-

Posts

3,390 -

Joined

-

Last visited

-

Days Won

2

Everything posted by kpr

-

primary's are 38.1mm tube. so 35mm id. out of the port its 32mm and actually tapers down to 31mm before the cone out to 35mm. sounds small, but have made 160kw on same sizes. They are actually going to be 4-2-1 . once get the 4-2 section merged together. will design a flange that will go just after the merge. Then can test a bunch of different length 2-1 sections. Im kinda going against proper science and trying a few things at once. Ideally i should test the high port head with the starlet exhaust side. but that wont fit the trueno. and the starlet ecu wont run the e -throttles. Have tested couple of very different merge collectors on my big headers, with zero change in power. How small they merge down to and whats directly after, can make a big difference though. especially in the bottom end.

-

Old bottom end out of the starlet will be going in this. which is a normal 4age, with toda pistons, bc rods, toda pump gears. I was revving it to 10k, plan was to drop it back to 9500 for the easy life. It will have vvti and probably some cams i have hanging around to start with. Head will be stock valve. If works good i might modify the big valve head on kp to high port. Big valve conversion is pretty expensive, so this is kinda the test run. The head Ive modified to high port was an accident damaged head, has been welded and repaired. no big loss if its a fail.

-

Started making some pipes Half of the internet told me i need to test stepped header because will sound like a f1 car. So i made some cones instead of steps

- 71 replies

-

- 20

-

-

-

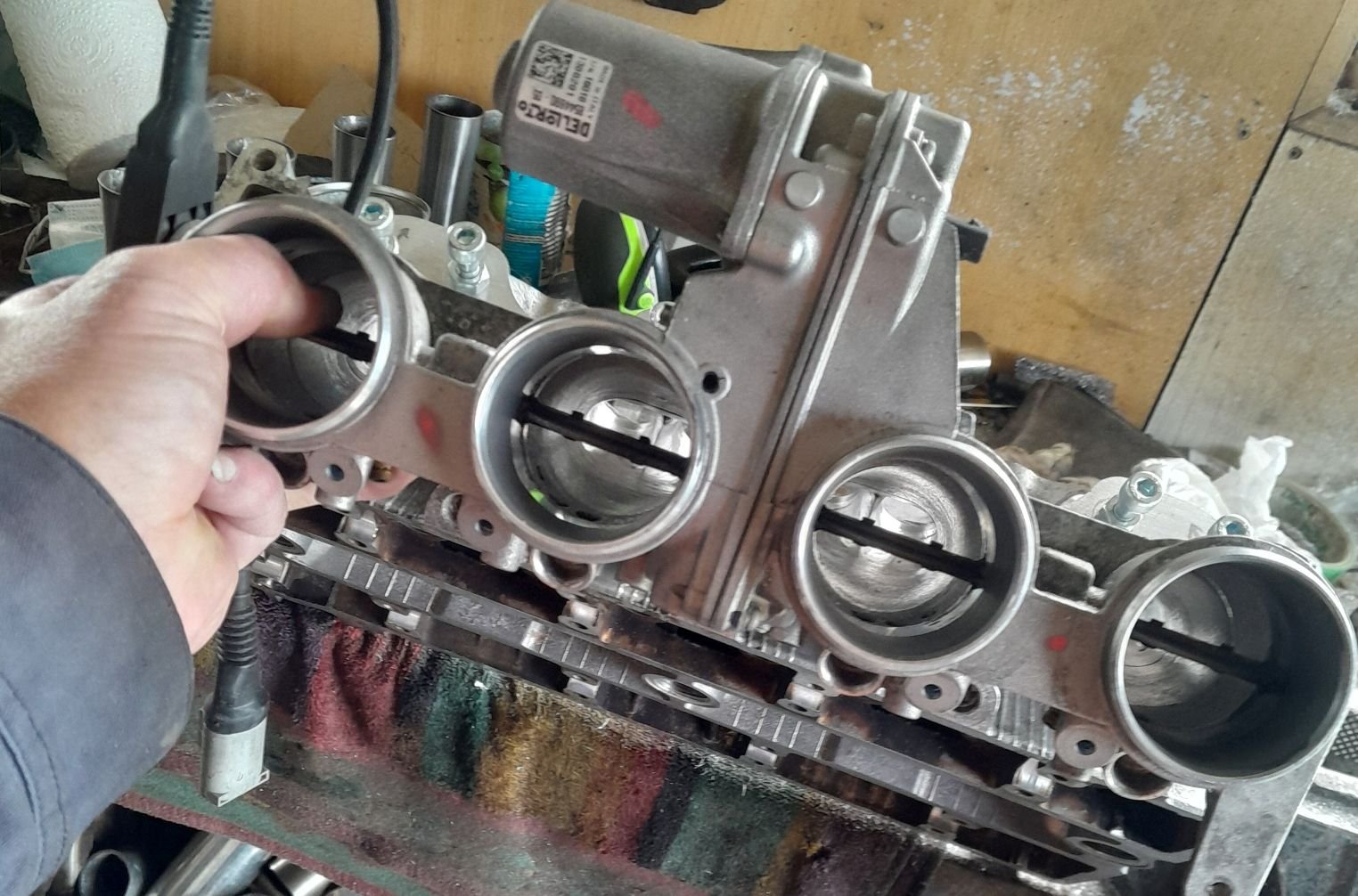

Got the intake manifold welded together and finished. Doing some rough maths, have halved the turn in the port. from a 67 deg turn to 33 ish. Along with making whats left of it a bigger radius gave the outlet of the throttles a bit of a zing also, as outlet isn't round and kind reduces in diameter fast

- 71 replies

-

- 42

-

-

-

-

That wont handle romans right foot.

