-

Posts

3,970 -

Joined

-

Last visited

-

Days Won

1

Content Type

Forums

Downloads

Events

Gallery

Everything posted by Dell'orto

-

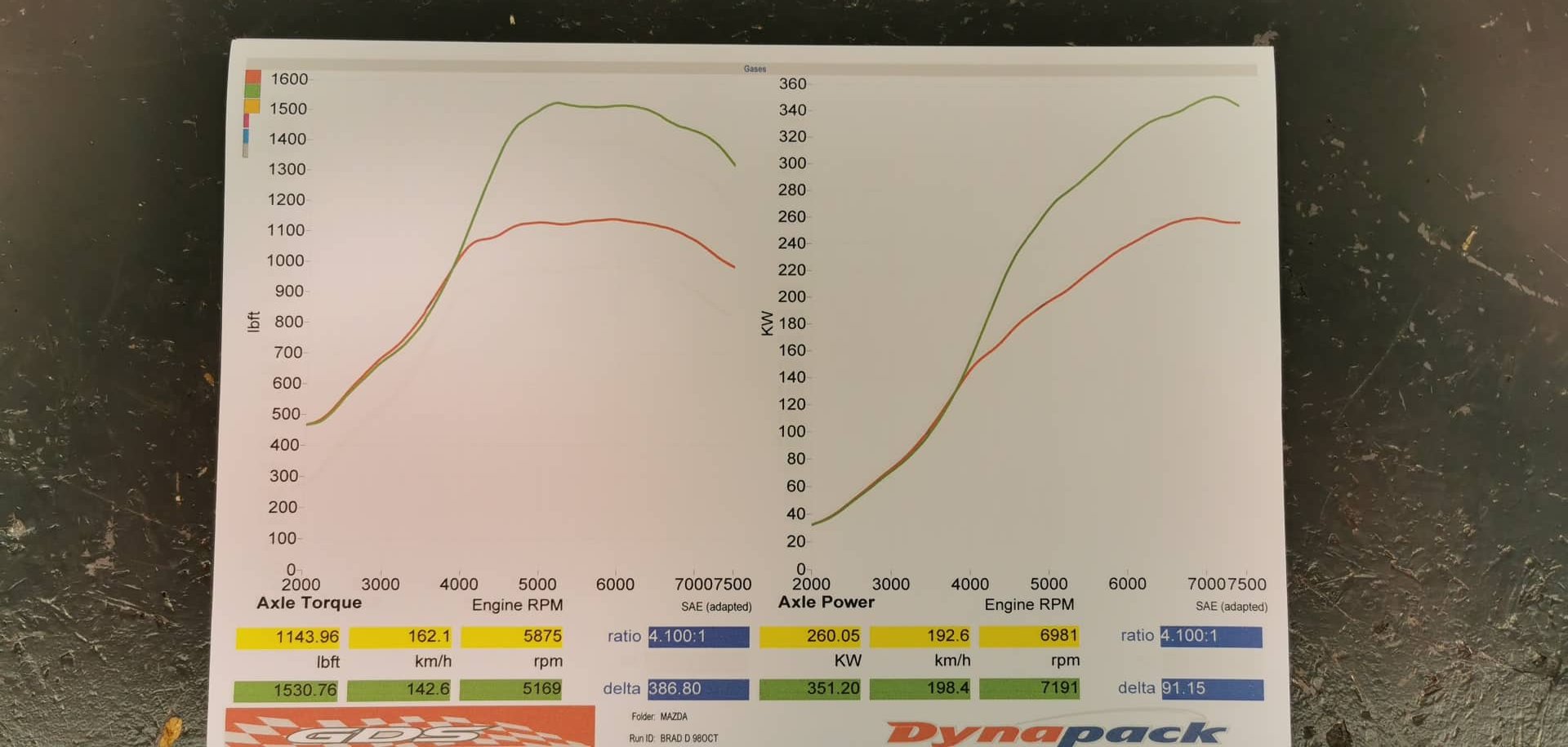

A few months pass and I finally get a chance to get away from work so I can finally get this thing on the dyno. Naturally, there are a couple of minor last minute tidy up jobs we needed to do, so ended up working until about 1 am the day of the dyno to get it all dusted. Nothing like a bit of deadline pressure to get the adrenaline going! Anyway, after what seemed like an eternity of driving, we ended up at GDS Automotive and unloaded the car. It was quite cool having a chat to one of the former top import drag racers from back in the day and I pestered him with various questions about the GTRs that he was involved with way back when, until it was finally time to get tuning. It was all pretty uneventful, the car behaved the entire time - testament to the job Jon did in building it (and me for the component selection haha). I had a fairly lofty goal of 450hp at the wheels, which I figured we'd probably have to lean on the turbo to produce. So you can imagine my surprise when we went into the dyno cell for the second to last run and seeing 345kw flash up on 18 psi! Glenn gave it one last run with 19psi (the maximum boost pressure he felt comfortable with - stock seals and undowelled) and it put down 351kw/470hp at the wheels. Pretty fucking stoked as you'd expect, and it sounded super crisp on the dyno https://imgur.com/rdeTcTW I took it for a little drive once we got back to Jon's, and couldn't stop grinning the entire time - only a little shady given the car still wasn't complied for NZ roads by this stage, but whatever, it's only illegal if you get caught right? Did the last couple of engine bay tidy up bits (ie install the FEED manifold cover and polish the strut brace) then stood back and admired 18 year old me's dream car Did one final video to keep my enthusiasm up, then had to jump on the plane to head back home again....the last time I'd see the car for several months as it would turn out. https://imgur.com/dKj7OpA

- 160 replies

-

- 18

-

-

-

Tomble's 1983 Starion GSR-X fumbling / hand-holding / discussion

Dell'orto replied to tomble's topic in Project Discussion

Petone Radiators do chemical cleaning on fuel tanks, weren't super spendy from memory. Drop it off, pick it up, zero fucking around with trying to get chain/nuts out again. -

Right, so a couple of months pass with little finicky wiring stuff being done, and the last of the fab work done. A big V mount set up wasn't in the budget, so Jon made new pipework to run from the GReddy elbow to the existing GReddy cooler, and welded an elbow to the turbo outlet to make a fairly short straight shot into the cooler. Now with the power figure I had in mind, a measly 3" exhaust would never do. So we made the call to go 4" the whole way - 3.5" outlet off the turbine housing necks up to 4" as quickly as it could physically fit It runs into a 4" Adrenalin R centre muffler, then back to the existing 4" section (Which actually turned out to be like 96mm, weird) with the Apexi muffler. https://imgur.com/0i3fcX6 Nice and tucked up, heaps of clearance! Now it was ready for the first start up https://imgur.com/h0DfDBE Naturally, it fired up super easily, even with the base tune on the Link. A little more fettling and it was time to hit the dyno!

