-

Posts

5,063 -

Joined

-

Last visited

-

Days Won

13

Content Type

Forums

Downloads

Events

Gallery

Everything posted by Goat

-

Shit this is cool

-

Yeah, these go in from the side. So just need to stop left and right movement. I'll press the web off tonight and have a looksie. What flavor loctite should I use?

-

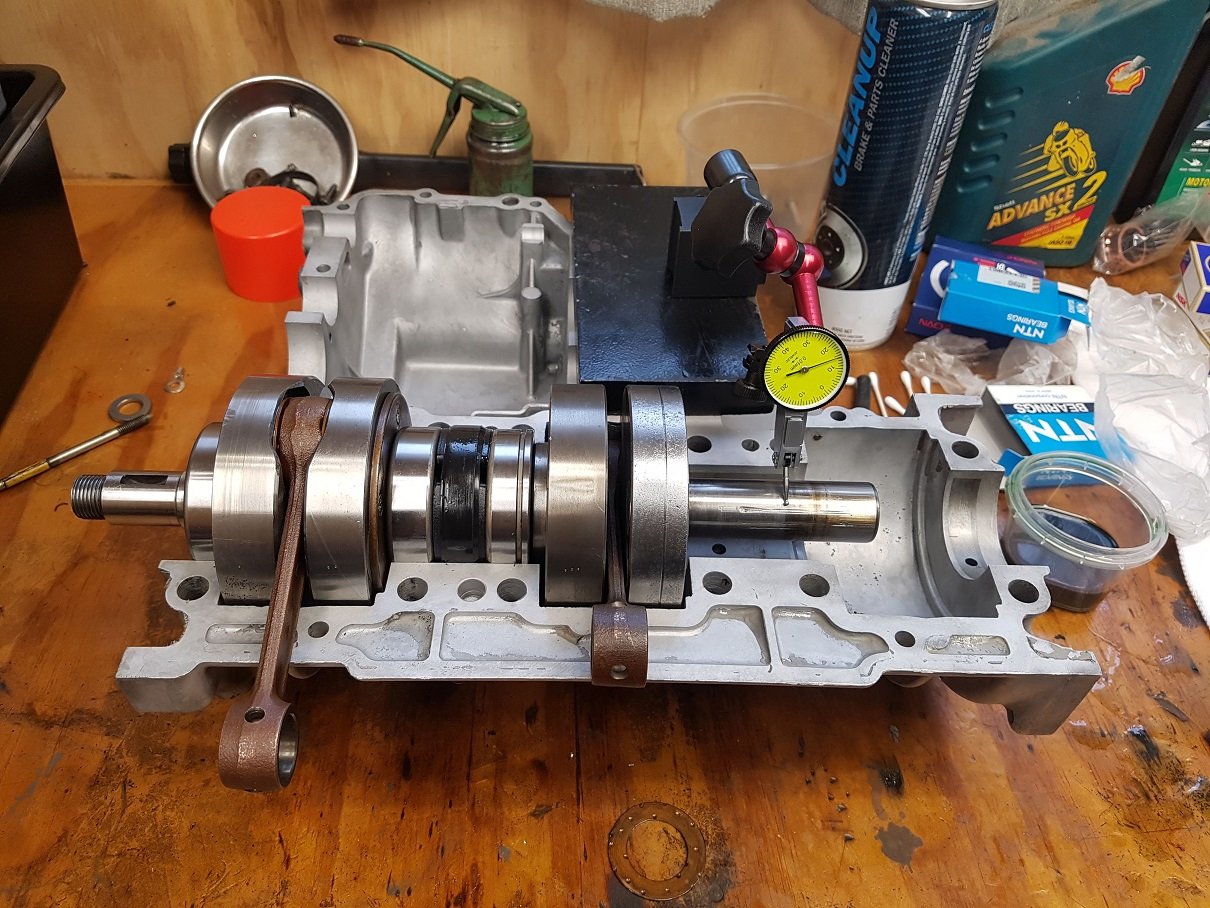

Finally the stars aligned and i have all the bits to assemble this crank! So I got stuck in on saturday. The 2nd hand crank i got turned up. So pressed that apart and soaked it in evaporust: The sections i needed for my original crank were in good condition! Excellent. I then prepared a clean starting point: And started pressing together Checking clearances (spot on): ] Then using my 3d truing stand (pic sans bearings): I trued up to 0.02mm. Its all going well! All was going good. Then drama hit. I was fitting the replacement web, and i couldnt get it to true. It was too close at the opposite side to the crank pin, you rectify this by driving a aluminium wedge in between. So no dramas there. But somehow, between the wedge driving and the truing blows, both of the poured in counterweights came loose. No biggie, i'll use the other replacement crank web. Shortly after, the same happened with this one. So now i'm not sure what to do, can i juat locktite them in? Do they need to be melted out and repoured? I don't think its just lead, its some special alloy that is super heavy. Dumb! Nothing ever turns out like Alan Millyard. Not sure where to go now.

