-

Posts

19,522 -

Joined

-

Last visited

-

Days Won

159

Content Type

Forums

Downloads

Events

Gallery

Everything posted by yoeddynz

-

Great progress! I think your dad needs to start a project thread on that car he's built! I hope you've showed him the wonders of oldschool.

-

Oh yeah whilst on the subject of looking after your tools.. Always make sure to drain your compressor regularly.. Whoops.. My bad. Has anyone ever put tank seal in there compressor tank to stave off/fix corrosion? I'm thinking I could pour some into mine on a hot day and seal what I'm now picturing is a moonscape of a tank floor.

-

Can you run brake and fuel lines inside the cabin?

-

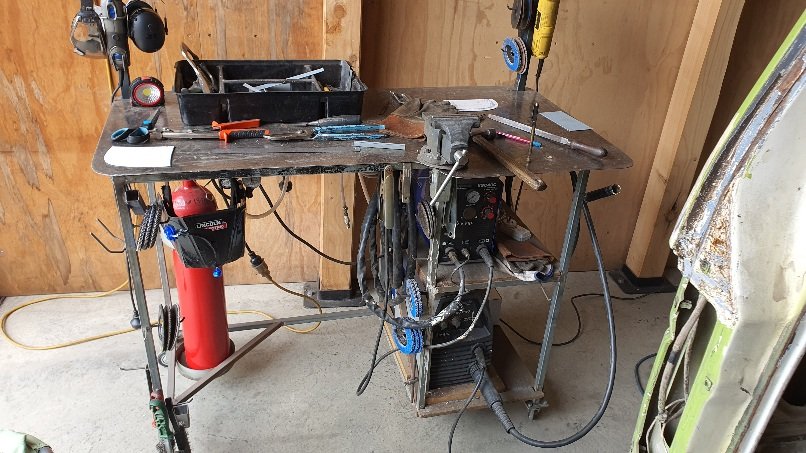

Your welder looks very similar to my Jasic (good old welders) so here's a pick of my set up that might help you?

-

Same here. I bought a 5kg bottle 10 years ago for about $250 and I get it refilled by the fire extinguisher place. 11 years ago the refill was about $35 Its now about $45~50... Apparently/maybe Co2 is less common these days/climate change is a hoax But yeah. I've used argoshield plenty in the past but fuck that cost for mig welding when half the time the welds are probably ground back on car restos or if it's a trailer build then c02 shielded welds are fine. Mig welder I use is a 180amp weldtech invertor from proline also 11 years ago. Goes well.

-

Not bad those for the money but the wheels are quite big in diameter and awkwardly shrouded which limits your ability to grind tight places and small items.

-

The ones I used often from way back when are a kiwi made linishall. Design had not changed in years. Rugged and they work really well, plus the long belt lasts a long time - important in a busy engineering workshop. Also good that you can stand right next to it and not be bending your back which is handy when you might have 100 items that all need a skim. But fucking expensive!!! * so I'm collecting the bits to fabricate my own because I miss not having one about.. https://nzsafetyblackwoods.co.nz/en/linishall-wright-linishing-machine-038-each--03054296 *like 5 k11s worth

-

Discuss here about Yoeddynz's little Imp project...

yoeddynz replied to yoeddynz's topic in Project Discussion

Man if I had attempted to tig weld those bits it would have turned into an abortion. My tig skills on small steel/stainless work is still not very flash. I'm glad that when the time comes to weld my exhaust manifold at least it'll be hidden from view -

Discuss here about Yoeddynz's little Imp project...

yoeddynz replied to yoeddynz's topic in Project Discussion

Cheerz fullas. I'm happy to entertain. Yes - Baart @RUNAMUCK would no doubt want to see a Holly and a supercharger -

4V Century V8 powered Dyna Camper Discussion

yoeddynz replied to HumberSS's topic in Project Discussion

Great reading Also... "I think a few less doobies would have helped.." But so fun -

Discuss here about Yoeddynz's little Imp project...

yoeddynz replied to yoeddynz's topic in Project Discussion

Now that's not a place for swarf. -

Discuss here about Yoeddynz's little Imp project...

yoeddynz replied to yoeddynz's topic in Project Discussion

It could be worse. I could have a vagina. -

Discuss here about Yoeddynz's little Imp project...

yoeddynz replied to yoeddynz's topic in Project Discussion

We have a strict shoes off policy for heading upstairs (although half our visitors don't wear shoes, because tasman) I still manage to find the odd bit of swarf, the worst place is in bed. -

Discuss here about Yoeddynz's little Imp project...

yoeddynz replied to yoeddynz's topic in Project Discussion

..and swarf in the workshop downstairs equates to swarf upstairs -

Discuss here about Yoeddynz's little Imp project...

yoeddynz replied to yoeddynz's topic in Project Discussion

If it turns out the way I want I can guarantee that everyone who sees it will spit their coffee out and laugh. Its going to be fun. -

Discuss here about Yoeddynz's little Imp project...

yoeddynz replied to yoeddynz's topic in Project Discussion

Oh wow- that's golden. I might have to take a trip to a steam museum/menz shed/barry haunt and drop that one into conversation. Just keep a straight face and insist its correct. Watch their faces to red. -

Yoeddynzs 1965 Hillman Imp. Dashing about with cowskin.