- 160 replies

-

- 18

-

-

-

Yeah I think with how mental the prices have gone I'd probably break even if I were to sell it, which is insane. I'm sad that you never got to complete your highflow twin project with it, that would have been super interesting to see. My turbo encyclopedia friend is friends with Andre too, so have been keeping tabs on it. I still cry every time they put a new video up of it though

-

Back to the story at hand - with the motor now ported, it left me with quite a dilemma. I bought this car with a specific budget to get it all done and dusted. I procrastinated for a few months while figuring out the next step. I even debated using the stock twins and the existing bolt on stuff, but deep down I knew that the stock turbos would just end up hurting the motor. One of my other good friends is a bit of a encyclopedia for turbo knowledge so I turned to him for advice. I was after something that could flow 400-450hp without giving away too much response. The ideal turbo would have been the Borg Warner EFR8374, but I couldn't afford a $4500 turbo. So the next best option was this guy: A Borg Warner S300SX-E, sorta the poor man's EFR8374. I chose a slighter smaller than usual 1.0 AR twin scroll turbine housing in an attempt to keep the boost threshold at a reasonable point, at the expense of some top end power. Given the most powerful car I've owned before was a 220kw turbo 4age, giving away some horsepower wasn't a real concern! I made another trip up to Auckland to dress the block up and install the motor - the turbo looks fucking huge compared to a bare bones 13B! And pretty snug in an FD engine bay too Because pedantry, I replaced most of the bolts on the motor, and engine bay, with shiny new gold passivated ones. I also splashed out and bought new coolant and washer fluid bottles, as the ones in the engine bay were all fucky. I also made the unusual (apparently) call to retain the stock OMP. Everybody says they fail yada yada yada, but I've not seen any concrete evidence that the electronic ones do. And also modern ECU tech can control them, so why the hell not? Modern ECU tech also means I ditched the Power FC once again, but this time replacing it with a Link G4 plug in It also meant a decent fuel system upgrade in the form of 1050cc primary injectors and 1550cc secondaries fed by one of the other wonders of modern tech, a brushless drop in fuel pump, capable of suppling well over 500hp worth of fuel. Thank god the days of Whinebro pumps are over! With this in the hole, only minor fabrication was needed to get it ready to fire up!

