-

Posts

11,673 -

Joined

-

Last visited

-

Days Won

2

Content Type

Forums

Downloads

Events

Gallery

Everything posted by flyingbrick

-

Waikato tiki tour Scooter/small motor bike

flyingbrick replied to 64valiant's topic in Upper North Island Region

Such a good day/night. Next time i think ill wear a camelpack to help keep fluids up. @Raizer i kicked the new scoot over this morning to test your coil wiring. I had bare feet and wet hands- got a zap through the handlebars LOL Also..super good to meet a bunch of you guys/get to know you all in person. @64vauxhalls wifes bike was such a dream. Keen to see what went wrong in the rear hub. I bet these magazine guys got some good snaps! Felt like every time i went past one of em i was tucked behind the bars trying to be aerodynamic. Must hsve been so lol for any of the public. Oh and thanks beth greg for letting me ride the bikes! Huge thanks to beth for driving the support car and massssive thanks to @nickrock for the leather jacket. I wore it for 12 hours yesterday - it fits me well, is comfortable and looks badass- you are all truely GC'S- 148 replies

-

- 5

-

-

I stuck a disk of metal to the snout so that i had a solid guide to sand down to. This made things MUCH easier. Nearly ready for final assembly, waxing and mold making. SO MUCH SANDING but ill be forever upset if this comes out all wavy. I bought a good new oil pump. This is exactly the model i wanted (high pressure standard flow) and the price was great so couldnt not get it. My ali express fiberglass turned up for the mold too.

- 137 replies

-

- 11

-

-

Waikato tiki tour Scooter/small motor bike

flyingbrick replied to 64valiant's topic in Upper North Island Region

depends if i drink or not but i may end up sleeping in tray of my ute. Its not that large so probably have to have canopy door open, tray down and feet poking out.- 148 replies

-

Waikato tiki tour Scooter/small motor bike

flyingbrick replied to 64valiant's topic in Upper North Island Region

I really hope i end up with something to ride. @64vauxhall and #mowgrass been trying their best but who knows.- 148 replies

-

Waikato tiki tour Scooter/small motor bike

flyingbrick replied to 64valiant's topic in Upper North Island Region

Mine too. Holy fuck so much excite.- 148 replies

-

Waikato tiki tour Scooter/small motor bike

flyingbrick replied to 64valiant's topic in Upper North Island Region

Ill pay you for it.- 148 replies

-

- 1

-

-

Require use of parts washer - Waikato/Cambridge

flyingbrick replied to bonkas's topic in Upper North Island Region

Petrol is good. Chuck ya small stuff into a bucket, let it soak and give it a shake around every now and then. The motorbike place beside midnight upholstery in hamilton (t straight) has a vapour blaster. Dunno what they would charge to clean em up but worth a try -

Wheelies must be TERRIFYING

-

I also drew up and laser cut some mount adaptors. I coppied the basic idea from the few ausie hq- LS mounts available (but i aint spending nearly 300$). Mine all slotted together and were good enough for welding without a jig of any kind too.

- 137 replies

-

- 15

-

-

I love how excited oldschool gets when our cars dont break down.

-

-

Waikato tiki tour Scooter/small motor bike

flyingbrick replied to 64valiant's topic in Upper North Island Region

is that last pic round in Te Pahu?>- 148 replies

-

Worst. Porno. Ever.

-

Well done. Drag racing the thing sounds scary... please get video.

-

They make some really cool shit!

-

Stupid comment i think but will say it anyway.. Isnt the sender supposed to turn a bit more in its seat and click over those bulges? Sorry if thats the dumbest thing ever suggested.

-

Do you think it could have been flex at the feont of the chassis that did it? Looks super flimsy there (its the only bit you havent reinforced)

-

Pussy.

-

Come up for the waikato scooter ride

-

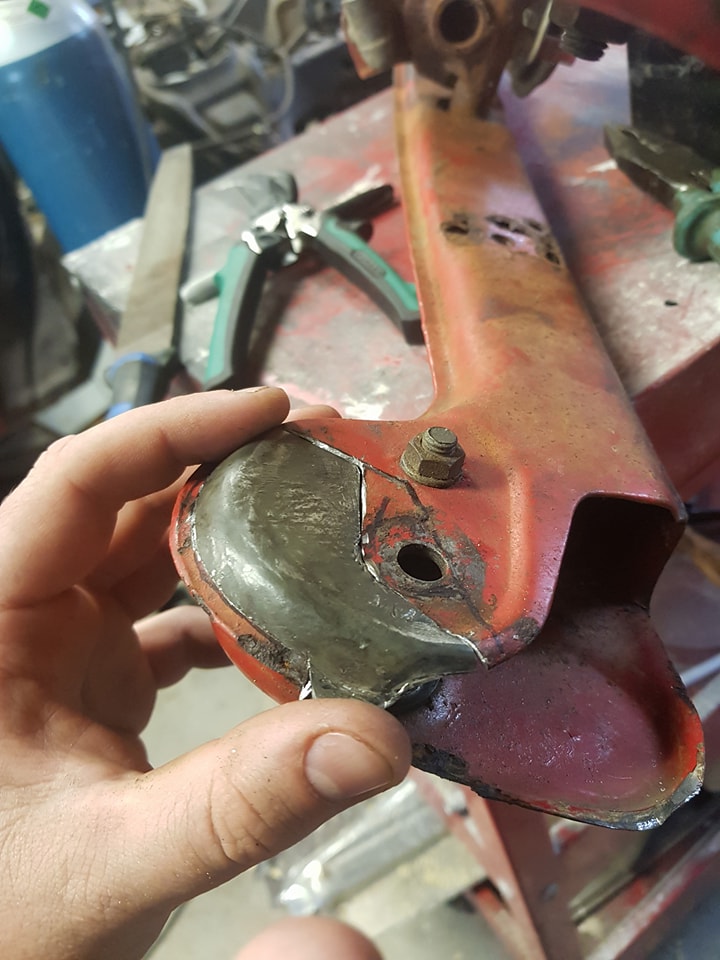

I spent a few hours out on this today. First I made that first piece fit. I cut out this So that I could fit this. new steel wasn't quite large enough to replace all the shit (bit by my thumb on the seam) but will deal with that later. I zapped that in and moved to the other side, I cut this out, And then realized that now was a good time to straighten the bend at the bottom. I don't have many good pics but the outside face had been in a pretty good impact and was concave rather than flat and this impact had tweaked the whole end in. (this should be parallel to the end and the seam straight) So both sides (now not attached to one another) were straightened and everything was measured over and over using bits of wood and verniers (to check overall widths) And that's as far as I've managed to get.

-

you discovered top speed yet?

-

you need dirt tires so that you can rip up the local parks

-

I actually cannot believe you did this and got it working.. must be soooo terrifying!

-

If it was a normal bottle opener without c&b would you like one?