-

Yeah man, I can do that for you. PM me

- 1 reply

-

- 1

-

-

King Country Crusade 17th 18th 19th November 2023

Goat replied to alfalfa's topic in Lower North Island Region

Oh man, This looks super rad. -

Tomble's 1983 Starion GSR-X fumbling / hand-holding / discussion

Goat replied to tomble's topic in Project Discussion

I've said it before and I'll say it again. Love your work. An inspiration to get out and do stuff. Color is rad! This thing is going to be so choice when it's done! -

None of your updates are punishing. They're all super enjoyable to read. Love what you do. Don't change. hah.

-

That doesnt look too bad at all, I'd just hone the cylinder and biff some new rings at it. If you can get a new piston for not much more, than do that too. I've seen alot worse running fine. I'd say alot of 2 strokes would look like that if you pulled them down. I've heat seized a few bikes before, and just kept riding them with no problems after they had cooled down. High RPM and closed throttle positions are not ideal for 2 strokes. Best to feather throttle down etc. But yeah, long periods of WOT are also a bit scary. Could be a bit lean and getting a bit hot, but then again, how much WOT are you intending to do. Lean condition could be crank seals too?

-

Yeah, the mainshaft is part of the crank web unfortunately. It would probably be ok, as i still had to use a puller to get the bearing off, so its not a cock in a sock, its way tighter than say the gearbox shaft bearings, which can be removed by hand. But you can definitely see a depression by eye, and can feel it with your fingers. Will chuck up a pic of it tonight. I'll be doing bugger all miles, and not racing it, but would like to do the odd overnight trip. So don't want it to be a grenade. hah.

-

Think i'm gonna bite the bullet and get some new pins, rods and thrust washer things. Will assess if i'll use the rods or keep the originals when i see them. Found a set for 350nzd. I also need to order pistons and rings from the same place. So marzel get both. Im in two minds about the slightly worn crank web. It was pretty easy to slide the bearing off, and can see and feel a slight groove where the bearing was spinning. The 2nd bearing was tough to pull off over it though, so it not like its super loose. Wondering whether to press the new bearing on with some bearing locker and send it. Or track down another crank web. (Which i cant seem to find one by itself, and sending a whole crank shaft is $$$, and it could also be fucked. Nothing i touch is ever straight forward like ol Alan Millyard. Everything comes out "just perfect" for him. hah. Anything i touch come out "propper fucked"

-

The pins have a larger journal, so not just a straight bar. Could get some machined, but again, i have zero faith in any local engineering companies. I could probably buy a brand new complete H1 for the price they'd charge for one crank pin. Ive got new bottom and top end bearings, but from what i can tell, the factory rods are really good so I should re-use those I you can. Can get kits with rods, bearings, and new pins, but they're like 300usd. ouch. And i'll only be using the pins! Took off all the oil slingers, only managed to destroy two screws. They were full of aluminium paste, bits of bearing cage, and just general goop. Super yuck.

-

Right, have been waiting for everything to turn up before ripping into the crank. So it doesnt come apart and stay apart forever.... Got the bits and pieces i needed for my press, got the bearings and seals for the crank, and got the pullers i needed. First step, remove oil pump drive gear, primary drive gear, ignition pickups and the stator. Jesus the stator was on there. Had rusted onto the taper. Managed to get it free without breaking anything. Tried all sorts to get it off. But patience prevailed in the end! Next step was to score and mark the webs so i get it close when pressing it back together, and put the webs in the right order! Press it all apart! Pull inner bearings off: All stripped: I've got the webs soaking in evaporust to get rid of the surface rust: So, looks like i need a crank pin, and one of the center pins is a bit worn, looks like a bearing has been spinning. Its part of the web, so may need a new (second hand) one of those too. Will have a think. Not too bad to press apart, though i suspect that is the easy bit. I've got all my plated nuts, bolts and brackets back, they look the biz, will throw up some pictures soon. I've also blasted my replacement cases, these have alot of heavy corrosion unfortunately, so aren't gonna be aesthetically mint. This is a 50 year old bike though, so i probably shouldn't worry about minor stuff like that. Will get some pics of these up in the next update. On the hunt for crank pin(s) now. The places that sell them seem to all be out of stock. hmmm.