-

-

someone release the weight off this mans shoulders

-

Yes and a speed spenduino ecu only because its on the run in tune, it will go to 12,300rpm no problems

-

Intake ports almost finished can see how much the ports have moved compared to the picture i stole off the internet below / update

- 71 replies

-

- 27

-

-

-

Yeah, I tired a 3au and a 4k but they were too fast for my skill level. so thought would start at toyota's lowest power offering and work my way back up

-

Other than the regular updates ; This has obviously been sitting for 10 years or so. Since i cant choose what other engine to put in it. its getting another 4age. Plan its to make it run and drive nice. Because I already have a rattly kp that will always be faster I could just turbo a stock engine and it would do those things and also be faster. but done that and would be boring and too easy. So the only logical thing was to get a smallport head, and cut the inlet ports off in my lathe mill Insert stuff i dont want to show yet lots more butchery, welding and stuff I basically had to cut way down into the port and add a bunch of material and cut a bunch out in other places. So it actually makes the short turn radius better. I'd looked into doing it many times before, but seemed pointless unless went full ham. originally i was going to weld the pipes below directly to the head. but they ended up so high on the head, that it wasn't going to be possible. so welded a flange to the head instead, for a bolt on manifold. More work, but better for many reasons High port vs stock port Is a bit more port work to go, but the basic shape is roughed out. Angle looks pretty aggressive when in the car. Will be running 48mm bike e throttles, same as what @Roman ran on the 1nz. the outer runners/ports are tweaked in a touch to line up with the outside throttles, otherwise line up good.

- 71 replies

-

- 35

-

-

-

-

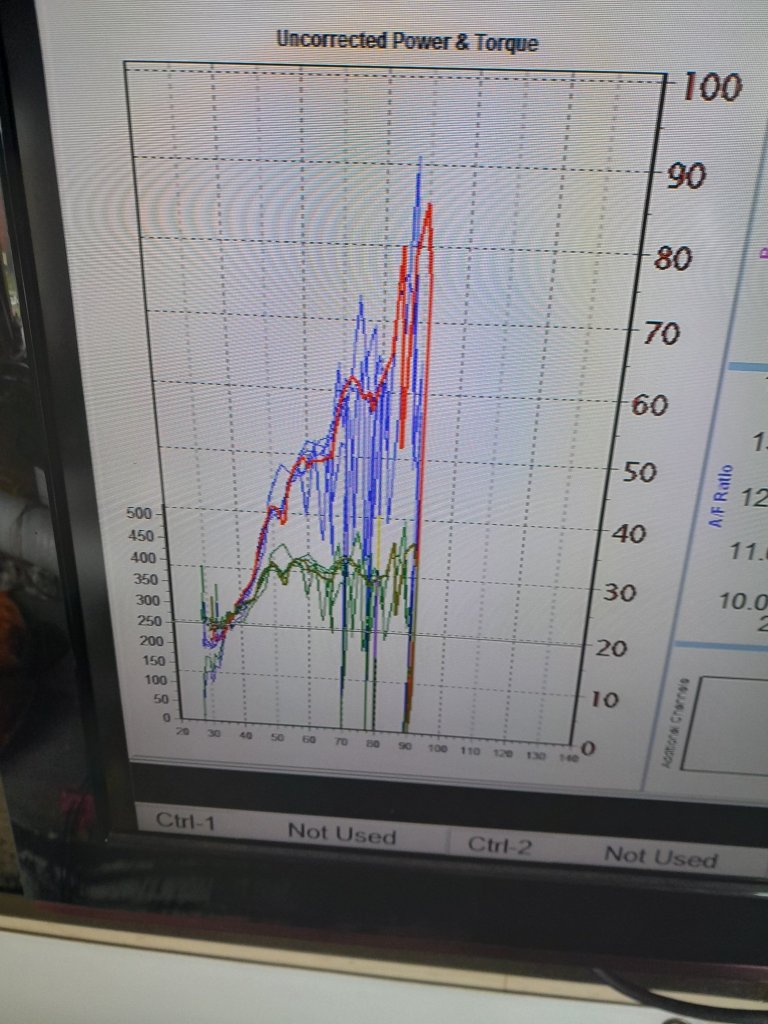

https://drive.google.com/file/d/1o7qb07Phu7HxqyE9XOgbre_5yKalDwV7 well that doesn't embed - video of said car doing dyno run ^

-

Gates is garbage

-

Pretty sure they have an oil cooler on it. this one had some kind of aftermarket sump also. Their other car runs a stock engine, but doesn't look like i saved any logs off that one. Increasing the relief pressure doesn't seem like it would make it hold pressure longer.

