-

Posts

1005 -

Joined

-

Last visited

About Kiwibirdman

- Birthday 08/07/1968

Profile Information

-

Gender

Male

Converted

-

Local Area

Auckland

Recent Profile Visitors

1928 profile views

Kiwibirdman's Achievements

Committed (5/5)

2.5k

Reputation

-

Your plan should be OK. I wouldn't bother with the resonators, straight pipe through to your 2 into 1 muffler. The length of the tail pipe can make a huge difference. Also the number of bends. My Silverado has a side exit exhaust with a 140 degree bend out of both mufflers to get the side pipes in the right place. This is quieter than the previous tail exit with bends of no more than 90 degrees with the same front pipes and mufflers.

-

Perfect topic for a H series Holden Barry like me.

-

First to answer the questions. All 6 cylinder Holden motors share the same bell housing pattern, so swapping the 173 for a 202 of any vintage is a bolt in. The CNG fill port is under the bonnet as part of the pipe work. I had an HJ ex taxi on CNG and my grand father had his Austin Princess converted back in the day. The all filled under the bonnet, LPG had the remote filler. My first Holden was HQ sedan, 202 and factory Tbar auto and bucket seats. Pretty flash in the day. That got a 253 swapped in one weekend when the 202 and auto got worn out. Also had HQ ute, 308 and auto, would run mid 14s down the strip, HJ ex taxi, HX wagon, HZ sedan. Awesome vehicles, wish I still had the last HZ. My step father had a HQ wagon that got a celica 5 speed. I also put power steering in it. Good car to drive. Power steering is possibly one of the best upgrades to make them nice to drive.

-

I have had stuff done by diffsrus and always been very happy. I sent a mate to diff specs and he was very happy as well.

-

Adoom's 1975 Reliant Scimitar. Discussion.

Kiwibirdman replied to Adoom's topic in Project Discussion

The scimitar is pretty light to start with, under 1200kg, so even with a standard alloytec that car is going to fly, -

Adoom's 1975 Reliant Scimitar. Discussion.

Kiwibirdman replied to Adoom's topic in Project Discussion

Mate had one of these back in the late 80's. Went pretty well with the heavy old essex v6. Should be a weapon with the Alloytec, and a fair bit lighter. -

I wouldn't count on the VIN in carjam being right. Plenty of mix ups when cars got registered years ago. Not too hard to see a badly written 8 being turned into a 5.