- 160 replies

-

- 18

-

-

Honestly, had Jon not attacked it, I wouldn't have bothered. I knew they test ran them, but this was the first one I'd seen pulled apart. It was perfectly fine for what I initially wanted, rotors weren't terribly off either. Have seen some big mismatches on old motors though!

-

So both Jon and I are rotary guys from way back - we met back in the 90s while both driving FCs, and hung out in Paraparaumu. People from the region will know of the reputation it had for breeding some rowdy, rough, rugged and the occasional pretty quick rotary. Legend has it the very first rotor DX came from there! Naturally because of this, Jon wanted to build a bridgeport motor for this car. I wasn't super into the idea, as to do a bridgeport justice, it'd need way more serious gear than the car came with. Plus they aren't the most user friendly things for low speed, around town, general cruising, and I really just wanted something pretty quick but still usable. The stuff the car came with would easily support 220kw, which is heaps for a road car in reality. So I put the kaibosh on the idea. Stock ports are fine for what I want!. I get a message from Jon a few days later "Hey, it looks like they must test run these crate motors" Ahhh, why do you say that??? 'There's a bit of rust in the cooling jacket..." Oh FFS, I guess this is happening then. I got many pic updates over the following days as he quite gleefully hacked into my BRAND FUCKING NEW irons Now the first issue that I'd need to tackle anyway, was a decent clutch, because even a mild tune REW would torch a standard clutch without much hassle. No worries says Jon, I've got the old clutch from my Skyline, it'll be perfect for this. An OS Giken TS2B twin plate, with the necessary pull/push converter. Had done sub 1500km before he did a big upgrade, so ideal, albeit overkill for what I wanted. While it was in bits, I figured that I might as well get it all balanced, just for peace of mind. So the whole rotating assembly was sent off, returned all matchy matchy, and duly assembled.

- 160 replies

-

- 15

-

-

-

So obviously the motor was pretty much junk - the eccentric shaft was about the only usable part. This wasn't too much of a problem, as the car was comparatively cheap, and I'd bought it expecting to rebuild the motor anyway. We priced up all the parts, and it was going to be about 6k to do it correctly. I mulled on it for a while, and decided for not much more money, a crate motor would be a far better option. All new plates, all new housings, as well as all the little fiddly bits and pieces that come with the crate motor just made it a much much better option for longevity. After all, I just wanted a nice fun weekend toy that I could cruise around in! Also while the motor was out, I decided to fly up to Auckland and give the engine bay a quick respray, as it was in fairly awful condition. Rotaries and their under bonnet temps tend to melt paint off, and obviously this thing had seen some time at race tracks! So for a real quick and dirty spray job, it actually came up really nice. And this is where things started to spiral out of control...

- 160 replies

-

- 23

-

-

Conveniently, the car was in Nelson, and I'd actually booked a trip there for the school holidays with my daughter, so I paid a deposit, then a few weeks later went to go check it out. Now my original criteria were: * Preferably sub 100k, but not critical. - 124, close enough? * Closer to stock bodywise, the better - aside from a vented FRP bonnet and headlight cover, yep * Not red - yes! Mostly. * Unfucked with interior - bolt in roll cage and the rattiest Sparco seats I'd ever seen, and typical JDM trinkets ruggedly mounted all over the place, close enough? * Not really after a project, ideally something I can turn key and go - uncomplied fresh import with low compression, close enough? However, my best mate Jon offered to build the car up for me so I figured, what the hell. The car had lots of cool bolt on bits, like a 4" thick GReddy intercooler, HKS downpipe into a Knightsports highflow cat and 4" Apexi tail section, Power FC - all the typical things you'd see on a mild tune FD from the mid 2k era really - so I figured that with a fresh engine and tune, it'd be a bit of a weapon! It duly turned up at Jon's workshop about a month afterward, and he sent me some pics that in daylight, made it look far worse than I'd recalled. Now epic magnetic JDM service stickers aside, it would appear that honorable previous owner-san was a bit of a tinkerer - things like the odd cut outs in the bumper, and some hodge podge installation of electronic gizzmos inside the cabin would suggest this. But it also appeared that he had a crack at replacing the front crank seal, which if you aren't careful with, can lead to bad things happening. Bad things such as this:

- 160 replies

-

- 16

-

-

-

So fast forward almost exactly 3 years... I'd been buying and selling projects to try and scratch the itch, but to no avail. I'd also been busting my ass to try get myself back into a financial position similar to pre divorce. I'd been fortunate enough to buy a house just before the market went nuts here, and made a bit of pretend money thanks to capital gainzzz. Because of this, I began the hunt with some fairly specific requirements, essentially wanting to buy another car just like this. But I quickly found that the FD market had changed a fair bit, with NZ stocks being mostly worn out shitboxes for 15- 20k (and I paid 12 for the original car!) and a similar spec car from Japan being closer to 30 by the time it landed. As the months went on, I started to get impatient, and almost went down the STi route, but then this gem cropped up on TM And by gem, I mean, rough as guts bag of shit ex Japanese track day hack, but the price was right.

