-

Posts

22845 -

Joined

-

Last visited

-

Days Won

3

Everything posted by Bling

-

I had similar problems with my compressor, although its a big unit it had the most pathetic valve on the bottom that gummed up really fast. Replaced with elbow and 1/2" gas ball valve, ear muffs on job to drain that now. As for the coating, i'd be surprised if it did anything but fall to bits and clog your valve. Even when they do fuel tanks after acid dipping I think it's not THAT reliable. I just leave mine empty with valve open when not in use and hope for the best.

-

I paid just under a hundy for test with co2 fill. So in that ballpark, but more for the gas in your case.

-

Yeah +1 for 0.6mm wire. You can weld some pretty thick stuff with it in a pinch. But for panel work, it's perfect. I've even gone as far with 0.6mm wire as to repair a table for someone which had reo bar as legs. Sure it wasn't ideal, but it welded the 12mm bars together more than well enough. Obviously for that job thicker wire would be easier. But for panel work 0.6mm is the go for sure. Have used it for 0.5mm sheet, 2mm brackets, thicker box sections, no worries. 99% of my welding is on just shy of 1mm sheet.

-

We can agree to disagree. What length / spec springs do you have in the starlet? Project photos don't work now for me to look. But I assume you don't have keeper springs if you have the most suitable springs. I can't remember if FA ones are 150mm or 200mm (the normal ones MRP supply). How did you determine platform height if adjusting it is such a no no? Pretty sure you would have used the platform to provide some of the height setting for your car. The whole point of adjustable platform is that you can have the springs setup as needed, then move change the car height independently. Multiple ways to lower a car, none of which make the other obsolete. If you don't want to make use of the platform adjustment, you wouldn't buy suspension with it one would assume. To me the body adjustable platform is just another lever you can pull to get the required results.

-

Yeah you can set any suspension up wrong or right though. With either method. If you have a suitable main spring and keeper setup, I don't see the harm in moving that up and down to change height. Not an expert and no plans to be one. When you can't get off the shelf options for a platform though, you have to come up with your own solution. Sometimes buying a few pairs of springs, likely custom made, isn't suitable for the wallet.

-

I'm intrigued as to what you are driving with this setup. Is it legit balloon tyres or just a poor choice of wrong offset wheels?

-

Yeah cylinder size / type will depend on usage as well. I had my owner cylinder (6.8kg)tested in the last couple of years and filled with CO2 for ~$100 all up. No plans to start any rusty projects in the future so it will likely need another test at next fill. No rental to worry about makes it pretty cheaper motoring welding.

-

Nice and flat for orbital sander to whip it off. If going chemical make sure it won't react with the cladding which I assume is aluminum.

-

Why shouldn't you be adjusting the height by moving the whole body? Seems like the logical way to me. Spring perch is only useful to setting preload and the likes.

-

If matching existing the code will be pointless really, you should have started with that info lol. As for getting paint made, not terrible expensive no. Pay a bit more for them to fart around mixing the paint to match what you have though. They have to mix it, test it and dry it, change the mix a bit, rinse and repeat. So take them the fuel filler door and see what they say. I don't recall exact pricing, but it wasn't bad. I was just doing small areas so cheapest option for me was to get a tin of paint made, might have been 1L. Then have the put it in some spray cans. Rather than buying the paint in colour matched spray cans. Same result but they said cheaper (at my local anyway) to do it that way. Not a painter, but you'll never get it bang on, so will need to blend it into the other panels if wanting a good job. I didn't care about my car so just painted it without that worry. I still have paint left over for future repairs too. So best value is probably getting more paint made than you need. Then you have the option to get more put into spray cans if going that way. If using a proper sprayer obviously don't have to worry about that step. Oh and my paint was just basic bitch stuff, single stage so not sure on 2k base + clear pricing, but wouldn't surprise me if still reasonable.

-

Maybe try that road first then. They will know what is and isn't in their system. When I got paint made they could use the paint code or match off my car. No point getting it made off the code unless doing a full respray, due to years of fading. No idea what you need it for so that's all I can add really.

-

Any decent automotive paint shop can match off something you have, fuel door etc. Has your local paint shop said they can't knock something up for that colour?

