ranges it could be experiencing.

-

I didn't really give it a big test run before paint like the first 2 bikes, I don't think there will be any issues so I decided to paint it after spending about an hour or so riding it around the house doing bunnyhops and generally messing around. I painted it GM beechwood medium fading to GM beechwood light, a very 80's metallic colour. Pretty happy with how it came out, its far from perfect but its straight and shiny and looks very purposeful. Now I need to get some good tyres for it and go do some shuttle runs! ... it might be a little while I think I might have cracked a rib out riding on friday hahaha.

- 102 replies

-

- 13

-

-

-

-

So for bike number 3 I decided that my previous 2 bikes were far too practical and that I need to make something that is almost useless. Well not really but thats is pretty much how it turned out. Most of the design decisions were made for 2 reasons. First reason is that I wanted to make a bike with as short a chainstay length as possible as that has a few advocates in the frame building world. I'm not convinced and think that it should be a ratio of front centre to rear centre, so if the front gets longer the back should too to maintain a neutral weight distribution between the front and rear wheel. But I don't really know so I figured I would make a long bike with a short rear end and see how it rides. Second reason is that I wanted it to be cheap and use as many of the parts that were already floating around in my shed. So it has a few odd standards that will make it ineligible for further upgrades in many ways. I had a single speed setup in the stash and sliding dropouts would be easy to make at home and allow for chain tensioning. I had a spare 26" wheelset from a dirtjump bike that I had built up then decided I didn't really like and then sold off the frame, so I made it to suit this wheelset with a 10x135mm axle. I made a chainstay yoke out of 25x6 flat bar with a couple of bends and the dropouts are from some 6mm plate. After putting all the parts in the jig its a just a game of connect the dots. So much easier! there are still some processes with getting tubes mitred that I need to make tools for, particularly the seat stay to seat tube interface. It intersects at an angle on 2 planes so I really would like to make a jig for the seat stays so I can just pop the mitering jig in the milling vice and get a nice clean cope. that is probably next on the to do list after building @hampie a bike. I made a reducer to go in some straigt gauge 31.8mm tubing to fit a 27.2mm seatpost. I slotted it on the mill with a tiny wee endmill spinning at 4000rpm. that was quite exciting but it came out pretty well I think! I borrowed @Geophy's bramley bender and had a go at bending up some seat stays. they came out ok, a little wrinkly on the inside. Probably could have done the packing with sand or ice trick. I mostly covered it up with a little brace that I was super happy with, I recon it looks cool.

-

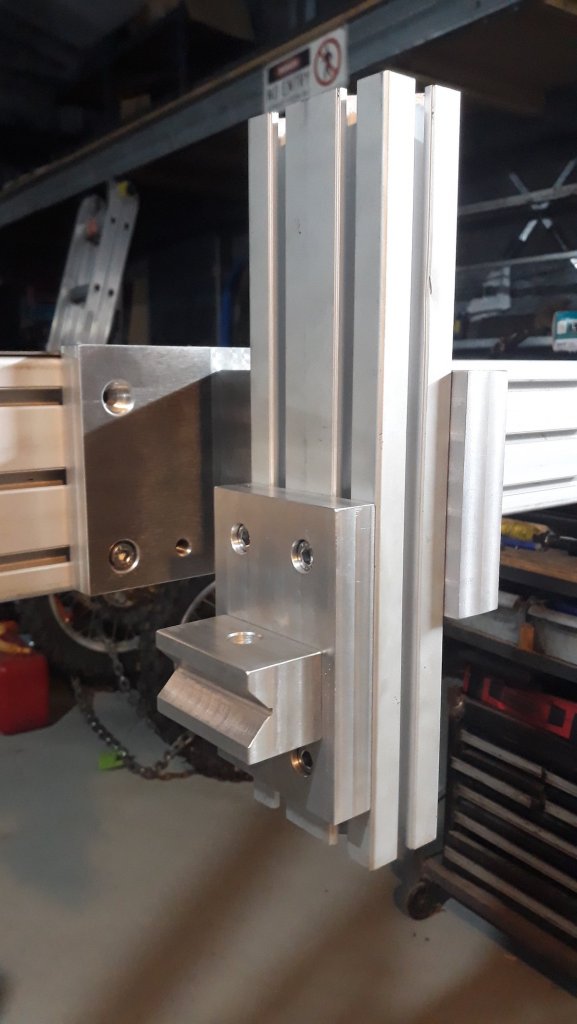

After the great success of the Llama based seat post alignment tool design I decided that maybe the dummy axle holder would work well if it looked like a duck. With that done a dummy axle and clamp followed shortly after And that is the jig mostly done. Certainly done enough to make a bicycle with.

-

Next I made a small legless llama another L bracket thing for centring the open end of the seatube. Almost immediately this happened: Wow a jig makes life so much easier. that front end went together in a matter of 3 or so hours without even trying to be efficient. Bike number 3 was underway and the jig wasn't even complete!

-

I didn't take photos of all the steps but here's a few of the highlights. I started off by bolting a 4080 extrusion to a 40120 at right angles for y and x axies (axises?axes?) and milled an arc into some plate to make the head tube angle plate. then milled and bolted some L shapes together for the headtube standoffs with a cone on the top end for centring and a stepped platform on the lower to make it easier to measure the lower edge of the headtube. I figured the lower edge was more important as fork length is more critical to the frame design vs stack height which is usually adjusted to suit the rider with stem choice/headset spacers/bar rise etc. The L brackets have alignment dowels to keep them in line with the t slot underneath. Seat tube plate was basically more of the same though I simplified the design a little with a horizontal slot instead of an arc.

-

The paint job is a 3 tone fade, mazda starlight silver>1988 GM corvette gunmetal grey>black topped off with 2k clearcoat. I prettymuch use the bike like you would use an enduro bike since it pedals pretty well and it has been getting regular use up Pirongia. Anyway, since then the bike building shannanigans have been ongoing. I decided its finally time to make a jig since the milling machine is now available for use, so I ordered a slab of ali plate and some extrusions and got stuck in...

-

Finally got round to taking some pics after the paint job on this bike. Also, a few spec changes. Got an old boxxer WC and a fox van rc coil shock, both solid upgrades. Bicycle rides very well, life is good. Also made a 3d printed chain slap prevention thingee, its a bit ugly in yellow so I will probably redo it in a silver at some point cause I have some silver filament now.