- 160 replies

-

- 24

-

-

-

With the help of a bunch of friends, we got the motor back in the hole, and all plugged back together. All that was left to do was turn the key and enjoy the smooth purr of a fresh 13B REW! Except that didn't happen. For some reason, the thing was still running pig rich, much like it did prior to the rebuild, and the reason it spent a lot of time at PPRE. I spent a bunch of what precious little spare time I had trying to diagnose it, albeit it fairly haphazardly. I had no money to take it to a workshop, and after the experience I had with the last "rotary specialist" I was fairly unkeen to try again. So I offloaded it, stupidly cheap in hindsight Sometimes when you sell a car, you absolutely regret selling it to the new owner, but in this particular instance, it could not have gone to a better home. @ProZac found the issue, that even so called rotary experts couldn't pick right from the outset, and I also learned a valuable lesson to verify things yourself, and not rely on previous owners notes. Zac's 1998 RX7 - Other Projects - oldschool.co.nz for those who never read it (shame on you if not, it's a wealth of info) Obviously I followed this with interest, because goddamn it, that car was so immaculate and I loved it. Was secretly hoping to be able to buy it back one day, but unfortunately it was onsold before I could ever hope to have the money for it. It's new owner has also done some amazing things with it, and its now at a level that I could only ever have dreamed of having it at. 13B Rotary Rich VS Lean AFR's | Our FD RX7 Project | Ep 2 [#BUILD] - YouTube you may have heard of HPA, they do some cool shit

-

As the budget also wouldn't allow for new housings and rotors, I picked up a secondhand matching rotor, and a secondhand housing. Haynes Rotary were doing housing resurfacing at the time, and I figured for a couple of hundred, it was worth investing in the process. Both housings came back looking absolutely stunning Then I went to Custom Works (I'd left there by this stage, divorce etc took its toll on me) and got Hayden to help me assemble the block after hours Reassembling all the ancilliaries was fun, snapped the OMP lines so had to spend more money I didn't have to put it all back together. With all the shit bolted on, you couldn't even see the damn things!

-

Oh hai. Figured after the better part of a decade I'd update this. In the end, I chose to rebuild the existing engine. Even though I knew I'd probably have to sell the car anyway, my ego wouldn't let me halfass the car like every typical rotor dickhead back then. Especially as it was so goddamn tidy. I dropped a bunch of money at my local friendly Mazda dealership (Jim @ Capital City is the man) and bought all new seals, springs and a full ($$) engine gasket set. The only components I didn't replace were the oil control rings as they were in OK condition, and at a couple of hundred each (x4) it was beyond the budget. Spent a fun couple of evenings cleaning and clearancing each rotor

-

No fucking around! Good work

-

Got another multimeter to check it with to eliminate that as the issue?

-

Looks like they prototyped the FC dash in it, interesting in maroon! Import some modgies asap

-

I have this lever/cable assembly if you wanted to upgrade, I do you bes' priiii

-

Is that Greg? Bought a few bits off him before, good dude.

-

Part it out, I need tail lights How's it for rust? They seem quite shit for it for a "modern" jap car, guess the soft tops don't help that.

-

Mattt's 1970 RT80 12A Bridgeport TEQ Corona Discussion

Dell'orto replied to Mattt's topic in Project Discussion

How good are the Trophys though! -

Mattt's 1970 RT80 12A Bridgeport TEQ Corona Discussion

Dell'orto replied to Mattt's topic in Project Discussion

J port j port j port j port -

Fuck yes, love repus!

-

- 61 replies

-

- 13

-

-

-

BOC can help you out with one

-

They're not a bad little machine, air cooled torch is a drawback though. I find mine gets uncomfortable after not long at 100 amps. But then it's duty cycle isn't great at high amperage either, so not the end of the world.

.thumb.jpg.a5b052eadcb502338fa7a85b8de95cda.jpg)

.thumb.jpg.b947e8574e71878b2baeea5b08d17e4f.jpg)