- 417 replies

-

- 1

-

-

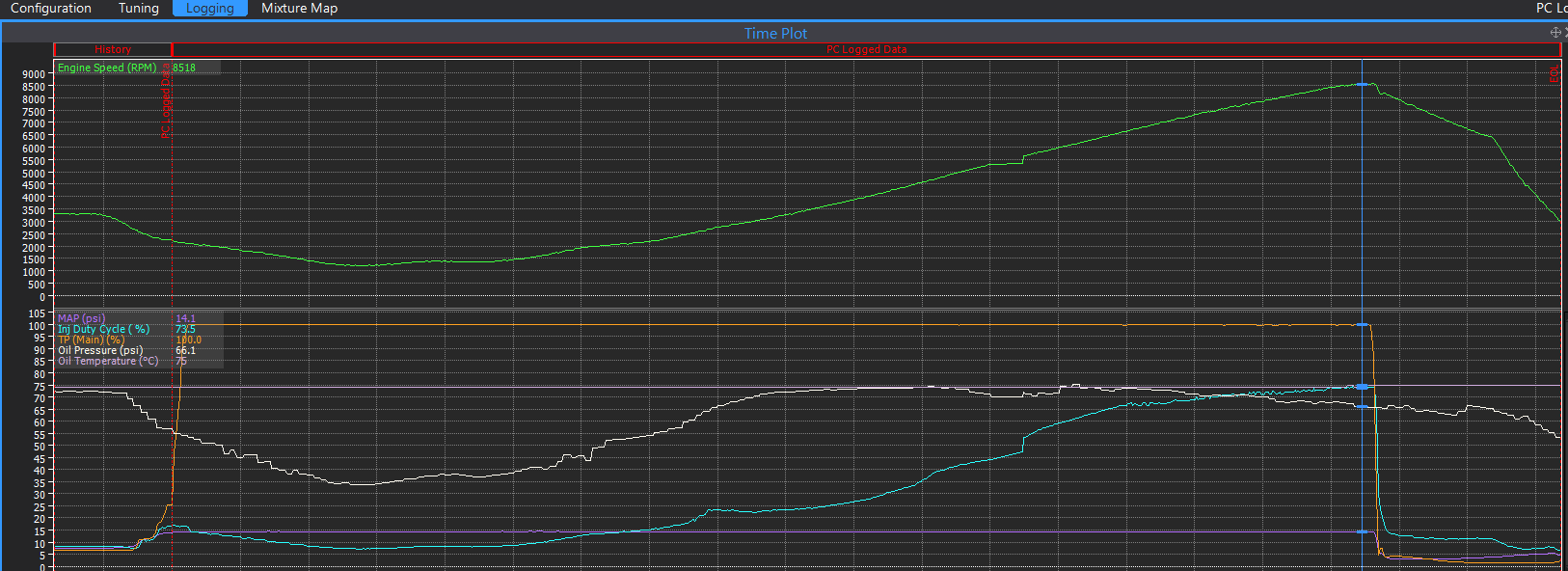

peaks at 74psi, drops to 66psi at 8500rpm. This is off one with aftermarket cams, unsure if stock oil pump. is the only one i can find a log off i would expect be lower over all once got some more oil temp in it. is only 75c in this log. Is only 1psi in it between 8000 and 8500rpm, so isn't falling off a cliff

- 417 replies

-

- 1

-

-

How much does the oil pressure drop in the top end? have noticed the ones ive tuned the drop a little up top, but nothing to significant. usually limit them to low 8000rpm and seem to survive a 6 hour lemons race. may have some link logs have saved off dyno runs, can look if your interested

- 417 replies

-

Forgot to say; for reference, without the cam belt on you should be able to move the vvti pulley by hand very easily. first few times through its travel will push the oil out. but if binds up before coming to a hard stop, loosen the bolts off and slowly tighten them up a bit at a time, while moving the pulley back and forward. should move 30 deg as you say (60 crank degrees)

-

have a tune here off a running vvti 2jz, vvti offset 172 and trigger offset 200. I would be double checking the cam timing isn't a tooth out. when setting vvti offset, try set it a number or 2 higher than what its reporting in the cam angle test. as it can walk a bit. once you get it working log the vvti target vs the vvti position. Put zero in the vvti target map. if the position is hanging higher than the target when target is zero, you can wind the offset back. but keep it reading a touch above zero. as can get unhappy if the cam angle trys to go below zero

-

18th New Year Jap Oldschool Meet - 19 Jan 2025 Auckland

kpr replied to AE25's topic in Upper North Island Region

Actual shitcunt -

There are a couple ways to do it. Jz engines run a missing tooth crank trigger wheel and 3 tooth wheel on the cam with vvti. this works long as the swing of the vvti doesnt go through the missing gap on crank trigger wheel. so the 2 sensors do both the injection/igntion etc and vvti. Oher stuff like honda k series run a trigger wheel on crank and a one the non vvti exhaust cam. which does the injection/igntion. then they have another sensor on the vvti inlet cam, for the vvti cam position. so is 3 sensors i run a 3 sensor setup on mine