-

-

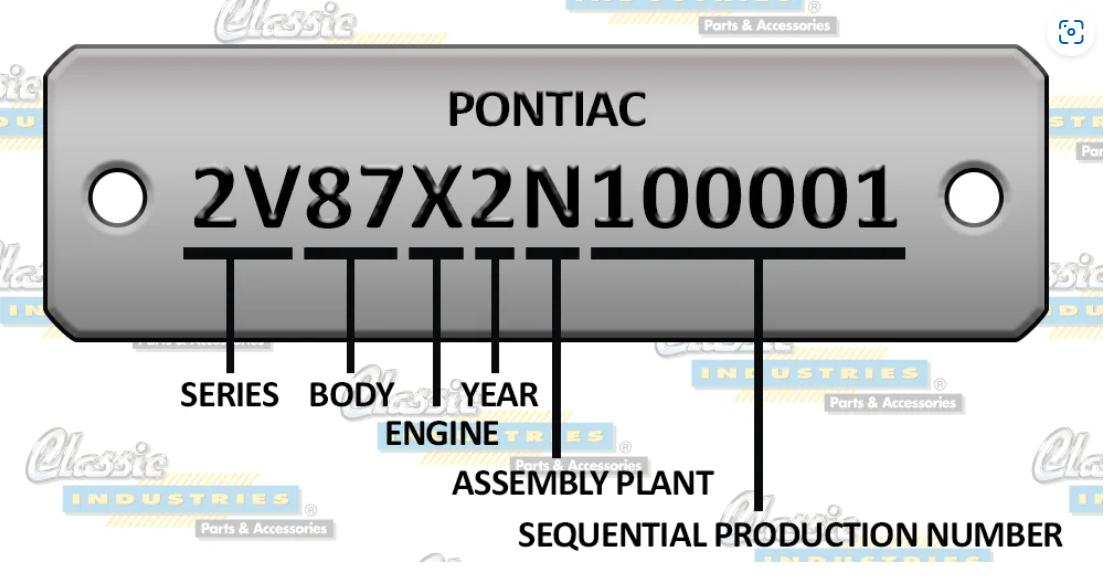

Cool car, I am jealous. It is definitely not a 1975, it has the big back window which came out in 1976. You can decode the year of the car from the VIN number which is on the top of the dashboard, there are web sites where you can put the number in and it will decode. The great thing about 2 gen F-Bodies is just about everything is available for them. I have bought a lot of stuff from Classic Industries for my 1st Gen. Looking forward to watching the build.

-

Kiwibirdmans 1968 Pontiac Firebird Convertible

Kiwibirdman replied to Kiwibirdman's topic in Projects and Build Ups

I finally took the car back to the painters for the final buffing. Happy would be a major understatement. I have never had such a nice looking car before, I have to admit driving it around after picking it up freaked me out, far too nice. Last night I put the badges on, which changed the way it looked again. I still have the wheel arch trims to go on. I don't think it was a bad thing to leave it for 15 months to let the paint go good and hard. Many thanks go to Dan the painter at Trevor Hanson Collision Repairs who did the paint and final buffing. Off to Americarna at the end of February. Still have a few things to sort out, need a boot around the gearlever, exhaust is hitting somewhere in the back.......always something to do. Big sound system to drown out the noisy EFI pump. Also the starter decided to not work when it was hot. I got stuck at a burger place in East Tamaki on Christmas eve. Lucky manual so could bump start OK. Went home and ordered a reco one from Rock Auto. Turned up 4 January and cost $190 sitting in my garage. Anyone want a works when its cold Pontiac starter, big and heavy enough to be a mooring for a good sized launch, free to a good (or bad) home.- 14 replies

-

- 15

-

-

-

La Viva 71 started following Kiwibirdman

-

SUGGESTIONS/RECOMMENDATIONS FOR VIVA CONVERSION

Kiwibirdman replied to La Viva 71's topic in Project Discussion

Thinking about going the v8 route, something that I have thought about a few times in an HC, there are a few options. Rover 3500, Small Block Chev, 308 Holden, Chev LS They were sold in South Africa with a 302 chev as a Chevrolet Can Am. A weapon from my research. I like the 308 holden, especially the late injected ones, as they are a RH drive motor so more space on the drivers side. I have been led to believe an LC/LJ torana front end bolts into the cross member holes with a simple pick up for the rear mounts that a viva doesnt have (There is a HB viva wagon around with a LJ torana front grafted on, all the body lines line up). That would sort most of the front issues, HQ Holden rotors with HZ calipers can be made to fit easily. Good luck finding one. Almost anything decent will require some surgery on the trans tunnel, and possibly the firewall. And some sort of stronger diff, Hi Lux might be narrow enough. My mum bought one new in 1973 and I have always like the shape, They just need some decent wheels and more horse power. Always happy to help others spend silly amounts of money and all their spare time. -

That is the plan. Its a 2wd.

-

Good advice. Yes my truck has the bolt in bearing unit. I like the stance of the truck as it is, not so keen on the not legal lack of travel. I think I will start with some new springs and go from there.

-

Thanks Clint That would be a baseline for the vehicle and then a recheck with the new stubs? Was there any issue with the belltech ones?

-

My 2000 Silverado has lowered front springs that have sagged to the point that it is just about sitting on the bump stops. I was looking at @cletus thread for his truck and it used lowered springs plus lowered spindles. My question is are there lowered spindles that are type approved or will I have to go through a toe test?