-

Haha, he seemed really helpful. I'm not running that ignition system anyway. Was just for curiosity's sake. Turns out it was a modified Suzuki gsx unit. Which you're welcome to have @holdenman if you think you'd use it.

-

My laverda had an ER&D. I emailed the dude and he was very helpful. I can pass on his email if you'd like.

-

Most of them removed with the twin nut trick and a bit of heat. The others needed some vicegrip help. This last one, jesus was it tight. Probably spent about 2 hours on it trying not to break anything. Got it out half way then it just broke off. Half tempted to get some stainless rod and make my own stainless studs. Probably cheaper than getting a single one from the states.

-

Still plodding away with this. Waiting for parts to arrive from overseas. Have been preparing everything for sending off to get plated. Hours on the wire wheel. Turning shit like this: Into shit like this: Should yield the best results when i get them back from the plater. Got frame completely stripped down ready to drop to sandblasting and powdercoating. Drifted out swingarm bushes, will be replacing those Turns out pistons are toast too. One of the ring lands is pinched, and i cant get the ring spring out. Shouldn't be like that, so will get a new set of pistons. Barrels have some vertical scoring, but it had really good compression beforehand, so will just give them a light hone, and put some new STD size pistons and rings in it. I'm not going to be doing mega miles, so marzel keep it standard size. Here is a pile of junk. Oh yeah, so my new cases didnt have the cylinder studs in them. So i had to pull them out of mine, What misery. They had a bit of a hard time with the vicegrips, and you can see there one of them broke off. Fortunately only one, but yay, more $$ and delay to get a replacement one. I do enjoy the misery though. And i'm genuinely excited to get this back together and running. One of my dream bikes.

-

Chur, will make sure i'll get >120ID. h1 is 110. So good we checked!

-

@cubastreet Should be all good thanks, Currently trying to secure various bits and pieces for an assortment of pressing bits. What's the OD of your crank webs? Gonna get a section of steam pipe to use for crank pressing, should make sure it can fit t500 cranks too

-

The saga continues. Did some blasting over the long weekend. Have all the barrels, heads and carbs blasted. It took a wee while! I've also managed to acquire some good condition cases for a good price. So they're on their way now. Yay. Carbs before: Carbs after: Barrels before: Barrels after: Cylinder head after: Leik new! This is using glass powder, so it leaves a finish very close to vapor blasting. It doesn't mar or hold dirt like the "furry" sand blasting finish. Ideal!

- 44 replies

-

- 14

-

-

Rad! I've got a 71 aswell. Just in the process of giving mine a wee refresh. Some new carb rubbers and intake rubbers along with new cables. Super keen to help you rebuild your crank! Currently sourcing bits of steel to help with crank pressing

-

Yeah man. Will let you know when im gonna tackle it. Feel free to pop over! T500! Rad! What year?

-

I'm gonna have a crack at rebuilding the crank myself. Allen Millyard has a very confidence inspiring video on rebuilding his H1 crank. I've got 2 H1 cranks and a couple of twin and single cranks in my list to rebuild. So if I can learn how to do it, maybe I'll be the next two stroke crank guy in NZ? probably not. But at least I won't be paying someone else top dollar to fuck it up! Only have myself to blame. Gonna use the money I'd spend on rebuilding a crank buying the required tools etc. As for machining the cases, looks like I can get a tidy set of cases between $400 and $600 to my door. I very likely won't get any change out of $18k getting that stuff machined locally. Every experience I've had with NZ people in the trade seem to: Have a "I can't be fucked" attitude like they're doing me a massive favor or something. Dude, I'm paying your for a service! No need to be like that! Be eye wateringly expensive Or they fuck it up anyway and I have to get it redone or buy a replacement So I'm very reticent to pay someone to do it (repair cases or rebuild crank). When at least if I do it and fuck it up, I've only got myself to blame, and I haven't outlaid heaps of money for the privilege.

- 44 replies

-

- 15

-

-

I stripped the engine down to get the crankshaft out. Oil check valves are definitely chooched: Bloody murder! Guts out: Not only were all the crank seals as loose as chatter rings, one of the bearings had completely collapsed. You can see it next to the stator on the right side of the crank in the above pics. I'm amazed this thing ran at all. However, there is some bad news... Because of this collapsed bearing, its actually had been spinning in the crank cases and has wallowed out the bearing surfaces.... Shits dicked jim. Theres about a 0.5mm lip there. I know there are various ways to fix this, like peening some divots in the surface to raise it up then locktite 620 the bearing in, but that feels a bit michael mouse, and it would always bug me. Plus, seeing one can still (relatively) easily get casings, I'm on the hunt for some good cases now. Good news though, i've got everything i need to do a bottom end rebuild on its way. So hopefully i can source some good cases soon and progress this revival!