yoeddynz replied to yoeddynz's topic in Projects and Build Ups

Ooh its been a while. I have been tinkering away at this but other life things have popped up so this has not been high on my agenda. My dad, 89, went into hospital with pneumonia. Well he'll get looked after there. Then he got covid in hospital. Bugger. Long story short he was on deaths door, pulled through with the aid of strong anti viral technology and great staff, slowly improved and is now in a home. His body is frail but his mind is strong. So I've been dealing with that. Then Hannah and I got covid and it was not very fun. Being normally very fit out on the push bikes etc we have really noticed a huge loss in strength and lung efficiency. Getting better though. So yeah.. this engine has been collecting dust. When I tested positive for covid I honestly thought I'd deal with it for a few days and then get heaps done on the engine while isolating. But my body had other ideas. Anyway, I'm back onto it now. Quite a lot of photos to load up too. Induction time. I have decided to make something from the existing inlet runners and use a central plenum chamber with a rear facing throttle body. Try to hide the TB and use a remote pod filter to draw in cool air from somewhere other than the top of the engine bay. I have a some very funky ideas for my plenum design and have a particular look I'm chasing with the setup. Looking forward to building that. But I need to sort out injection first. Here are the stock runners, normally fed by two carbs that sit too high and would have fouled the rear parcel shelf... Interestingly this engine has a neat feature in that the cylinder heads are identical as are the inlet runners. They could be swapped side to side. This was going to help with my modifications when setting up the mill etc. in place.. Note the total lack of injector bosses.. First thing was to remove the (ugly) water jacket which was not going to be needed in my setup.. Much nicer looking and lighter too... Lots of room for a suitable sized plenum.. Very nice smooth entries into the runners.. Now I needed to start looking at injector fitment. It has to be as neat and compact as possible. The spacing doesn't suit anything I could find so the rails will have to be custom. I decided against top feed injectors because they would be just too bulky. Side feed it was to be. I had a couple of ideas. Bought another injector rail setup from a Nissan Micra K11 at the wreckers because the stock injectors have a very suitable rate (130cc) and are cheap and easy to get. I also had a set of Mazda V6, as per fitted to my Viva, gifted to me by Steve @Transom They were close and rather compact but it wasn't going to work without a lot of chopping and then the top caps with the wires set into the plastic would have been a pain to shorten and keep neat. Final nail for these was the injectors being just a bit high in flow rate (220cc) , running the risk of awkward tuning around idle on an engine with smaller fuel requirements. K11 injectors it was. But the spacing is way off and they had ugly brackets all over them. So I cut them up and ended up with just the injector housings and then played around with some 16mm tube and the mill. Bit of a test piece... The fit was spot on.. Happy with that I welded two bits of tube onto a plate of steel and carefully milled the tubes, spaced to suit the inlet spacing... a tidy up removing sharp edges with files and they came up neat.. I made a little jig to hold the injector housings onto the rail with the correct spacing so I could braze them in place.. Then out with the oxy acetylene and brazed them in place with silver solder. Note my sore nose where I had smacked it with a large branch when cleaning up a fallen tree. Hurty... Now I have some side feed rails with the correct spacing Next job was to create a place for them to fit. I needed to add some bosses to the inlet manifold and get the angle just right so the injectors would end up pointing as close to the back of the valve heads as possible. I cut up some chunks from a large bar of alloy. Then I milled them down to suit and tacked them in place... Happy they were located correctly I fully welded them in place. The inlet casting was luckily of pretty decent quality and welded nice enough.. With them welded up and solid I could machine the bosses down in one hit, levelling them off at the correct angle and making sure the faces all lined up. I made a steel jig, set at the angle to suit (because my drill mill doesn't have an head adjustable for angle... oh how I'd love a larger knee mill) Now I was able to carefully mark and drill out the injector holes, then spot face the O-ring seats.. In order to aid with with marking and checking them I machined up a little button that fitted perfectly into the injector holes... Annoyingly (silly me) I marked to first hole off wrong by 1mm and by the time I was at the last boss on that side I had to add some weld to make sure there was enough meat to house the O-ring... I learned something and didn't repeat the mistake on the other side Now I had injector bosses and the holes were pointing in the right place.. I have to hold them down in place though. So I made up some little steel bolt bosses.. Brazed them in place.. Machined up some bits of alloy, tapped out to suit the bolts and some spacers for between. Made a little clamp thingee to hold the injector rails in place along with some alloy O-rings (because well.. the rubber ones would probably have melted when I was welding) Pics explain it fine.. Phew. That's that! Up to date now. Next thing is to design and build the plenum chamber. I'm going to have some fun with this bit. It's not going to be simple because I have a certain look I want along with a fun idea I have in mind.- 121 replies

-

- 77

-

-

-

Pacman graph

-

I like the fact you've added a seat too!

-

Have you ever considered a Nikki carb with mechanical secondaries?

-

Alex's 1968 'oldman special' HB Viva discussion....

yoeddynz replied to yoeddynz's topic in Project Discussion

So stoked to see this car getting regularly used and proudly shown off. Cheers for sharing Charlie @Guzzi Rat I had a quick sift on the book of face and found another pic. Great turnout!! -

For a tractor etc id be happy to do this - but I'd be a bit worried about the heat cycle weakening such a vital part on a car that sees the road eh?

-

I think you need to talk to your neighbour about how they dress their cat..

-

I did exactly that on some screws the other day. Worked a treat.