-

I always used sheet that was treated in some form (zinc) as my repairs took months / years. Was mostly new gas fire panels because free. Could sit around in the garage and not deteriorate, unlike my untreated stuff. Can't go too far wrong really, just stay away from galv stuff and remove coatings where you are welding.

-

It's empty at the moment so that won't be helping things, probably less than half a tank of fuel. So half of the problem will probably be gone by the time I add a spare wheel, jack etc, fill the fuel tank (haven't dared yet as no fuel close to home). I do have a sub and was considering putting a floor in it to help secure that. With a lid to get to spare wheel. I'm not too worried about the adding of weight from a performance point of view, because it doesn't have performance. I need to actually source a spare wheel as I don't have one. Other than the Hoshino wheels on it now. I'll do my homework on the droop rules / regs in the meantime. But yeah adding sounds I have sitting here would help the situation, if it came to it.

-

https://www.autorepairsdirect.com.au/blog/differences-between-epoxy-primer-and-self-etch-primer-for-bare-metal Pretty sure this threads consensus is epoxy primer the world.

-

Would probably need an example. But often things bubbling up, started corroding on the other side of the panel. If it's 100% just on the front side of a panel, then what i've done is wirewheel, then metal prep with an acid product to get in the pits, then clean, clean, clean, then epoxy prime.

