-

Posts

2,021 -

Joined

-

Last visited

-

Days Won

1

Content Type

Forums

Downloads

Events

Gallery

Everything posted by Bearded Baldy

-

Napier auto supplies i think it was sold me one for really good price a year or so ago..was new and for a customer. I remember nissin king also doing new aftermarket.

-

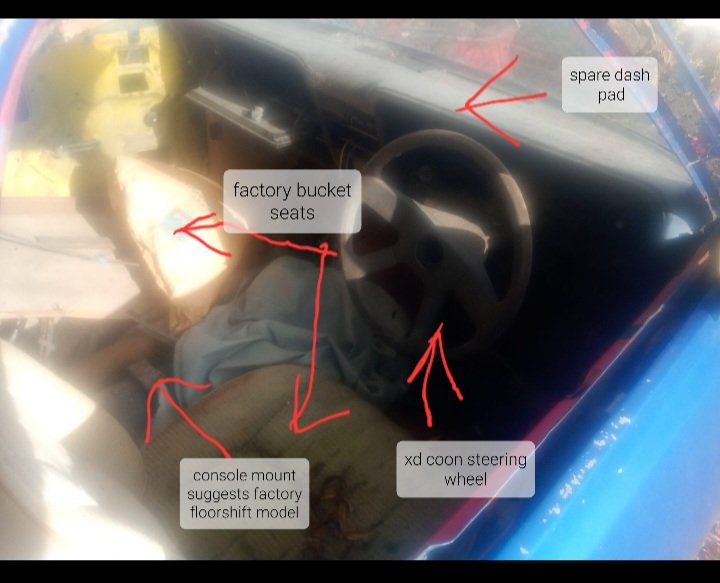

Never mind that bland post there @RUNAMUCK,must have left the screen open when i went to sleep and when i slapped the screen to shut down the morning alarm i managed to qoute and repost the one above it. Anywho, this blue pile of bog has revealed some real gems this morning, i braved opening the doors and seeing if the floor would collapse, it sagged but didn't flop so happy days. It has something so rare i was not aware any survived the 80s, intact crack free A pillar covers! And looking under the door card lying on the passengers side was.... Spare tail lights, front indicator lenses, a bag of factory black inner door handles, new gearstick boot retainer, unbroken lower steering column cover (normally all cracked or drilled for switches). All were in bags too so somebody had a dream for this.

- 90 replies

-

- 11

-

-

Though it looks like a weak viscous coupling on the front, haven't looked into it.

-

-

Tech Spam thread - because 1/4" BSP gets 5 hand spans to the jiggawatt

Bearded Baldy replied to Roman's topic in Tech Talk

Did you win? I have had success with standard issue cocacola poured in the bores and ignoring the problem for a week. -

What is in the back of the old suzuki cappucino?

-

..

-

Oh. And the COMPLETE steering assembly, box and links, idler blah blah blah.... was in the tray! Another day tomorrow to deal with that.

-

Good stuff. In here is a set of gxl rectangular headlights and buckets, late xc to xf wide radiator i can use for mocking up as the copper car has the older narrow rad. And the ute/van specific stainless upper doorframe mouldings and rubbers i can sell off. Here we have yet another 5 position wiper switch for the hoard. And another clock. Dash is in very good condition really so will dismantle that part nicely, the rest will be cutting discs and kicking.

-

Got to vegas just after 10am, had the front end assembled and ready to go on trailer by 10:45 and then noticed the hire trailer has no winch. WTAF! Thankfully fella had an old excavator so with some precision chaining, nudging and forcing, the ute was manhandled onto the trailer. This thing is so rusty that when i climbed over the front to tighten up the steering idler the frame folded down a couple of inches! Anyways. Got it home and off the trailer, swapped the rear destroyed tires for some not so nasty, might hold air ones. Then had a walk around and made a plan. It will definately never be on the road again so i will be cutting it up and stripping it. Pics of perfection. Cant have rusty sills if the sills aren't there. BadChad must have practiced here in NZ. Tray and fuel tank zone. Only a little bit bent!

