-

Posts

10,922 -

Joined

-

Last visited

-

Days Won

6

Content Type

Forums

Downloads

Events

Gallery

Everything posted by Truenotch

-

@4AGEMAD's project thread: I highly approve of this car! Nice work. Someone must have really loved it to justify converting it so well. My dad's car is like a pre-facelift version of yours. This is the car that gave me my username. Keep up the good work!

-

Gave everything a quick clean up and set the points. There was so much crap under the sprocket cover! Gets really good spark now . Also investigated the broken stud - I suspect it used to be the other way up and someone sheared the top off when tightening the barrel down, then flipped the stud over to pretend nothing ever happened... The thread is good inside the casing, so all it needs is a new stud and it'll be good to go. the next funny thing is that the clutch no longer actuates. Maybe cleaning all the crap out has dislodged an important piece of actuating dirt? I've pulled the cover off the other side and the clutch plates and pushrod look good, but the rod on the actuator side is solid as a rock and I can't get it to disengage at all. Maybe the little ball bearing that sits between the pushrods has escaped?

-

Took the cover off and removed the flywheel to get a look at the points. The left hand coil has loose windings at the bottom... Anyone seen this before? I think it still works, but might give out soon I guess?

-

I really want vids of this thing hooning.

-

Churr. I spotted the MLM the other day... Might be worth a hoon.

-

Hey @MopedNZ, how did this thing go with the AliExpress chamber? I'm thinking about buying one as a budget open for Rahn's FA.

-

That was a decent hit on the hillclimb! I've done similar in the past - mucked up the corner before, thought I'd saved it, threw it down a bank almost instantly. Glad to see there wasn't too much damage .

-

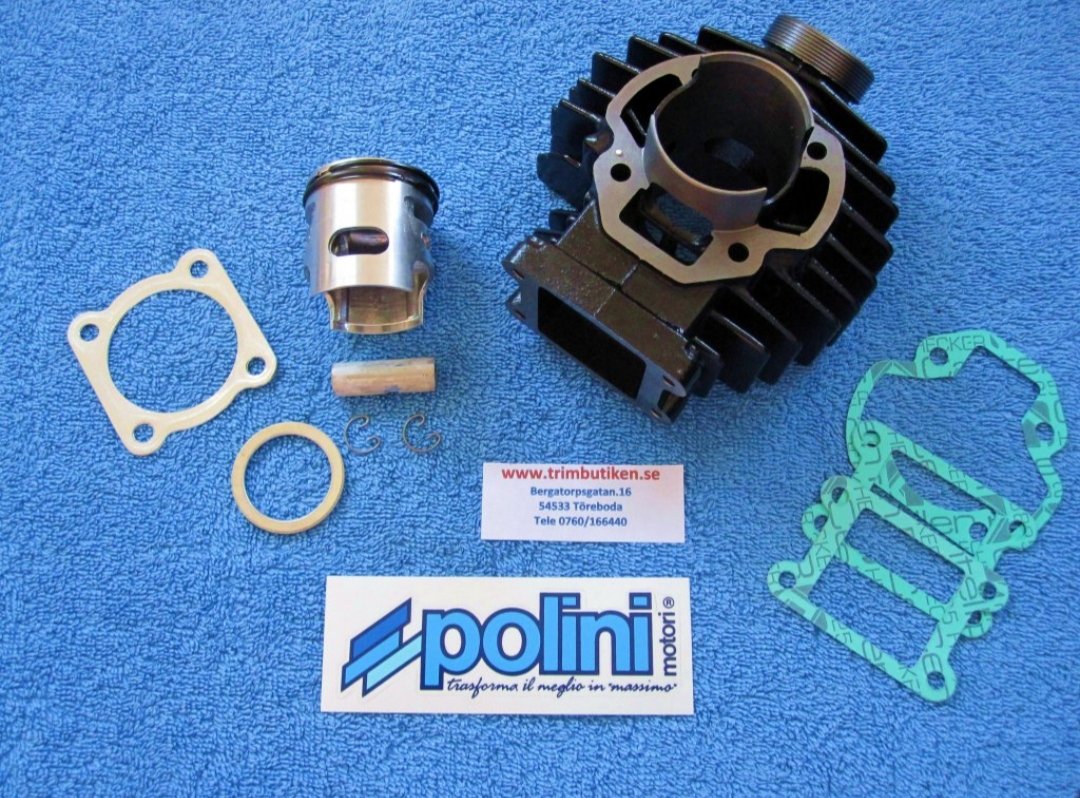

This old thing has a few demons for sure... I had it running and took it for a gentle doort up the road. It definitely doesn't run well. I suspect the points need a tickle up/CDI conversion. Then I decided to pull more bits off. Removed the cylinder, carb and reed block: Yep, you heard right, reed block. I always thought these were rotary valve. This proves they're not: The eagle eyed amongst you will notice that there's only 3 cylinder studs. #4 was super loose and was able to be removed by hand. Hmm... This seems short... The stud had snapped at the thread at some stage. There's still a hunk of bolt stuck down the hole and the top part of the stud hole is pretty munched. Looks like it'll need a helicoil. I also wondered why the footpeg was so close to the gear lever. Looks like it's been dropped in a solid fashion. So I guess I'll try to bend it back into shape or remake it with fresh bar or tube. I've also got @Raizer working on a 45mm kit like this to make it ~65cc. These ones have an inlet above the cylinder, instead of coming through the side of the crank case. This makes it easier to fit a different reed and bigger carb. Here's a couple of badboy 45mm FS1s for inspiration:

-

The final round was another cracker! We had changeable weather conditions which left everyone guessing about what to do with their setup. I qualified P2 again behind Bryce. We had an epic battle for the full 6 laps in Race 1 and I managed to come away with the win (just). This was a really fun race! The reverse grid in Race 2 was trickier for me. I started from last place and Bryce made a few early moves to put a gap between us. I made my way up to second, but wasn't able to catch him. Race 3 was WET. Jeremy Hoskins lent me a set of brand new tyres to cope with the conditions and the car was handling well, but I couldn't do better than second. Visibility was very limited during this race! So that's the series done for 2018. I ended up in second place for the series, 35 points behind Bryce in #22. The racing was close, clean and fun all season long, and proves that MX5 racing is still a super fun and affordable way to get your motorsport fix .

-

Round 3 was another action packed weekend! I qualified second, so started on P2 in the first race. I had no answer for Bryce who'd started on pole. He made a gap and held it for the whole race. Race 2 was a bit more interesting. I started from 10th place as it was a reverse grid. Managed to make a good run through the traffic and ended up finishing in 1st! It was a great battle with Bryce all the way to the finish. Race 3 was intense! Bryce and I started from the last 2 grid spots. It was a handicap race and we started with a considerable gap to make up. On the last lap we were catching a bunch - I made a move down the inside and got a good run down the straight. It was anyone's game right until the last corner. I chose the low line behind Scott's dark green MX5 and Bryce went high. Unfortunately Scott had a slow run through the corner, which allowed Bryce and Tim to leapfrog past me... End result, I finished 6th and Bryce finished 3rd to extend his championship lead. So that's another round done and dusted. On to Round 4!

-

The problem is that anyone can register a car into their name and all they need is the p;late number to do that. So by that logic people could register a car in their name, then claim that they own it. I think this is how Fair Go looked at is as Joker mentioned earlier. Here's the guff from the NZTA website: https://www.nzta.govt.nz/vehicles/how-the-motor-vehicle-register-affects-you/your-responsibilities-as-the-registered-person/

-

It's a K24 with a K20A head and an Eaton M90. Made 200kw at about 6.5psi on a pretty conservative tune - would make far more with water/meth injection, but it's super fun as it is. Build thread: https://nzhondas.com/topic/183910-k24k20-dc5-m90-what-could-go-wrong/ Here's a pic from part way through the assembly:

- 418 replies

-

- 8

-

-

-

Eastcapescapade 2018 November 9-10-11

Truenotch replied to johnnyfive's topic in Upper North Island Region

The East coast is the West coast of the North island. -

Eastcapescapade 2018 November 9-10-11

Truenotch replied to johnnyfive's topic in Upper North Island Region

Sure. As long as the madam will let you out for the East Cape ride. -

Eastcapescapade 2018 November 9-10-11

Truenotch replied to johnnyfive's topic in Upper North Island Region

Fuckjobs. -

Eastcapescapade 2018 November 9-10-11

Truenotch replied to johnnyfive's topic in Upper North Island Region

I'm planning to be there. Need to talk to Rahn again, but I think she's pretty keen too. -

Sounds like there's a few bleed screws in the system. There might be some useful info here: https://www.meganeownersclub.co.uk/forum/viewtopic.php?f=2&t=12790 Also: https://www.renaultsport.co.uk/forum/default.aspx?g=posts&t=83743

-

If it's an LSD and has a hole all the way through the centre, punch it out from the other side. I assume the diff head is stuck in the housing as a result?

-

You can't get a cert for a full cage. A full cage requires a Motorsport authority card which means the owner needs an MSNZ licence, the cage needs to be homologated and the car needs to do a minimum of two events per year. It needs to be checked over by a Motorsport scrutineer with an A on their licence (A means they're allowed to do authority cards). I think you can also do an authority card through the drag racing associations if the car is built for straight line racing.

-

Those are much better! This way the mount is suspended on the urethane which allows a bit of flex up and down (as opposed to your current ones that only allow flex downwards).

-

The engine mounts in my racecar were a similar style to this (albeit much lower profile). It always vibrated a lot and the bolts took a hammering. When I removed the engine it had a broken bolt on one side and had pulled the thread out of the other... So I had no bolts holding the engine down. The engine basically tries to yank the bolts out as it twists with torque. I've now gone to an isolated rubber Rover V8 mount. Will report back one day when the car is going again...

-

Not oldschool related, but what are the rules about cutting / re-shaping the ribs under a bonnet? My neighbour is adding an M90 supercharger to his K24 powered Honda and it needs a bit of work to get the bonnet to close. It needs a notch in the centre rib from just above the round hole down to the bottom of the dented part (they've been experimenting with a hammer to re-shape it). Is there a rule regarding bonnet ribs? The hole is 130-140mm from the bonnet catch if it makes any difference.

-

If the clutch cover is thicker overall the fingers could be running on the bearing full time. This would only be the case if you've got the wrong pressure plate / clutch cover.

-

Yeah, it sounds like the release bearing could be your issue. If it's too long it won't disengage properly. The only other thing that could cause it is an incorrect pressure plate that has the wrong offset to the fingers. C56 and C52 gearboxes are the same aside from ratios and sometimes starter position.

-

Tow a trailer from Christchurch to Milton/Dunedin?

Truenotch replied to noel's topic in South Island Region

Maybe get in touch with iDrive - they might have a car heading that way with a tow bar. http://idrivecars.co.nz/