-

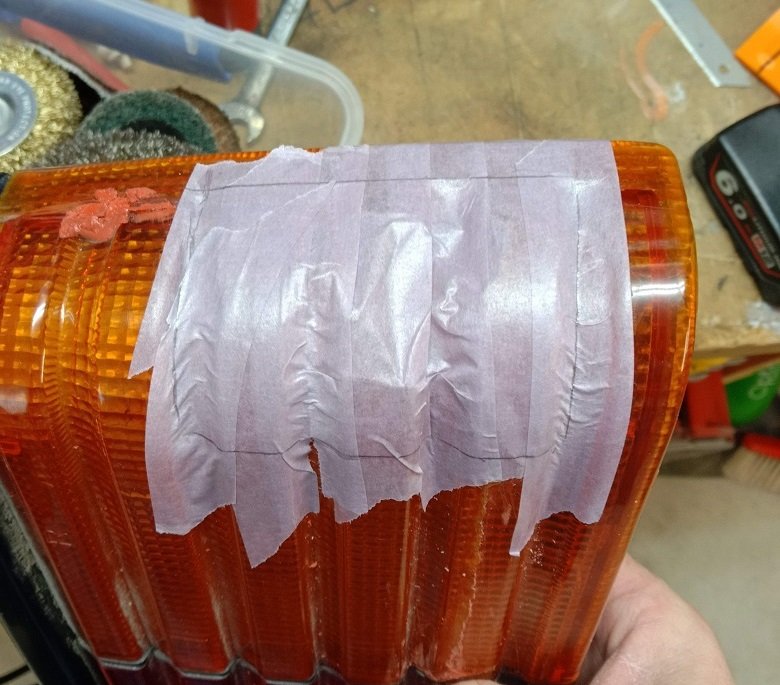

Shit a brick, over a year since last update... So believe it or not, this thing is still progressing. I'll try remember what i've done while I write this update. I have taken it to my local garage to get some jobs done. Jobs I can mostly do, but I want it in for cert this year not next year, so gotta be done. Had the carb checked over with some work done to get things running a bit nicer. It starts easily now and runs fine, just needs a bit more work when coming to a stop. I'll probably fiddle with the idle a bit and see if that sorts the stalling. If not i'll get garage to take another look. I got some longer shocks for the front coilovers as I was sitting a bit low (impossibru). Wanting to keep the fenders factory so that coupled with pretty square tyres on much wider than factory wheels, means they are close to rubbing it too low. So the shock bodies are 50mm longer, which gives me the option to keep it as low as it is now and also lift it 50mm while still having enough of the shock captive in the sleeve on the hub. I also installed some keeper springs up front as I only had 30mm of droop from memory, so now I can have 30mm up to quite a lot. So i'll set it at 40mm potentially for now. But may change that to 50mm if it isn't going change my bump steer enough to cause issue, I have no idea on that stuff. Rear suspension is unchanged, but I still have some work to do in that area as I don't think I have enough droop there. So may need to look into the 1/3 droop rule. There is only so much weight in the rear once you take the diff and wheels out of the equation. And the springs I have were developed specifically for AE86 and are progressive 4.5kg. Worst case would be having Cobra make me some springs of lower rate, but that is last resort as they will not compare to the springs I have ride wise. Can only fill the fuel tank so much, so i'm a bit stuck as to how to add some more weight without it being super obvious that's what i've done. Anyone with ideas around this problem please let me know. Interior is complete now, all belts installed, plastic trims and the likes. Have swapped out the dash cluster as the temperature gauge wasn't working. Asked in spam about diagnosing things and found the sender on the block is working fine, the wiring was fine, which only left the cluster. So i've swapped in another one, thanks Goat for including all of the spares with the car! So I now have a fancy as fuck analog clock and no tacho, but a working temperature gauge, so i'm happy with that for now. Don't have the money to pay someone to fix the other one at the moment, but i'm sure it's something I can swap back later. So now I have a working gauge I could see that the engine seemed to be staying cool enough. I'm not 100% convinced the thermostat is working correctly. So I may swap that out when I have a bit more motivation, just to be sure. So that's where it is for now, fine tuning the running of it, then i'll book cert and alignment. Still haven't set the final height yet, but that will happen. Excuse the wall of text, there will be lots of missed, but no point making the wall longer, so here are some pics. Fred for discussion etc Oh yeah forgot I 3D printed a few bits for the car, very rough and ready, but I have a better 3D scanner now so plan to make some better parts when time allows. Longer shock body comparison Printed bases for my mirrors, only have one good one with car so 3d scanned it and mirrored for other side. Came out ok, but will improve on it when I have time. Had a taillight to fix as well. Replacement lights are just not a thing here. I spent a very long time watching Japan auctions but any I found went for (to me) silly money. Think the last pair was north of $500. So I printed my own repair as I don't care what it looks like, so long as it's functional. Before: Printed a test section out of plain orange filament I already had. This was after scanning the taillight on my other Corolla. I could have just as easily scanned the passenger taillight of this car which isn't damaged and mirrored it. But since I had a drivers side to scan, I did that instead. Didn't take too much work to turn it from a scan into a printable object. Print new piece out of transparent orange filament. Trimmed the original print down till it just covered the damage, before printing the final version below. Sitting in place Glued in place and painted over the whole thing a few time with transparent modelling paint. Got it closer to original shade and tinted all the clear glue I had used to fill the gaps. It's no piece of art, but it sure beats the before version.

- 23 replies

-

- 23

-

-

I used to do batch work, so would cut a bunch of rust out, then spend the time making all the panels to replace it. Then paint as above. Saved getting all the tools out each time I was doing the next repair. I don't have the space to spray so I used to just make up a mixing pot of epoxy primer and brush it over all the repairs. Bad memory meant I had a list of repair locations written down , so whenever I had some primer mixed up i'd give them all their next coat. Areas inside often got 3-4 coats as if I mixed up too much primer.

-

Used to use a cheap aliexpress one at work, seemed reliable and accurate enough. Will be the same as above, there will be a million of the same thing on ali.

-

I just have screw on ones on the project as it's what I had in the garage. If the pressure in the system is enough to blow those off I probably have bigger problems. That's my theory anyway. The other car still has all of these on it:

-

Tomble's 1983 Starion GSR-X fumbling / hand-holding / discussion

Bling replied to tomble's topic in Project Discussion

Ah right, carry on then lol. Those rear setups look good. Keep us posted anyway. -

Tomble's 1983 Mitsubishi Starion GSR-X fumbling

Bling replied to tomble's topic in Projects and Build Ups

NaN Admin delete please, posted in wrong fred. -

Just don't forget to count the engine on hours, that is the main thing to look for remember. Check the gloveboxes for Barries 3B1 book with all that data recorded.

-

Yeah obviously engine hours matter. I regret even suggesting now that higher mileage equals higher wear. Thus why lower mileage cars are worth more as a rule. Which was not considered in the post I quoted. It's being nit picked to death. As you were chaps.