- 90 replies

-

- 12

-

-

-

-

Fecking got the bastard. Forgot home much of a prick drop arms are to break free in place. Bonus though, found a very cold box of double brown which had made its way into the shed fridge at some point. So will work my way through half of those then an early night for me. Leaving at 9am for the super long drive to the big smoke of rotovegas. Updates to come by lunchtime all going to plan. No pics because it is dark, cold and wet.

- 90 replies

-

- 10

-

-

-

-

Well. Shit. I couldn't buy just the idler arm pivot on its own so ended up buying a second steering assembly minus the box. While laying everything out last night i thought the 'racks' looked different. Ignored it. Lay them on the bench this arvo and sure enough the one i got as a spare with the car is shorter than the newest one. I just ran the part number on the steering box attached to the shorter one and...... that setup and box is from a 67 to 70 mustang. Which won't fit. So tonight i have to take out the power steer box out of the bronze bitch and try not to spill manky old p/s fluid everywhere. I am one rounded pipe fitting away from having regerts about buying the ute....

-

Name of the book please @RUNAMUCK. Sounds like one i need on my shed bookshelf.

-

Things wifey didn't notice when i showed her the listing on the tard. Or she didn't care about. Not sure which tbh. Still. Could have blown $200 on booze instead, worst case here is i get my money back in scrap value.

- 90 replies

-

- 15

-

-

-

Could be a lot worse. Seems a shame to put them on a donor vehicle. Might have to swap them over once i have everything on the same property. Be a couple of weeks until i get the blue one home, will update status on whether it becomes a donor vehicle or a really really REALLY long term project once it has had a waterblast.

-

So in light of buying this.... I have had to pull finger and go through the parts hoard and see what is there to get it rolling so i can get it on and off a trailer. Later xf hubs arrived today so i gave them a steamclean before i left work. Look fine for 40 year old cast iron. Then dug out some fancy shmancy trw rotors that have been on the shelf for the best part of the last 10 years. Unfortunately 6 months of that was in a leaky shed, only surface rust but still annoying.

-

Tech Spam thread - because 1/4" BSP gets 5 hand spans to the jiggawatt

Bearded Baldy replied to Roman's topic in Tech Talk

Spray on oven cleaner and a hard scrub after, then spray with a clear urethane? -

Discuss here about Yoeddynz's little Imp project...

Bearded Baldy replied to yoeddynz's topic in Project Discussion

No idea what a 911 sounds like, but that does sound pretty horn! -

Cheers @cletus, well known in the falcon circles that the aftermarket balljoints have less movement than the originals but i have a plan. I am hoping that since i am only going low springs this time around (whenever it actually gets on the road again) that worst case scenario i lower the bump stop a touch, best case scenario is some getting in some globalwest control arms and them passing lvvta checks with no hassles. The globalwest arms have screw in balljoints with much greater travel alledgedly. That style. Actually, looking at the prices on those that may be worst case scenario lol.

-

Has taken a bit of searching but managed to get a pair of front spindles from an XF falcon for a decent price. Used to be everywhere but the speedway guys hoarded them and everyone wants big money for them now. They are slightly taller than the pre Xd ones so will change the camber curve a bit, similar amount to doing a shelby drop apparently, and also have a slightly different steering arm, rumour is the geometry was upgraded to better suit radial tyres. Some people use the xf calipers as an upgrade to the xw to xe coons, but aside from being lighter as they are alloy, they also flex more than the older ones. So as part of the deal i told the guy he can keep the calipers. I scored a set of dimpled and slotted hub/rotors on clearance years ago which are waiting on the shelf, unsure if i will use these and some more modern calipers, or let my imagination go wild and mod some hubs to fit bigger slip on rotors.

-

15yr old baldy found out that you can't use a paperclip as a fusible link... and the fence staple turned from grey, to smokey yellow burning galv really quick... found the short before it melted everything though!

-

My take on it is so long as i can see the fuel and pressure rating and it isn't perished, and it is a like for like replacement, send it.

-

Not sure how far @Roman has gotten with his, i have managed to import a set of calibrated orifice plates and the pts digital manometer. Could have gotten a cheaper manometer but the pts one is a nice bit of kit, and has its own software program for easy datalogging. Have not cut a single board yet as far as building it goes.

-

Bahahahha that is the precursor to building shed number 3!