-

Posts

1,095 -

Joined

-

Last visited

Content Type

Forums

Downloads

Events

Gallery

Everything posted by Jusepy82

-

Hey man. I just happened to buy a 250es aswell. You dont happen to have a cdi for one or know what cdi's will replace the OE one.

-

@MightyMoose one like yours brother !

-

I think you and I may have the same addiction !

-

Awsome work man , sounds nice !!!!

-

77 ford escort panel van. Jusepys 77 ford escort panel van

Jusepy82 replied to Jusepy82's topic in Projects and Build Ups

Did a little bit of work to the old girl today. I needed to remove the metal that sits around the head light at the top of the wing. Drilled out all the spot welds on the wing to free up the curved inner pannel so I can make a new one. Dave's garage on YouTube shows you step by step how to make the pannel parts. Not much of a update but worked out well , amazing what you can do with the proper tools. -

77 ford escort panel van. Jusepys 77 ford escort panel van

Jusepy82 replied to Jusepy82's topic in Projects and Build Ups

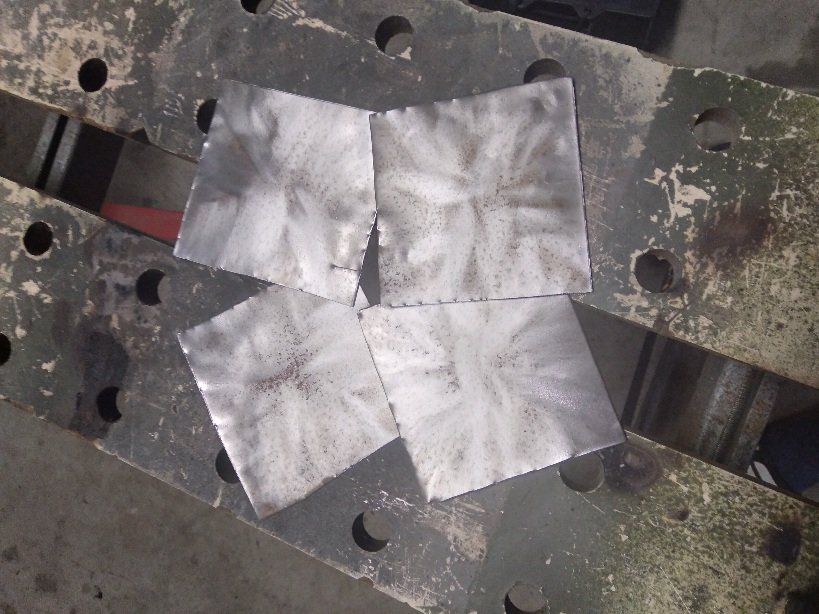

Bit of an update. I'm practicing my welding before cracking into it again but I brought a tyre changer from super cheap. Soooooo I stripped down all of my hotwires ready to clean up now. Chur -

Bloody hell , thanks bling ! I will do exactly that mate !

-

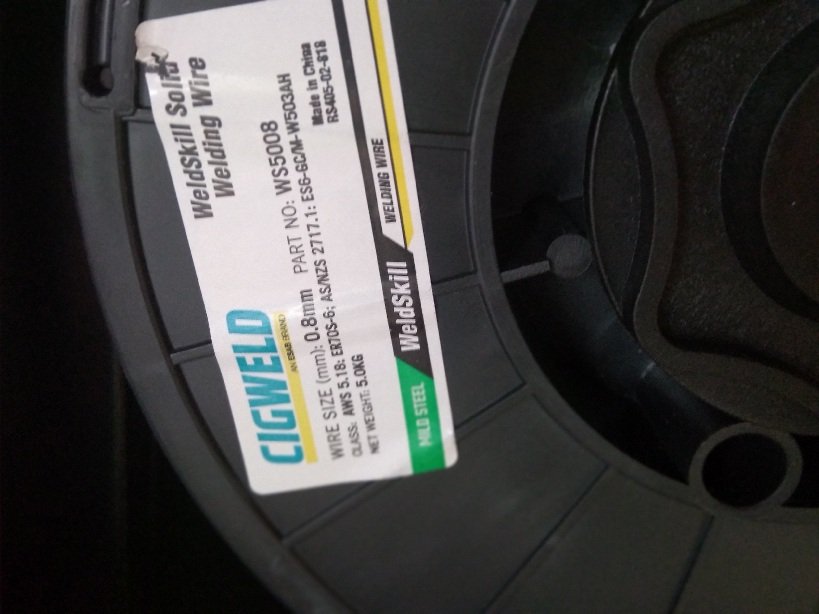

Seems to me I fucked up buying .8 wire for panel steel. I brought it because one of my mates recommended it for it for one reason or another. I will turn down my wire speed gradually and see what the welds look like later today and post them on here. Failing that I will suck it up and go and buy some .6 wire. Chur to be continued....

-

Yeah heres the rear of the panel. Ah yup only two knobs one for voltage and the other for wire speed. The other small one is for arc welding.

-

@JustHarrydo you think I should turn the voltage down alittle more ?

