-

Posts

7,218 -

Joined

-

Last visited

-

Days Won

39

Everything posted by Roman

-

Dont worry, it will be full send at the drags. At a track day there's not quite so much benefit from revving it right out. But at the drags, its mandatory. I've got a few extra tricks up my sleeve this time, but it'll mostly be the weather gods I need to pray to!

-

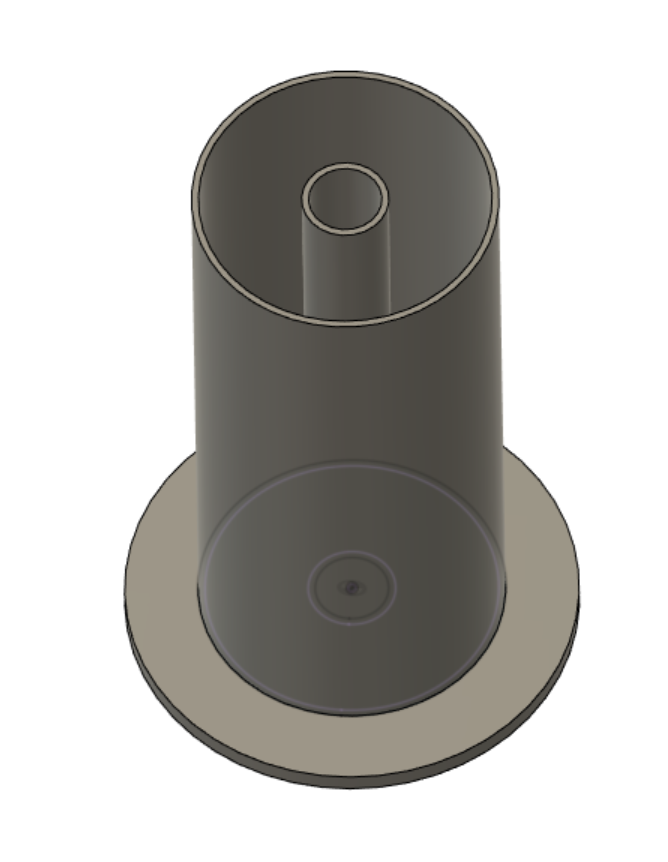

It's printed thin so that I can just break the mould off the outside. (and inside, hopefully...) Now have to wait 48 hours to play the "will the damn thing actually come out" roulette. By which stage, I'll have probably thrown these in the bin and the ones I ordered will have turned up haha. Bloody good fun making a mess though.

-

Ahhh crap was that the wrong pic? Buttplug_with_hole_for_beetles_to_crawl_into.jpg

-

Hah! My partner has a mini, and she's been wanting to put a more modern motor in it. I've told her 1NZ is a good idea and thats why I'm hoarding parts. Nice to know it looks to be actually doable.

-

On the front, I am using Ohlin coilovers which have an inverted strut, which is some sort of wizard magic thing that I'm definitely not going to try open haha. Not an insert. I'm not sure if this means the bump stop is actually internal down in the guts of it? I dont think there's a bump stop on them otherwise, anyway. The front is not a problem. On the rear, the spring is separate from the shock. So the bump stop just slides over the shock body. So I can pull the shock in and out really easily. So it's not a drama to experiment with it a bit.

-

Yeah Maybe @cletus idea of a solid spacer with a shorter bump stop is a better plan than what I'm thinking. This way can have a cone shape or whatever be more effective. I'm trying Shore A 60 simply because that's what I bought a while back to fill my engine mounts. Might be a little on the soft side for a bump stop. Also it might be a disaster and impossible to get out of the mould. haha. The ones I've ordered are this sort of shape, 85mm long uncompressed. So probably compress down to smaller than I'd like.

-

I think it will be okay. The bottom casing is quite shallow to the crank, then one half of it falls away to a fairly steep oil pan with some baffle type things in it. So at least half of the oil falls directly into that, rather than having to go down the slope. The main oiling issue is likely when a rod punts my oil filter housing off the block I've ground the guard completely flush so that there's nothing sharp for the tyre to catch on. But still it just wanted to sit the body on the tyre. Just further down now. I'm not sure what sort of antics they were allowing for with this HKS suspension but it's pretty crazy how low it can go haha. To get the car to sit on the bump stops while having tyre clearance, has needed this many bump stops random bump stops buts that I found in the shed: Which is about 90mm with a little extra allowance for further compression. So I found on trademe some 85mm bump stops for 4x4 so hopefully they're reasonably stiff. I'm also going to have a go at casting some bump stops from polyurethane with a 3d printed mould. As I figure it might just be fun to do, then makes it easy to try some variations later on if it works well. So I'm just printing a very thin walled tube. So then I'll use lots of mould release wax on it, then after pouring hopefully I'll be able to just break it off.

-

On the toyota running speeduino. With the factory loom the earth for the cam and crank triggers tied together and ran to the ecu as a single wire. The only way to get vvti / cam angle sensor to read correctly was running a new wire all the way from crank trigger to the ecu. As I think the filter for interference or whatever on the speeduino wasnt great.

-

Super fizz mode about drags coming up! But I've also making plans to get to another trackday on the slicks. So I've taken the rear springs out to check for clearance. Looks sweet with no springs haha. I've chopped a bunch of the folded over part of the inside lip out of the rear guard. It should all fit inside the standard guard shape without rolling them out, or flares, or other stuff that would detract from the Je ne sais quoi of this magnificent beast. On the front, when sitting on bumpstops its got good clearance all round, thanks to the camber bolts. Sweet! (Front slicks not fitted in this pic obviously) So the only other task needed before a trackday (apart from avoiding blowing up the motor) is fit a bigger radiator.