- 44 replies

-

- 17

-

-

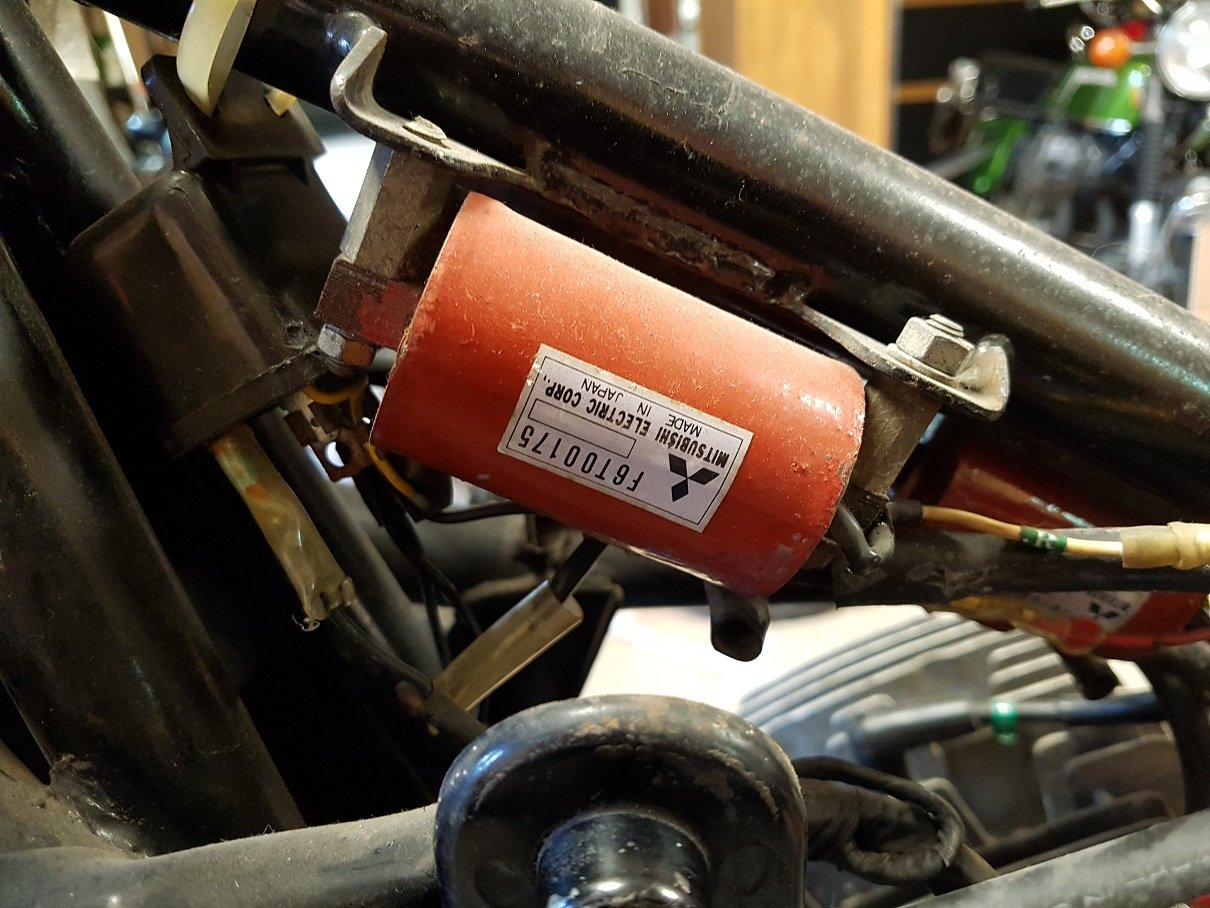

So yeah, found the problem why it was running so bad: /mitsi ain't that bad. But yeah, the crank side seal is chooched. Like zero crank compression, all comes out the side seal. Can hear it huffing out the side! I could just replace that i suppose? But the other seals are probably not far behind. So engine out it is! I'll get the cases blasted while i have them apart. So hopefully the motor will look awesome once its done. A bit of a shame the frame looks like this: Ah well, better strip it all the way down and get the frame blasted! Not bad for a quick carb rebuild eh! lol. Nothing is ever easy Also, here is the blue 1971 H1a drum front, back when i picked it up with @Beaver and @kicker back in 2015! It looks like a wreck, because it is. It is about 95% complete though. So if anyone knows of any parts, lemme know! As i'll hopefully be cracking into this later this year.

- 44 replies

-

- 22

-

-

-