-

Posts

24,279 -

Joined

-

Last visited

-

Days Won

3

Content Type

Forums

Downloads

Events

Gallery

Everything posted by Bling

-

I imagine it would be like cutting or compressing springs. Not legal but hard to spot if done right so gets passed for that reason. Modifying the parts that hold the wheels on opens up a can of worms if an idiot does it with low quality parts for example. 2c

-

If done right I don't imagine so, a bit above my paygrade to confirm.

-

I used Nordlock washers too and plain washers + nordlock to caliper as it was aluminium. Cap screws for most things, 10.9 and 8.8, 12.9 were not suitable for cyclic loading so I just avoided them completely in the end. Wouldn't think a nut would be needed on back side of threaded hole. My rotors used nut + bolt, but where the bracket attached to the strut itself the holes were threaded and so just bolted through the holes as per factory.

-

Could be worth asking whoever is going to cert it. My process was a bit different as I popped to see him a couple of times to get parts documented before build and to make sure I was on the right track. When I dropped car off I had printed documents which had material info, source of parts and the likes. I also listed out everything I had modified on the car. This might not be a requirement at all, hence it could be worth a phone call. Was easy to write it all up though so I figured i'd do it to make certing a bit easier. I changed some of my plans as they would have meant changing certifier due to classing. So certainly worth letting them know all the mods before going too deep.

-

That looks pretty rotten. I'd cut it out and put some flat bar, epoxied to the structure in place of that rotten area. Then depending on motivation levels, chuck some fibreglass / boat repair kit at it to bring it back up level. Then redrill it and chuck some nice long rivets back in. Would maybe predrill the flatbar and chuck nails in the holes while doing repairs so you don't risk dislodging the flatbar after all finished. Epoxy should hold it ok though if underside of that area is clean. There will be cheaper / easier ways to sort if not wanting to invest much in it though.

-

Id be tempted to look at wall anchors used in the likes of gib. Lack of access behind makes it a pain. Rivnut won't have much grip I wouldn't think. If there is space for wall anchors they open up nicely behind so should be pretty solid. Might get away with just two instead of needing all three holes as some have pretty large anchors behind wall.

-

Could come down to setup. For a water trap to work the air needs to cool a bit so having at it compressor is a waste of time. If the compressor is working it's arse off too, that will be creating more heat which won't help. If you can have the trap a decent distance from the compressor it will give the air a chance to cool a little and could help it work better. Depends how you have it setup really. I'm sure local compressor suppliers will have traps available. When I got mine from Marquip they had all the bits available. Probably just reselling aliexpress bits, but still available.

-

Was Ken for a burger but just not able at moment. Mushroom burger sounds decent!

-

Caravan looks great, especially behind the VG. Can you not get a Supercat for the bike?

-

Yeah the government is blocking the resetting of land rover airbag lights. Take off the foil hat.

-

Sounds like a lot of effort to go through before you've actually asked dealers / auto sparkies if they can fix it. That should be step one, before wondering about certs and the likes.

-

He got offered 5k, countered with 50k or a internship, doubt he got it.

-

How long before we need a Leaf thread and get banned from OS?

-

All good, can probably pop past and try the bits that aren't small / removeable. It's no $15k scanning kit, so has it's limits but yeah hit me up later on and we can go from there.

-

When do you need it done by? I have a couple of scanners (Revopoint Mini and POP2), but I don't tend to lend shit out after being burnt too many times. I'm local to you but can't do anything for a couple of weeks I would say as recovering from surgery. Could bring your bits over to scan. Flick me a PM if that works.

-

Will check my stash when I get out of hospital, cheers.

-

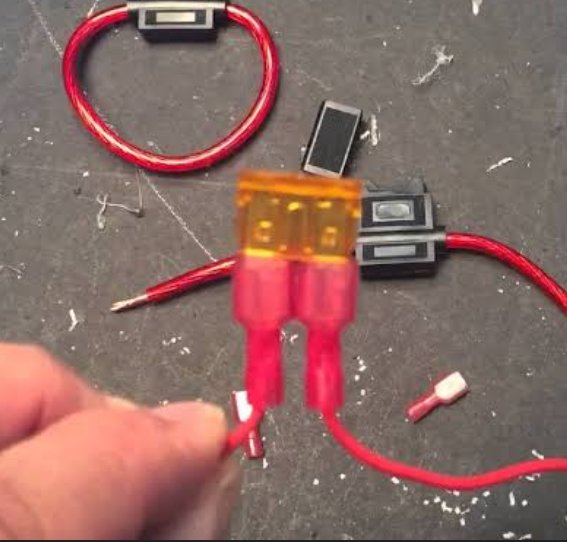

Thanks team. Odds of getting wet will be very very slim. Dry weather car and it will be tucked with fuse box. Example photo above. I have the ratcheting crimps which seem pretty solid. Have same setup in other car for years. But figured I'd see if anything inherently wrong with the setup before using it again. Was looking to use spare fuse box slots, but doubt id have the correct fittings to slot in. The vacuum setup on the carb will already blow your OCD socks off if you happen to pop the hood.

-

Power for amp and stereo. Any reason to get proper fuse holders over just insulated (with added heat shrink on each spade) spade fittings onto fuse? Fuse holders are relatively cheap (though I'd have to go Narva not Temu, same same I'm sure) but they all required connections to different wire sizes and I have the wire to do the whole lot the same gauge. Low requirement 10-15A(ea) not at car to confirm. So yeah anything wrong with that connection type? Both will be secured at battery so pretty well protected. So yeah $25 well spent or is this fine:

-

No can do Harry, plates pretty full. Ken one year though.

-

Try NZ Impers, on Facebook.

-

Measured from top of arch as far as I know. Won't be many arches that don't curve inward. This part of the PDF covers bolt on flares, but if if you just have unmodified body, then measure the same way and should be good. I'm sure Clint will confirm yeah / nah. https://www.lvvta.org.nz/documents/infosheets/LVVTA_Info_05-2020_Tyre_Track_Protrusion.pdf this one shows factory body better vs tyre tread, only shows front/back profile with top of arch used as reference https://vehicleinspection.nzta.govt.nz/virms/in-service-wof-and-cof/general/tyres,-wheels-and-hubs/tyres-and-wheels#tab2 Unless it was posted by someone you know isn't an idiot... then take with salt. Front guards for example tend to just bolt on, so I can't see how they would link that to being structural. That said, people will probably ruin guard rolling too, by taking the piss and they will have to bring in rules. Had to flare mine to get enough clearance through full suspension travel for my cert. Didn't even come up as a mention when I explained how I got the clearance. Double skin in rear of mine so fold it over doesn't really change much. Front couldn't do much as bolt on single skin so weak as fuck arch.

-

Keen for your timing brains. Thanks for offer on burger but I pretty time poor as well tonight. But keen for some sharns for a bit anyway. Edit: oh lol, well if it can't be looked at tonight that's all good if you happy to short term lend it while I work out how such things work.

-

Does anyone have a timing light / the knowledge to check my Rolla if I drag it along? I have no idea what I'm doing so haven't solved my dieseling problem. Will just hang out pre burger as poor lol.

-

Is it 7 usually? I can't remember.

-

Yeah one of those helmets would do the trick for sure. I just rolled 18V fan blowing all the goodies out of the car and outside the environment. Can't really justify such luxury when I only weld once a year on average.