-

That colour is amazing! Going to look awesome

-

I know someone that got Toyota VVTI working with a Speeduino. It could be that the PID settings are a bit whack? Not sure if you've seen this video before, but it's my go-to when I forget (often) how PID works! Brilliant vid.

-

Haha, that difference in dyno plots is wild! Cant wait to see how this goes

-

Holy shit! hahaha. Unreal

-

Yeah autotune can work great if it's got good filters for steady state. But usually doesnt exclude enough stuff. Or sometimes makes massive waves in the fuel table as it fluctuates half way between two cells, and keeps making one richer and one leaner to try get target.

-

Look forward to seeing some progress on it.

-

Sorry to hear things have gone so badly. As much as I do enjoy reading your well documented and reasonably light hearted masochism. Every man has his limits. I felt like I sold my SW20 under similar levels of being worn down by problems. Sucks. When this sells, what's next priority on your list of projects?

-

Ideally with an NA motor you want to stay around the 12.8:1 (richest) to 13.2 (leanest) sort of range for best power. Anything where you're dipping into 11s and you'll be losing power or possibly even misfiring EDIT: Sorry not sure why it included an off topic pic. haha

-

I'm glad this project has come along this far! Awesome to see wof/reg on it. What are your thoughts about the head swap, does it feel much different to a standard engine?

-

Dyno Day 19th November, 2wd rolling road

Roman replied to R3spct's topic in Upper North Island Region

@R3spct some footage you can pass on to the guys -

13s would be a piece of cake! Even with a soggy launch can just brute force it with some mid track onwards power haha. If you're doing a 3.6 0-100 then you'd be well into 11s or 12s at the drags already, surely. Bring it to this coming OS drags! You've got 3 weeks to practice And you can get heaps of runs in without any pressure etc. Dont worry about going slower than expected, honestly I'd be scared just to hop on that bike. The first time you go, you'll wonder why you didnt sooner. So much fun.

-

Gareth (dyno owner) was kind enough to give me the raw data from the dyno, so I could load it into the dyno software to have a look. So I've exported one of the runs to CSV file then made some corrections. So I've applied a correction factor to bring the horsepower level down to where it's realistically at now (max 150ish) Then because engine RPM is entered by eyeball by multiplying roller speed by indicated engine rpm. I've fixed this so it shows the real engine rpm, accurately scaled from logs from my ECU of that run. So this is encouraging, as the max power figure is actually at a higher rpm than expected. Pretty flat power from 8000-8500. (Previously highest hp at 7700) So could possibly be a bit higher than 150whp now! Cool. Previously it dropped off a lot more sharply from 8000 onwards. Peak torque now showing at around 6300rpm which is also encouraging. (Previously 5500) Also there might be some minor improvements with some slight tweaks to fuel or ignition timing, when I can get back to the hub dyno for a few quick tests. Fizzing to see if there are some quicker times in it yet! Dont worry @RUNAMUCK based on this there's absolutely zero justification for dropping the rev limit - if anything it should be higher. haha

-

Thanks @R3spct it was a really fun day, and like you or one of the other guys said. It makes me miss the monthly torque performance dyno days that they used to have. Fun to get some people together and have a yarn. Yeah I'm not too worried about the numbers, dyno is a comparative tool used to find improvements. But it's also hard to say you're happy with how dyno went, without mentioning numbers haha. I'm looking forward to getting to the drags again and seeing how it goes now. I've got some footage of the other cars that ran on the day, I'm just waiting for youtube to finish processing the videos then I'll send you some links.

-

No way man, with that Ramflo I'll actually be making 200hp at the wheels and will blow my rods to smithereens!

-

Plot said 199hp at the wheels. Apparently 40% more torque as well... Definitely doesnt feel 40% faster and its certainly not doing that with like 3% more fuel haha. Virtual dyno has had a few runs in the 150ish range. But im hopefully back to the original dyno this coming week, all going to plan. For a proper back to back comparison.

-

Fun day at a dyno day today, organized by @R3spct - thanks for organizing! Lots of fun. I wont post the numbers up as I dont believe them, (a lot higher than expected) But the shape of the graph looks good. Peak torque to 6000rpm! Sweet. One issue was that looking in the logs afterwards, and you can see it on the runs. The operator wasnt able to push the pedal fully 100% down. So the dyno runs were done at around 96% throttle. However, this is my fault not the operators. As I've noticed this myself, unless I'm absolutely mashing the pedal into the carpet I'm not getting 100% throttle. So thats my own fault. But what I can do is make it so if you are at 95% on the pedal, then this makes the motor go 100% throttle on the engine. Easy fix. The big peaks and troughs from the dyno session with the standard exhaust look to be gone. So big thanks again to @kpr for making me an awesome manifold. I think it's somewhere around the 150-155whp mark now. It sounds cool, was fun to be able to see/hear it from outside the car for a change. Also I need to attach my trumpets properly, you can see that because the throttle plates were slightly tipped down, from not being at quite full throttle. It was pulling the lower edge of the trumpet up. from lots of airflow from that angle. Usually have a cable tie wrapped around the pairs. Will fix them on properly next time.