-

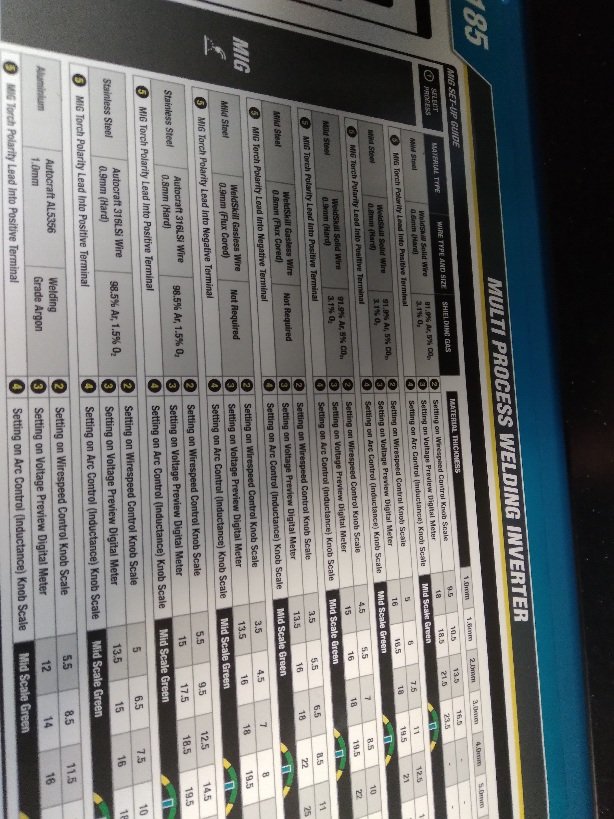

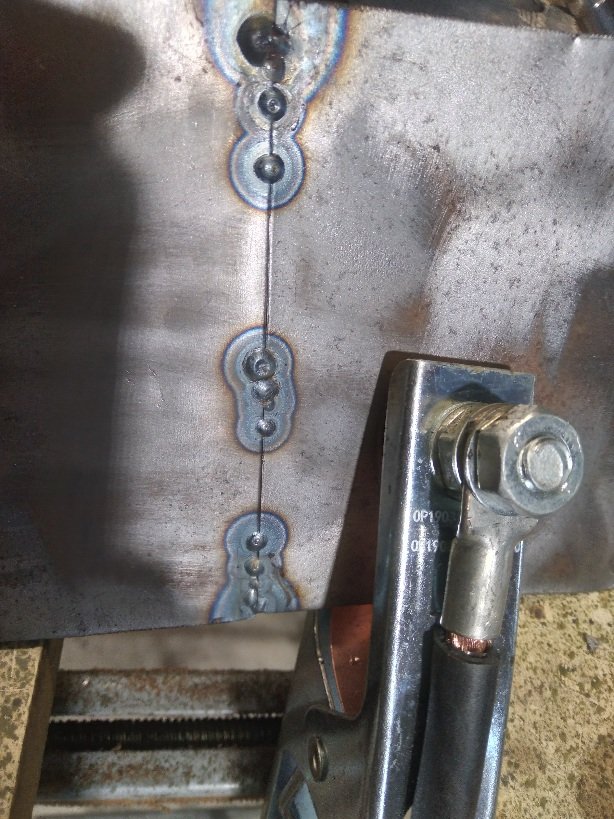

Right lads, got the welder out and cracked out this practice welds using the recommended settings. Actually pretty happy with them for a practice weld. Problem is though , if I use this setting on the escort itself I I blow holes. Hopefully that is rectified by practice though . Cheers, opinions and criticism welcome !

-

Yeah but small difference ... Your welds look mint ! Will post up settings when I do it. Thanks

-

I haven't forgotten lads. Just cut some panel steel to practice on. Will do it in weekend as ran out of time tonight. Heres a couple pics of my setup. Cheers for all the advice so far

-

Funny , they are exactly the guys I've been following on youtube.

-

Ok thanks bling ! I do get what you mean but some pics would be grand ! It's mainly the welder setting I think I'm struggling with. I've only had the welder about 4 months using it on and off.

-

Thanks guys. I will stop welding the eskie and start practicing again on some practice steel as u suggest. I have set the welder to what the information sheet in the welder suggested but thought it was too hot as it was blowing holes. I have put several patches in but it's when I go to blend or grind my welds down , I get pinholes and cant take the welds back far enough for them too look neat and tidy. I think I'm welding too cold because I'm scared of blowing holes . Also do you guys use flap discs or backing plates on your grinder with sandpaper discs on it. Thanks in advance.

-

Sorry , I have a cigweld weldskill 185 and I'm using co2 gas. I'm welding panel steel.

-

Sorry for interrupting thread but how do you guys practice your welds and learn the welder. Been welding in patches but not that satisfied with end result.

-

77 ford escort panel van. Jusepys 77 ford escort panel van

Jusepy82 replied to Jusepy82's topic in Projects and Build Ups

Tiny update tonight. Brought some LED lights on a tripod tonight from bunnings. Stoked with how much light they are pumping out. When welding I cannot see without holding a torch on the site of my welds. Cant go wrong for under 70bucks.- 65 replies

-

- 10

-

-

Hey guys , How much stick out do you have when you are mig welding ?

-

77 ford escort panel van. Jusepys 77 ford escort panel van

Jusepy82 replied to Jusepy82's topic in Projects and Build Ups

-

77 ford escort panel van. Jusepys 77 ford escort panel van

Jusepy82 replied to Jusepy82's topic in Projects and Build Ups

Right so tonight I decided to weld in my panel. I havent ground it bk yet but I'm pretty happy with it inside and out ! I've been practicing my welding abit durning the week. Not the best but way better than the last attempt. -

77 ford escort panel van. Jusepys 77 ford escort panel van

Jusepy82 replied to Jusepy82's topic in Projects and Build Ups

Soooooo today I decided to tackle this pannel again. I cut out the offending pannel and started making the replacement replacement pannel . Here's a couple of pics , I brought a few new tools to help me be a better pannel maker. A comma beating dolly and a flat pannel beater hammer! Thanks for reading -

Nice work man , very inspirational and gives me much motivation. Thanks

-

For some reason I thought that there had to be a little gap so the weld penetrated through and if it expanded with the heat it wouldnt warp the pannel. Lesson learned... thanks lads ! I'm yet to tackle it again , this weekend looks promising though.